LED line lamp

A technology of LED line lights and LED packaging, which is applied in the direction of damage prevention measures for lighting devices, lighting devices, light sources, etc., and can solve problems such as gaps in the connection positions, easy breakage of the welding points of the lines, and inability to cooperate with plastic pipes. To achieve the effect of reliable and safe circuit connection, firm connection and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

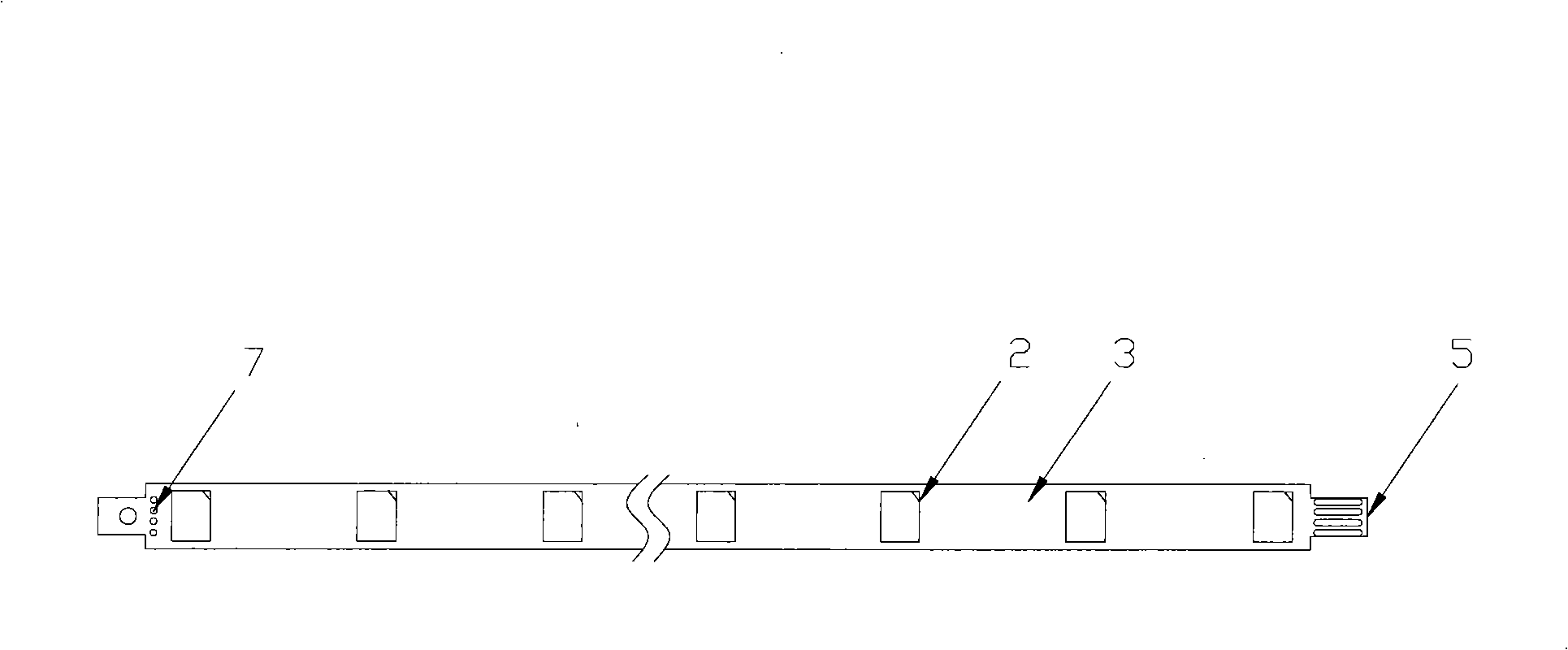

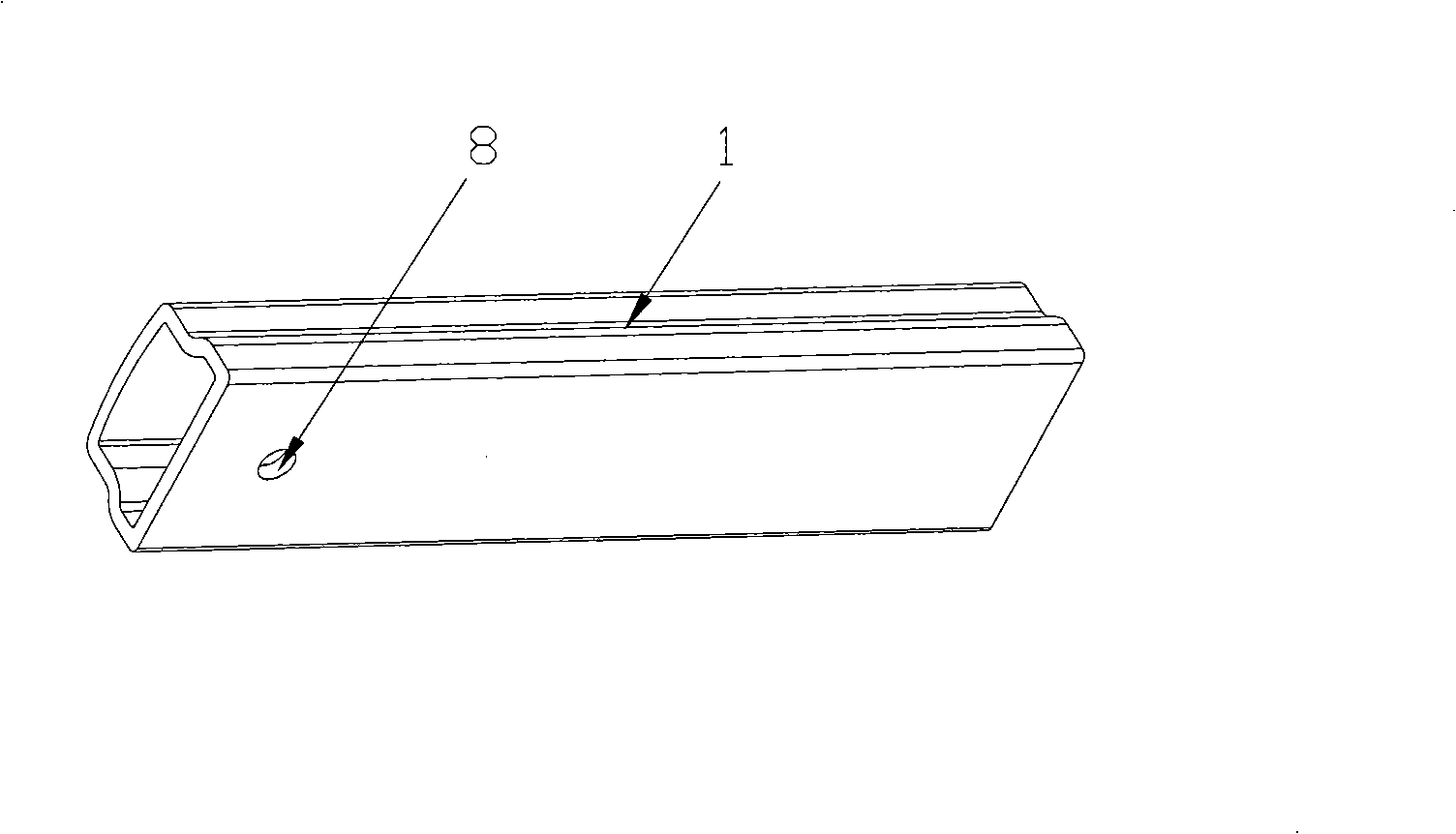

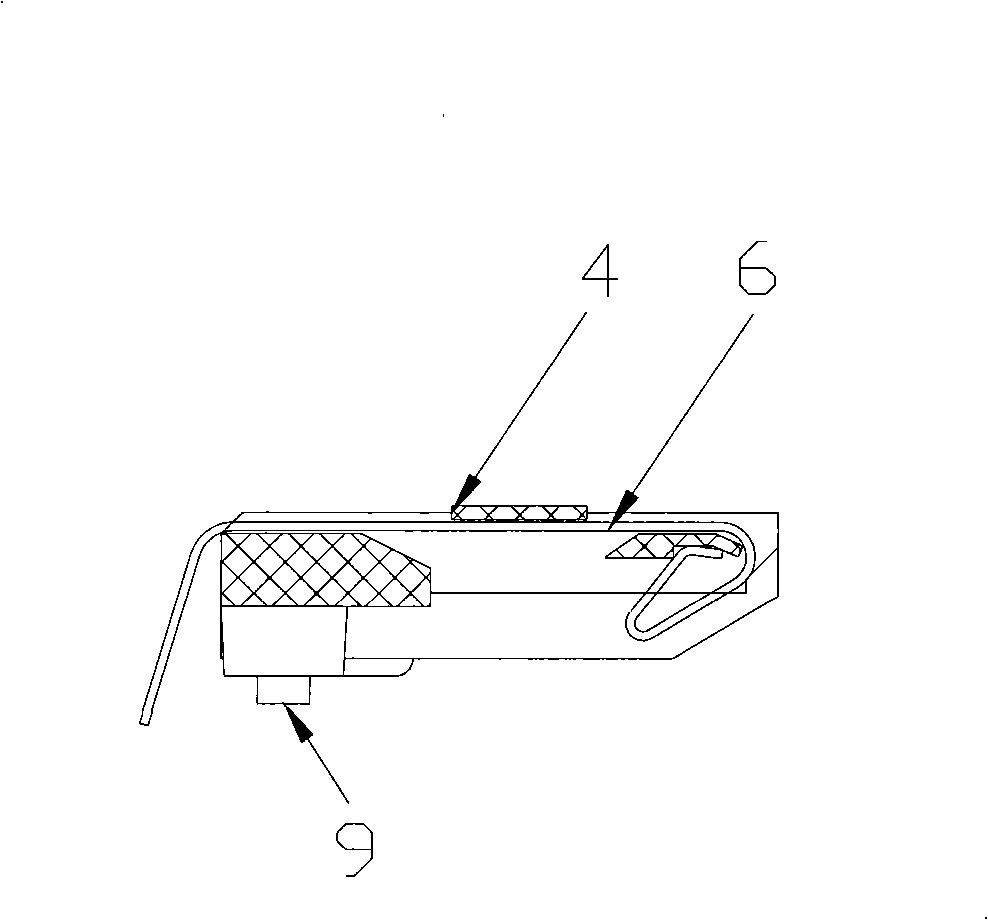

[0015] An LED line light, which is composed of several light bars connected to each other. The light bar includes a plastic tube shell 1, several LED packaging units 2, and a PCB circuit board 3 for installing the LED packaging units. The light bar The connectors are connected to each other through a connector, and the connector is composed of an insulating shell 4 that cooperates with each other and a metal sheet that is fixed in the insulating shell and is in contact with each other, and the metal sheet is electrically connected with the PCB circuit board 3 .

[0016] For the structure diagram of PCB circuit board, please refer to the attached figure 1 A plurality of LED packaging units 2 are packaged on a PCB circuit board 3 , one end of the PCB circuit board 3 is connected to the flat metal sheet 5 , and the other end is provided with a welding hole 7 for welding with the elastic metal sheet 6 . The LED light in the LED packaging unit adopts 5050 full-color or 5050 single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com