Ferromagnetic silicon carbide crystal and preparation method thereof

A silicon carbide and ferromagnetic technology, applied in the field of ferromagnetic silicon carbide crystals and its preparation, to achieve high magnetoelectric conversion efficiency, uniform P-type elements, and uniform stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

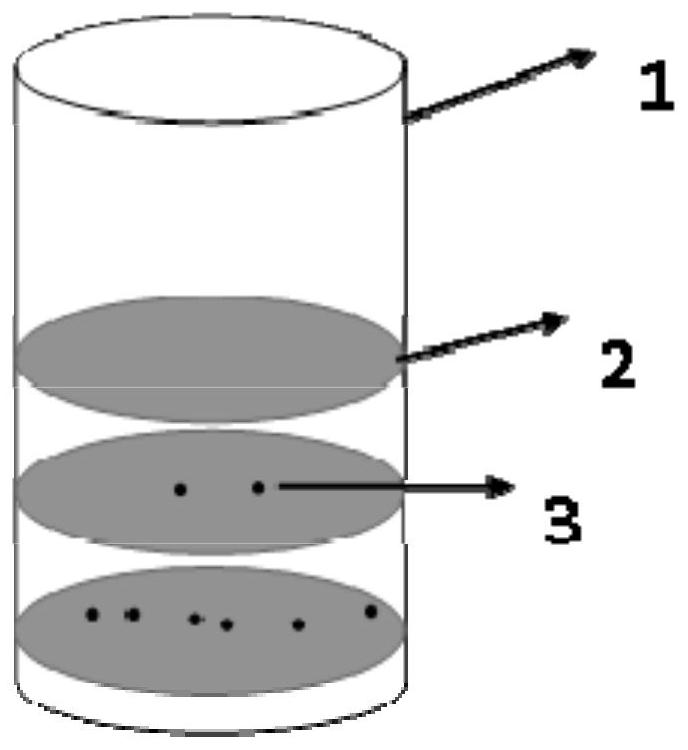

[0077] by figure 1 The illustrated embodiment of three silicon carbide wafers is to illustrate the method for preparing ferromagnetic silicon carbide crystals of the present application, but is not limited to three silicon carbide wafers.

[0078]As an embodiment, the preparation method of ferromagnetic silicon carbide crystal comprises the following steps:

[0079] 1) Assembly steps: medium frequency induction heating is used for crystal growth, and the crucible is assembled before heating. The specific assembly is to adopt a layered charging method, and Al with a boiling point (decomposition point) of 2200 ° C 4 C 3 Place 0.3g between the upper and middle silicon carbide wafers, and 0.6g between the middle and lower layers; the thicknesses of the upper silicon carbide wafer, middle silicon carbide wafer, and lower silicon carbide wafer are 500μm, 450μm, and 400μm in sequence;

[0080] 2) Crystal growth:

[0081] a. Vacuum removal: vacuum the furnace to 10 -6 Below mbar, ...

Embodiment 2

[0089] The difference between this embodiment and embodiment 1 is that the Al in the raw material is adjusted 4 C 3 The concentrations of the doped aluminum ions and the generated holes in the prepared silicon carbide crystals were tested respectively, and the ferromagnetic silicon carbide crystals 2#-5# were respectively prepared, compared with the ferromagnetic silicon carbide crystals D1#-D2# , see Table 1 for details.

