Independent oil supply structure for oil recess inside and outside primary shaft gathering ring bearing of high-speed machine tool

A technology of machine tool spindle and floating ring bearing, which is applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of limited high-speed performance, short service life, shaft holding, etc., and achieves a simple and reasonable overall structure. The effect of high operating speed and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

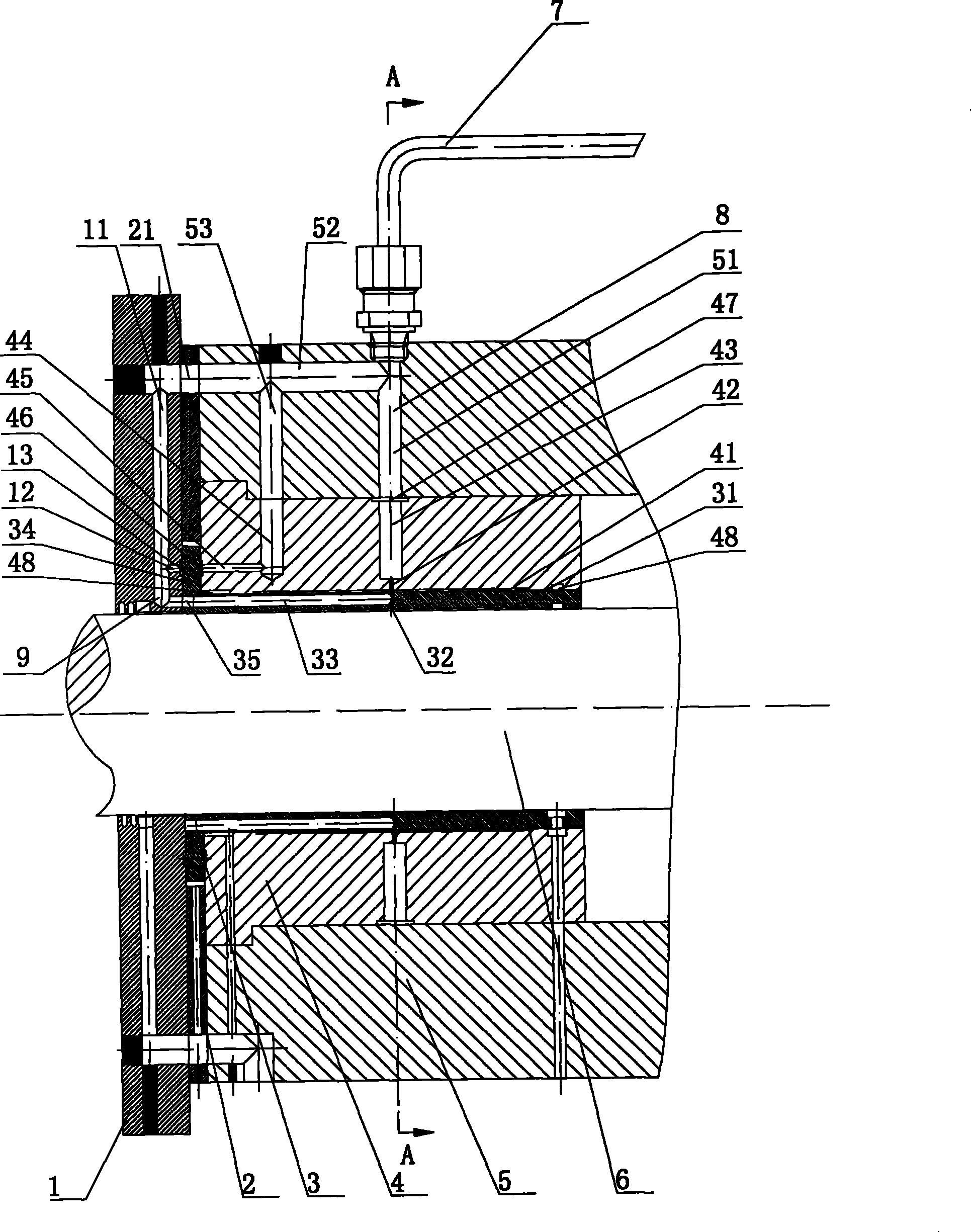

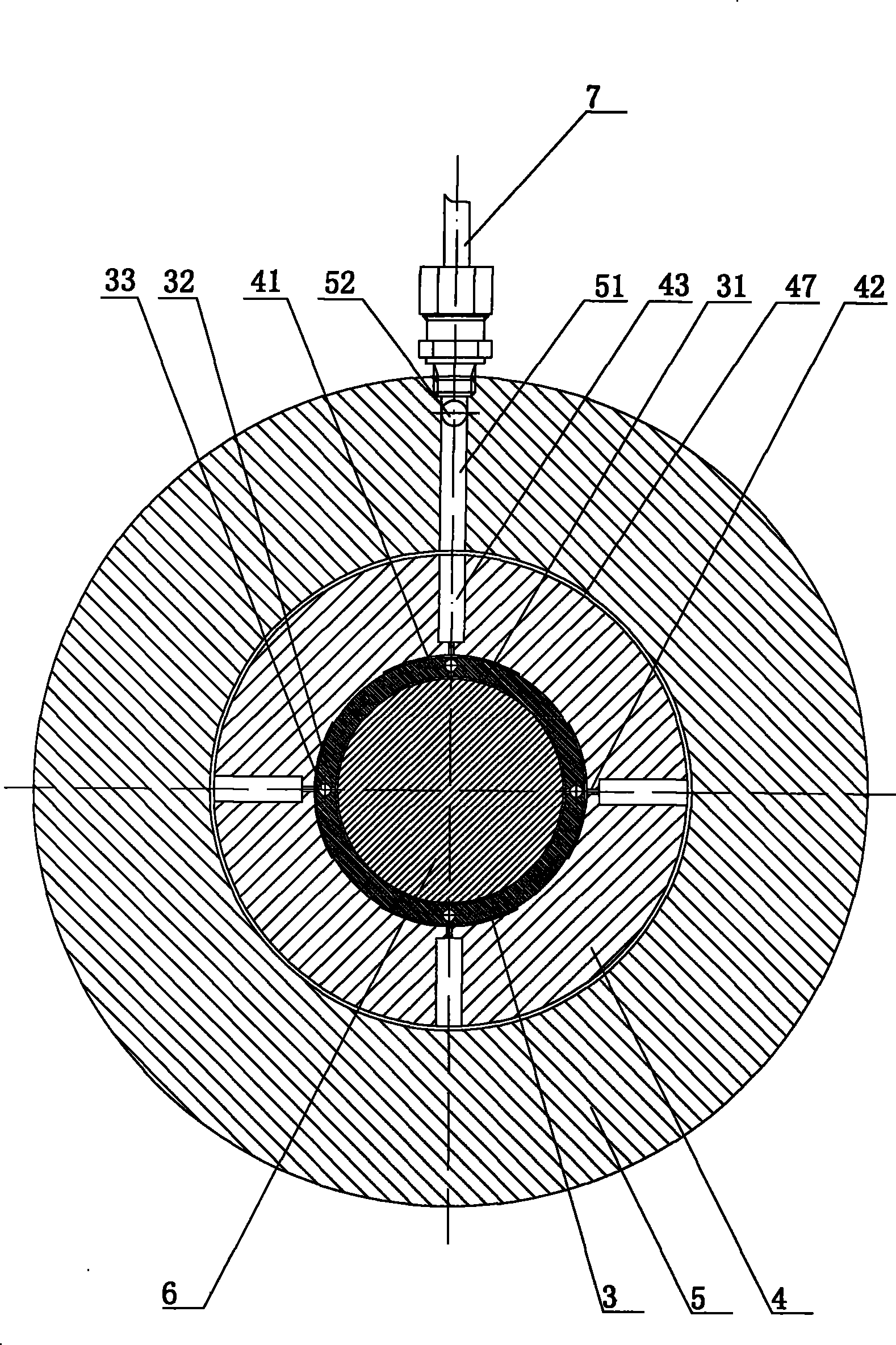

