DC motor

A technology of DC motors and armatures, which is applied in the direction of circuits, collectors, electrical components, etc., can solve the problems that hinder the miniaturization and thinning of motors, the axial size and space of multiple motors, and increase the weight of motors, so as to achieve light weight , short service life, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

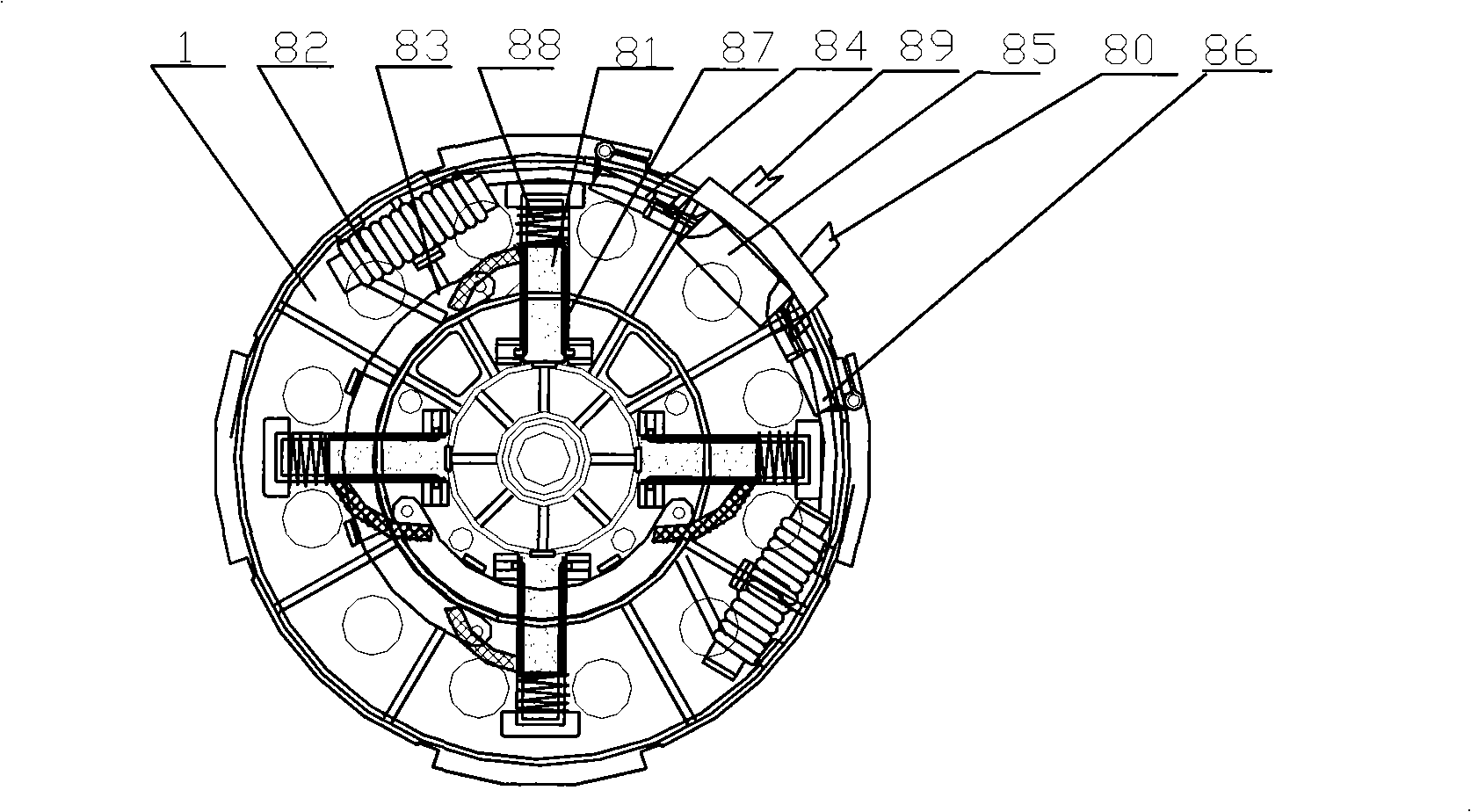

[0023] see Figure 5 , the DC motor of the present invention includes a casing 91 , an armature 92 , a stator 93 , a front end cover assembly 94 and a rear end cover assembly 95 . Wherein the rear end cover assembly includes an integral motor rear end connection part 1 with the rear end cover structural features of the commonly used motor and the brush basin structural feature and the electrical components assembled on the connection part; the shaft head 921 of the armature 92 is Internally threaded shaft. A heat-resistant and wear-resistant plastic cover 96 (used as a rear bearing) is assembled on the motor rear end connection part 1 .

