High-density bamboo beaverboard

A bamboo fiber and high-density technology, which is applied in the pretreatment of molding materials, household components, flat products, etc., can solve the problems of narrow use range, easy deformation, low density, etc., achieve uniform density and texture, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific production examples:

[0024] 1. The moso bamboo slices bought in the market are first selected for carbonization.

[0025] 2. The selected moso bamboo sheets are rolled into flake-like strips (about 2×20×1950mm in size) that are broken in the fiber direction.

[0026] 3. Put the bamboo slices into the carbonization furnace for surface treatment such as carbonization.

[0027] 4. Put the bamboo slices into the drying room to dry to make the moisture content below 13%.

[0028] 5. Put the bamboo slices in the phenolic resin adhesive for dipping. After dipping for 6-10 minutes, take out the bamboo slices, drain them, and then put them in a chain drying room at 50-70°C to dry to make the moisture content Reach 10-12%.

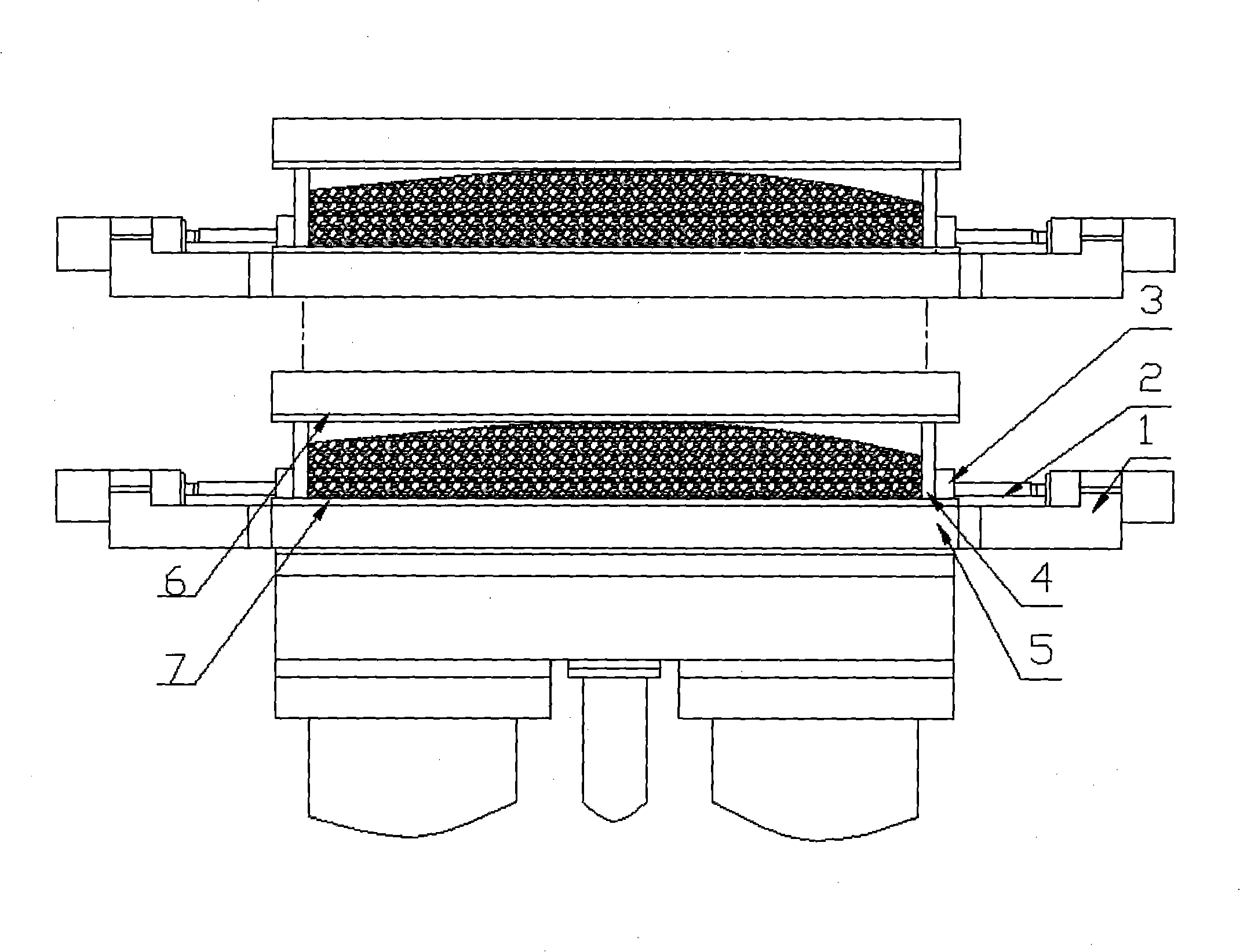

[0029] 6. The density of the finished bamboo board is 1.1-1.3g / cm 3 , the thickness is 80mm to calculate, weigh a proper amount of moso bamboo flake strips, arrange the flake strips vertically and orderly and put them into the multi-layer hot p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com