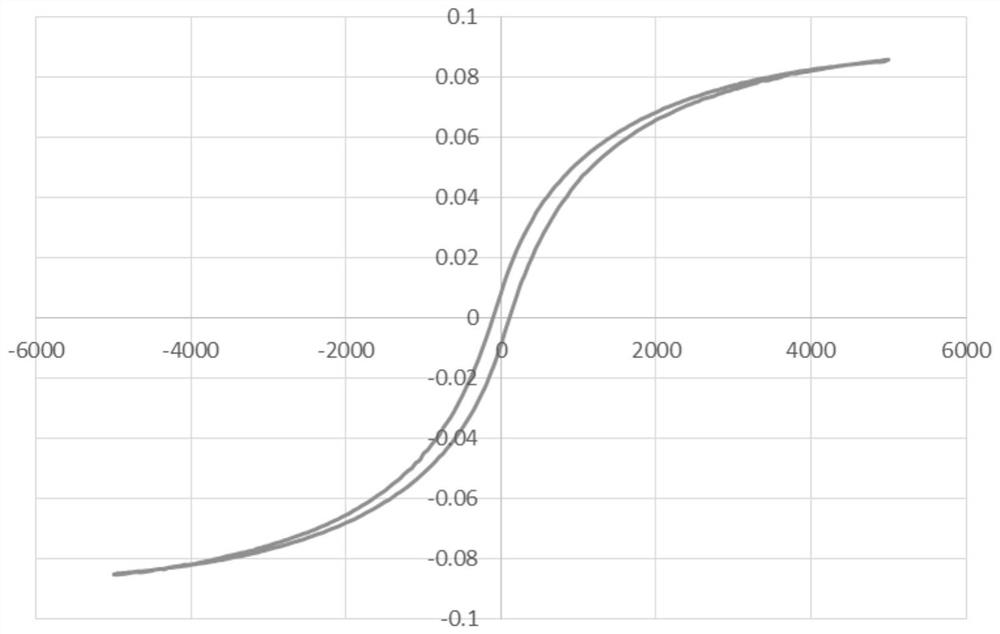

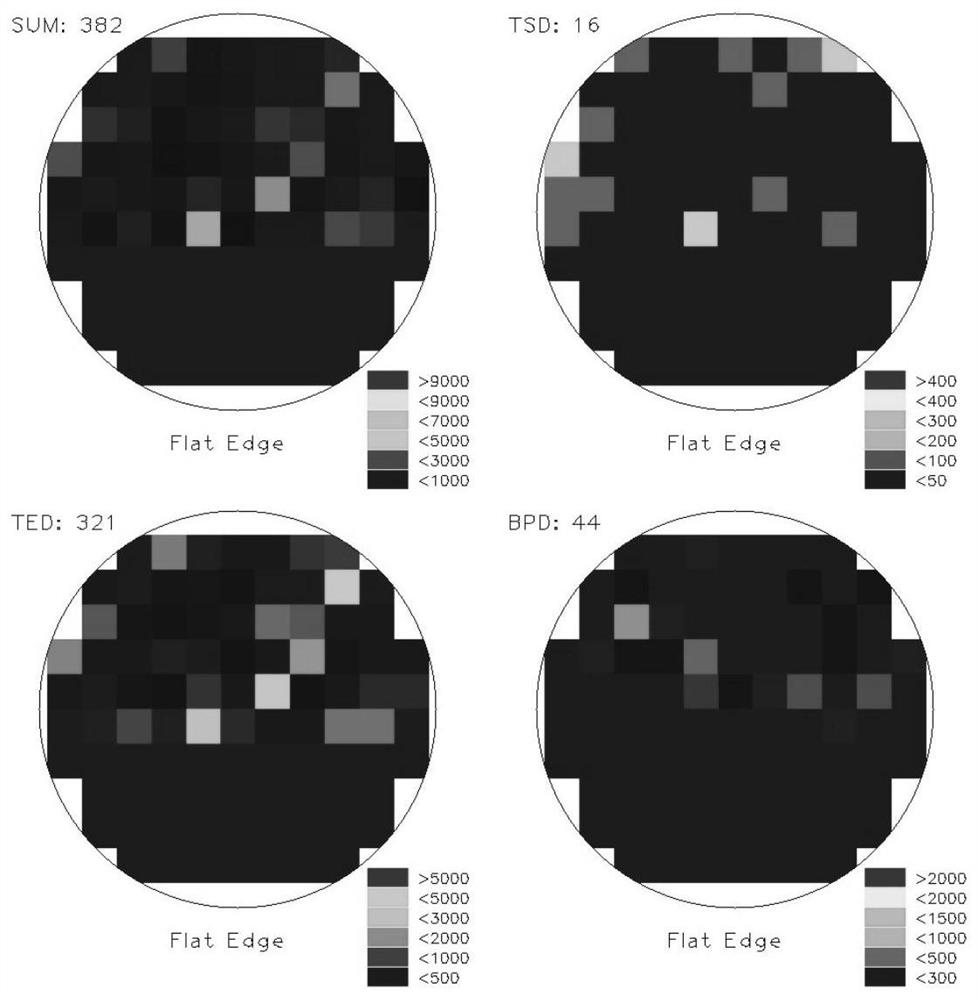

[0090] Test the obtained ferromagnetic silicon carbide crystals 1#-5# and comparative ferromagnetic silicon carbide crystals D1#-D2# respectively: magnetization curve (can judge whether it is ferromagnetic, saturation magnetization value), SIMS test aluminum ion concentration, Hall test carrier concentration, resistivity and its distribution, and XRD.

[0091] Take the test result of ferromagnetic silicon carbide crystal 1# as an example to illustrate the performance of the ferromagnetic silicon carbide crystal of the present application:

[0092] figu...

Embodiment 3

[0101] The method for preparing ferromagnetic silicon carbide crystals in this embodiment differs from that in Example 1 in that:

[0102] 3) Cavitation control: After growing for 20 hours in step c2, open the nitrogen valve to control the flow rate to 4 sccm / min, and evenly pass it into the growth chamber for 30 hours until the crystal growth process is completed, that is, the ferromagnetic silicon carbide crystal 6# is obtained.

[0103] Since nitrogen doping introduces a gap with the atomic diameter of silicon carbide to enter holes, the introduction of holes and the dopant atoms work together to contribute to the ferromagnetism of silicon carbide crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com