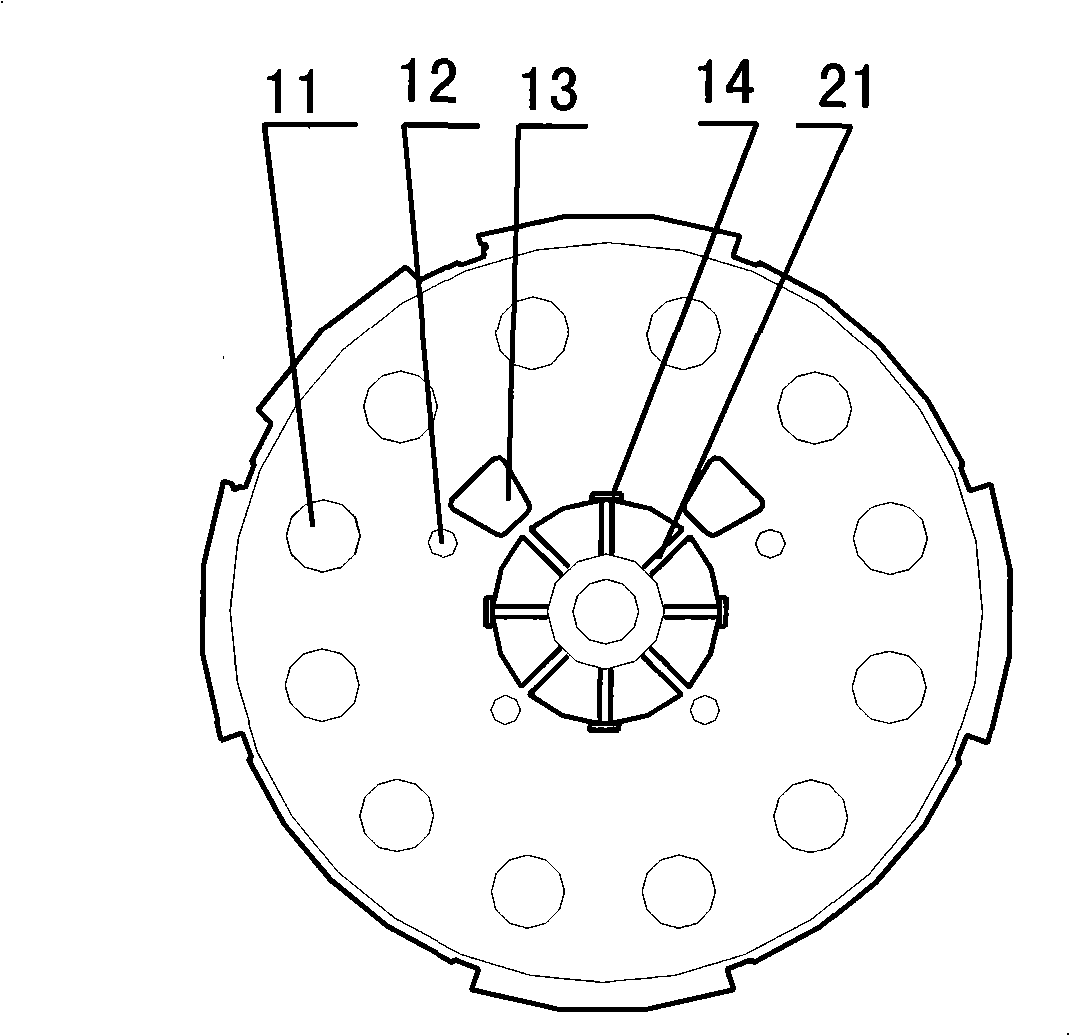

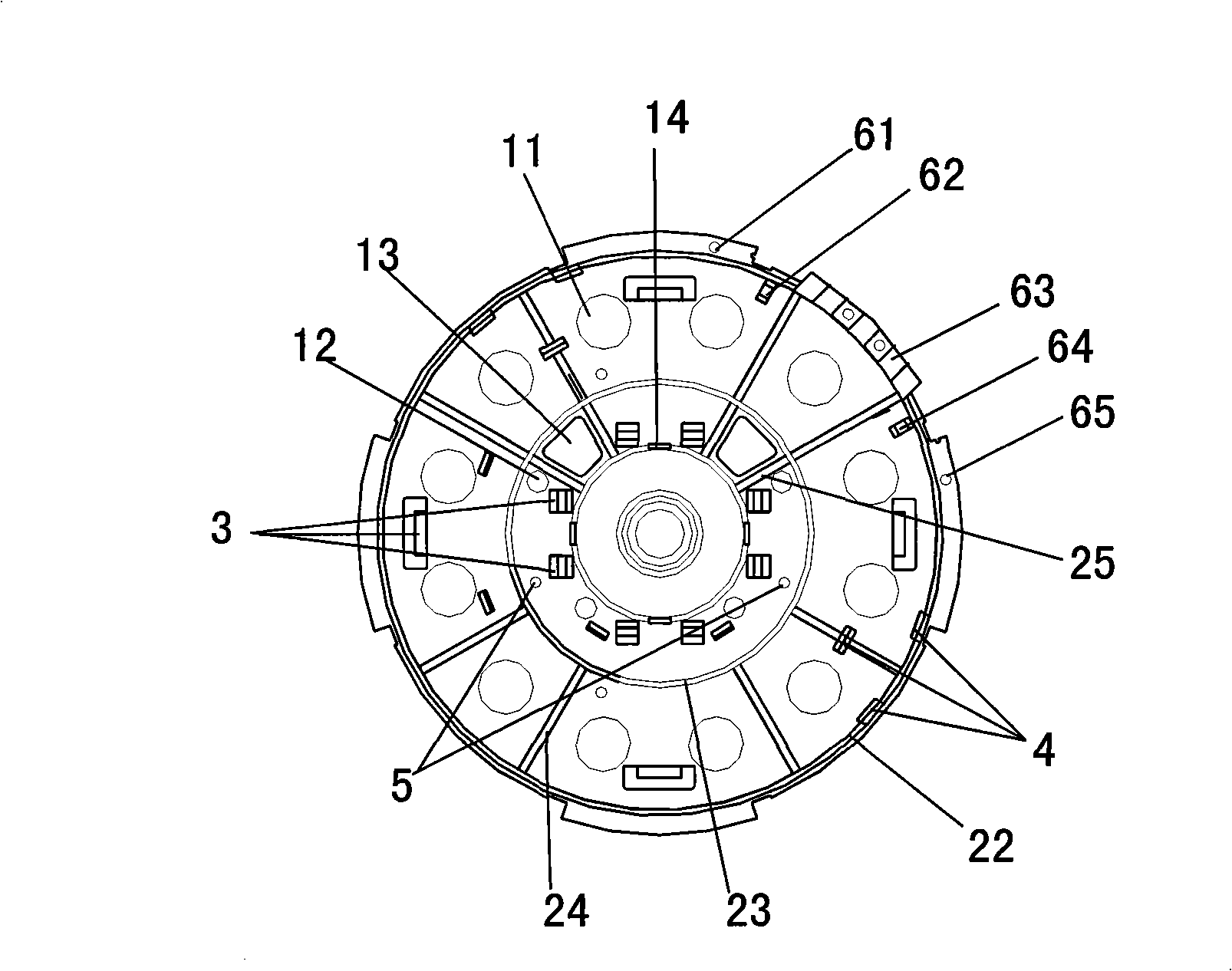

[0024] The integral motor rear end connection part 1 in the present invention is an injection-molded plastic structural part. Its specific structure is as figure 1 , figure 2 shown. A plurality of ventilation holes and a plurality of reinforcing ribs are provided on the connecting part 1 at the rear end of the motor, wherein a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com