Vibration energy collector with piezomagnetic/piezoelectric composite energy conversion structure

A technology of vibration energy harvesting and magnetoelectric transducers, applied in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, piezoelectric/electrostrictive/magnetostrictive devices, etc., can Solve the problems of high battery cost, obstacles to power supply, inability to use wired power supply, etc., and achieve high magnetoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

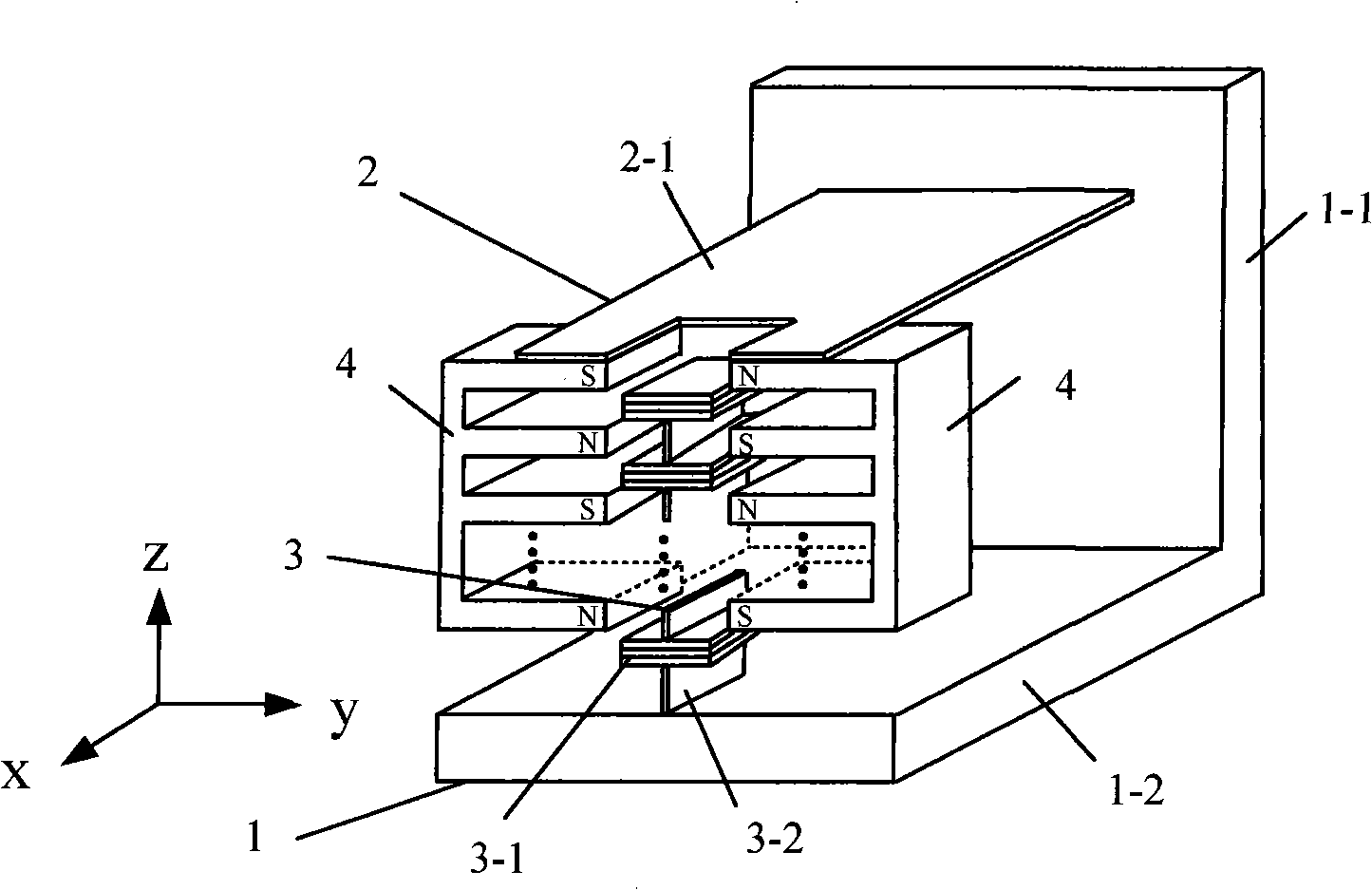

[0031] See attached figure 1 , as shown in the figure, the devices used in this example include: "L"-shaped support mechanism 1, plate-shaped elastic cantilever beam 2-1, block-shaped laminated transducing structure 3-1 and plate-shaped rib 3-2 Composed of piezoelectric / piezoelectric composite magnetoelectric transducer 3, two symmetrical interdigitated permanent magnet magnetic circuits 4, the interdigitated fingers are placed opposite each other, and the upper ends of the two interdigitated permanent magnet magnetic circuits 4 are fixed on the elastic One end of the lower side of the cantilever beam 2-1, and the other end of the elastic cantilever beam 2-1 are fixed on the support 1-1 of the "L"-shaped support mechanism 1, and the piezoelectric / piezoelectric composite magnetoelectric transducer 3 passes through the rib plate 3-2 is connected and fixed on the base 1-2 of the "L"-shaped support mechanism 1 through the rib plate 3-2, and the piezoelectric / piezoelectric composit...