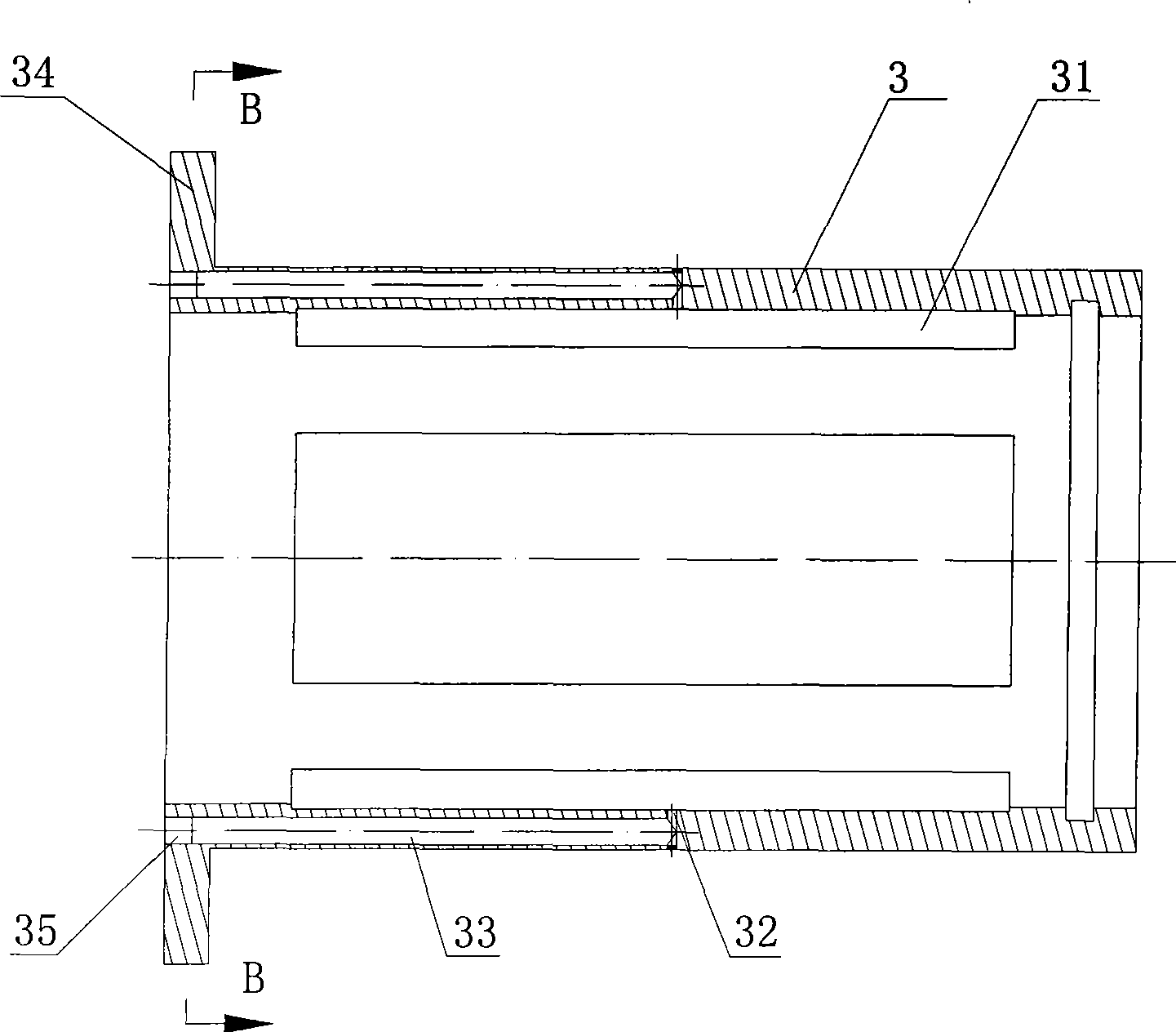

[0034] Such as Figure 1 to Figure 4 As shown, the independent oil supply structure of the inner and outer oil chambers of the floating ring bearing of the high-speed machine tool spindle of the present invention is provided with a bearing oil chamber 41 on the inner wall of the bearing 4 sleeved in the bearing seat 5, as a part of the entire floating ring bearing system The outer oil chamber is provided with a floating ring oil chamber 31 on the inner wall of the floating ring 3 sleeved in the bearing 4, as the inner oil chamber of the entire floating ring bearing system, the main shaft 6 is sleeved in the floating ring 3, and the bearing housing 5 End cover 1 and gasket 2 are installed at the end of the floating ring 3. The gasket 2 is sleeved on the thrust ring 34 of the floating ring 3, and is located between the end cover 1 and the bearing seat 5. The gap between the two sides of the thrust ring 34 It can be adjusted by the thickness of the gasket 2. At the same time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com