Transmission unit for vehicles

A technology for transmissions and vehicles, applied in transmissions, differential transmissions, control devices, etc., can solve problems such as transmission damage and deterioration of meshing behavior.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

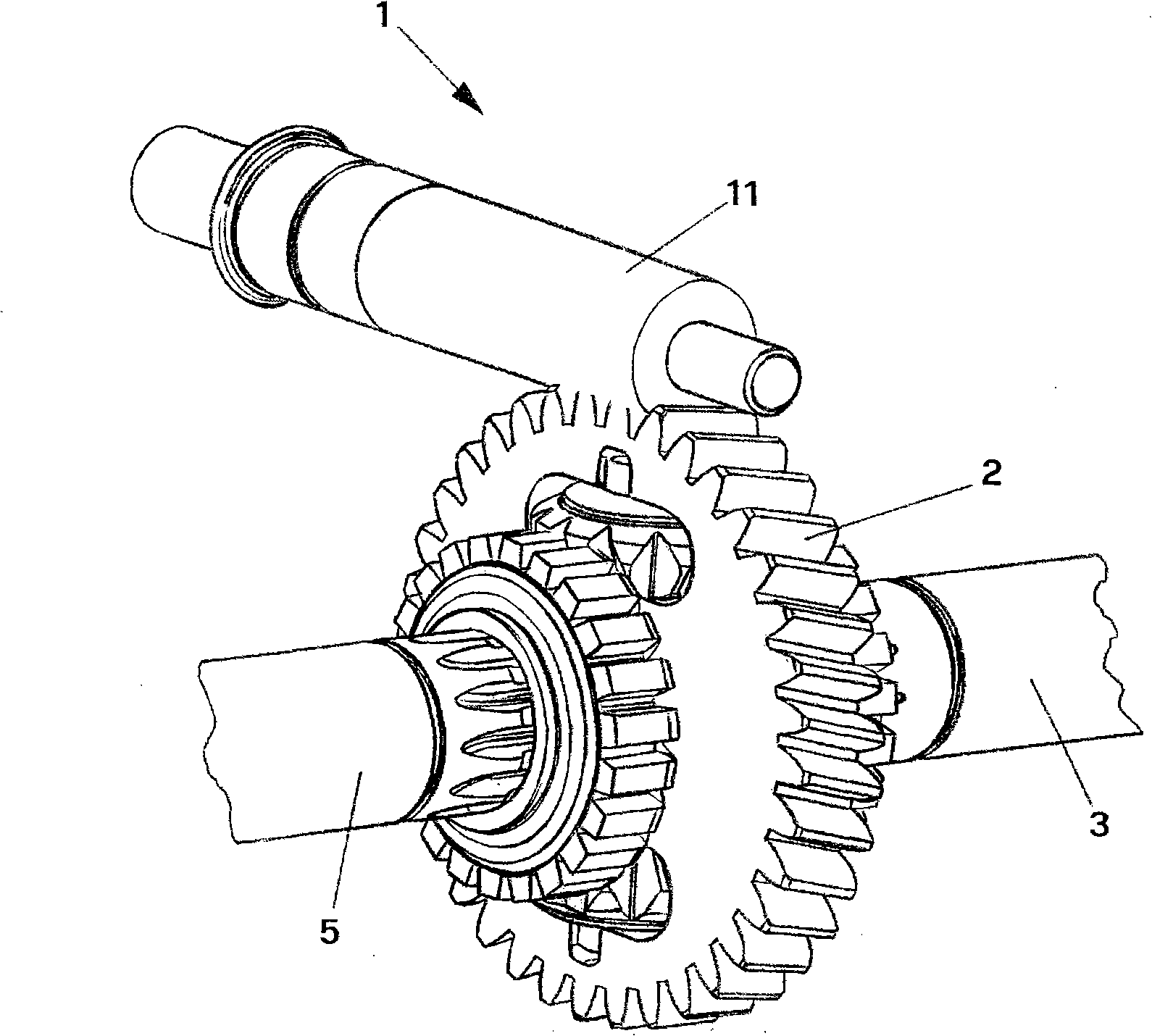

[0028] With reference to the above drawings in particular figure 1 , it can be seen that the transmission device of the present invention includes a drive shaft generally marked as 1, and a pinion 11 meshing with the crown gear 2 is arranged on the end of the drive shaft.