example 2

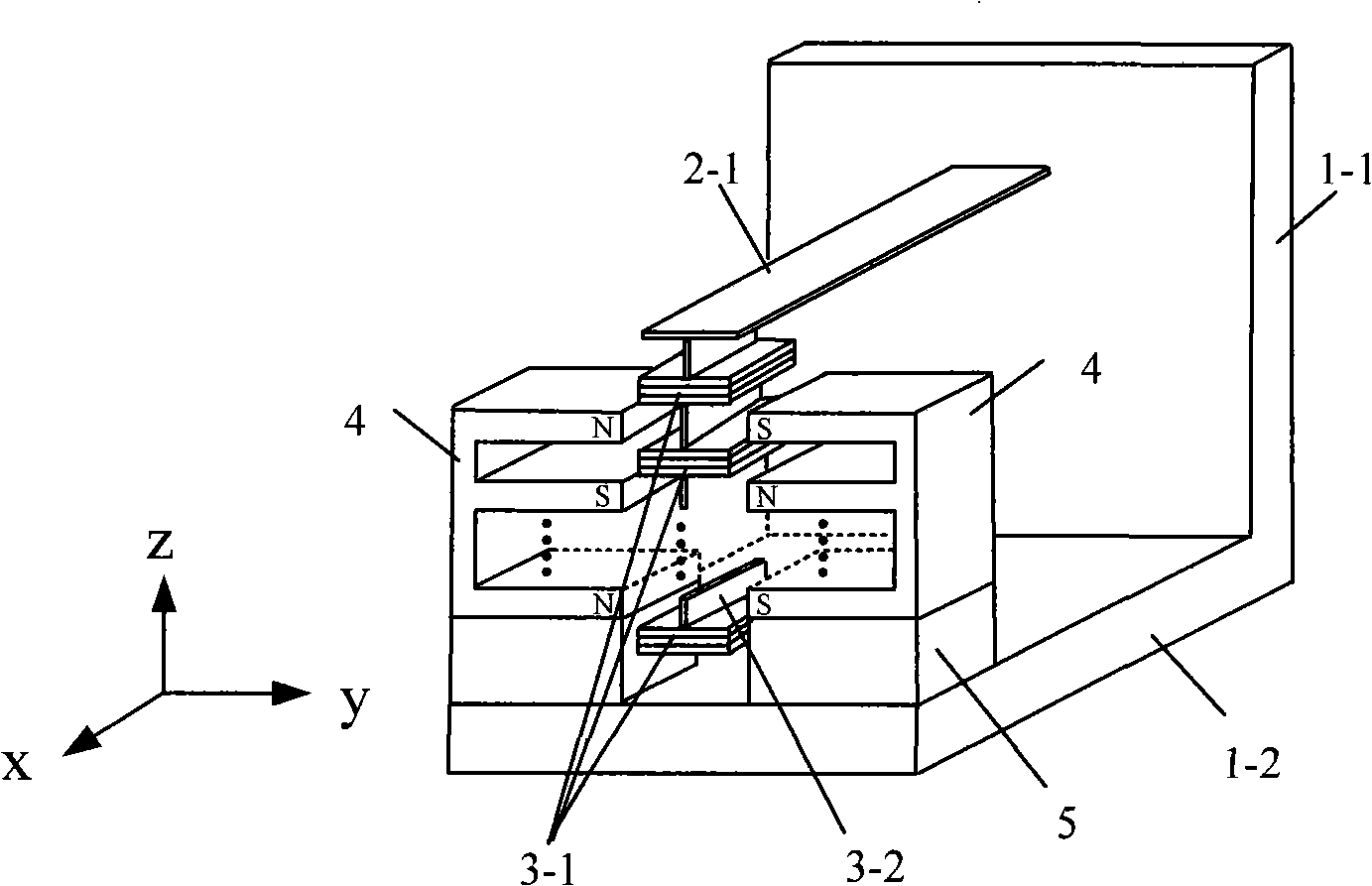

[0037] See attached figure 2 , it differs from Embodiment 1 in that: the introduction of non-magnetic material 5 is used to connect the lower ends of the two interdigitated permanent magnet magnetic circuits 4 with the base 1-2; what is fixedly connected with the elastic cantilever beam 2-1 is a pressure The magnetic / piezoelectric composite magnetoelectric transducer 3, the upper end of the rib plate 3-2 of the piezoelectric / piezoelectric composite magnetoelectric transducer 3 is fixed on one side of the lower side of the elastic cantilever beam 2-1.

[0038] When the elastic cantilever beam 2-1 drives the laminated transduction structure 3-1 and the permanent magnet magnetic circuit 4 to produce reciprocating relative motion, the piezomagnetic layer in the laminated transduction structure 3-1 enters regions with different magnetic induction intensities, The y-axis in the chemicalization direction produces stretching deformation, and this mechanical motion is transmitted to t...

Embodiment 3

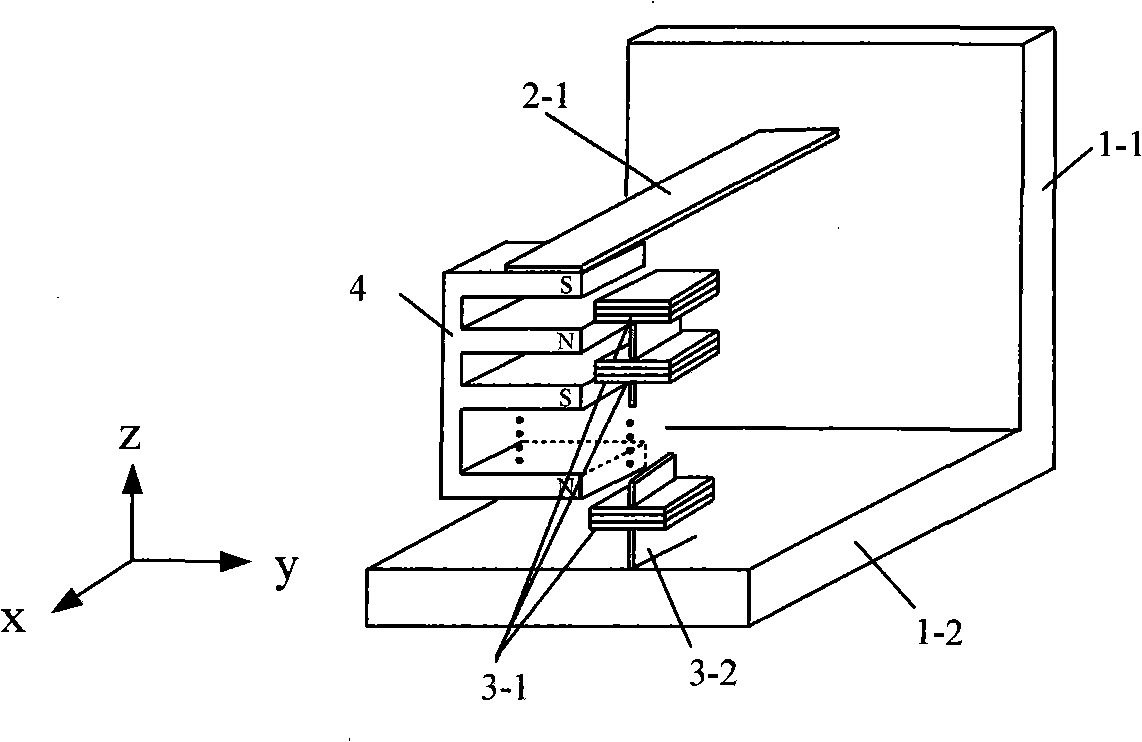

[0040] See attached image 3 , the structure of this example is different from Embodiment 1 in that: the two interdigitated permanent magnet magnetic circuits 4 are replaced by a single interdigitated permanent magnet magnetic circuit 4; when excited by external vibration, the elastic cantilever beam 2- 1 drives the unilateral interdigitated permanent magnet magnetic circuit 4 to reciprocate, and the principle of electromechanical conversion is the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com