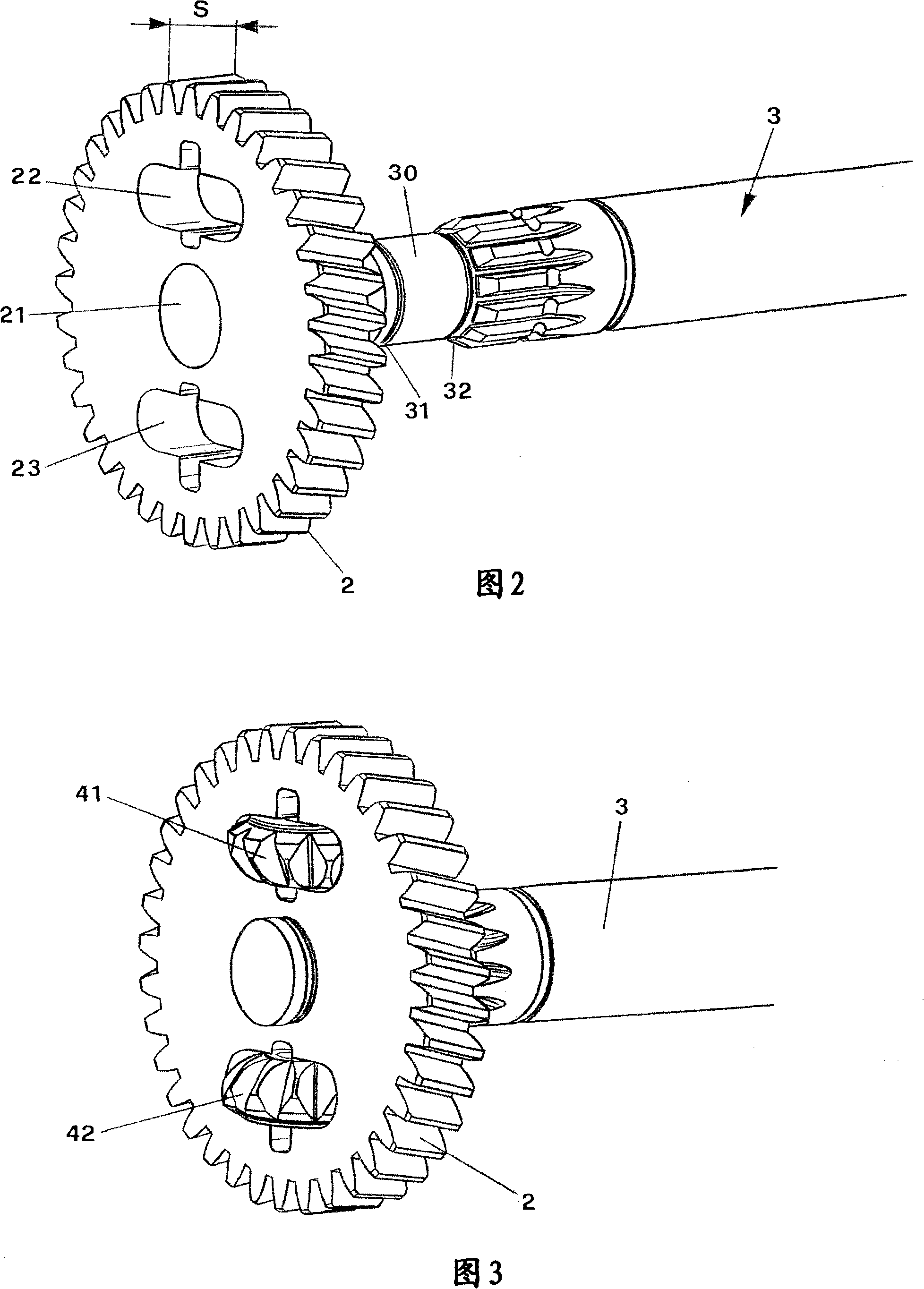

[0029] As shown in more detail in FIG. 2, the crown wheel has a central bore 21 adapted to receive a drive shaft and two identical and opposite cavities 22 and 23, which, as will be explained below, 23 accommodate the same number of planetary gears.

[0030] The crown wheel 2 is preferably made of copper in order to facilitate the machining of the gear teeth, the abutments 21 , 22 and 23 and also the meshing of the gear teeth with the pinion 11 of the drive shaft 1 .

[0031] The end 30 of one of the two driving shafts marked 3 is longer than the thickness S of the crown wheel 2 .

[0032] The diameter of said end 30 is substantially equal to the diameter of the bore 21 of the crown wheel, but with limite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com