Crystal growth apparatus and method under vibration field

A technology of crystal growth and vibration field, applied in the field of material science, to achieve the effect of improving crystal quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described below by means of examples, but not limited to the following examples.

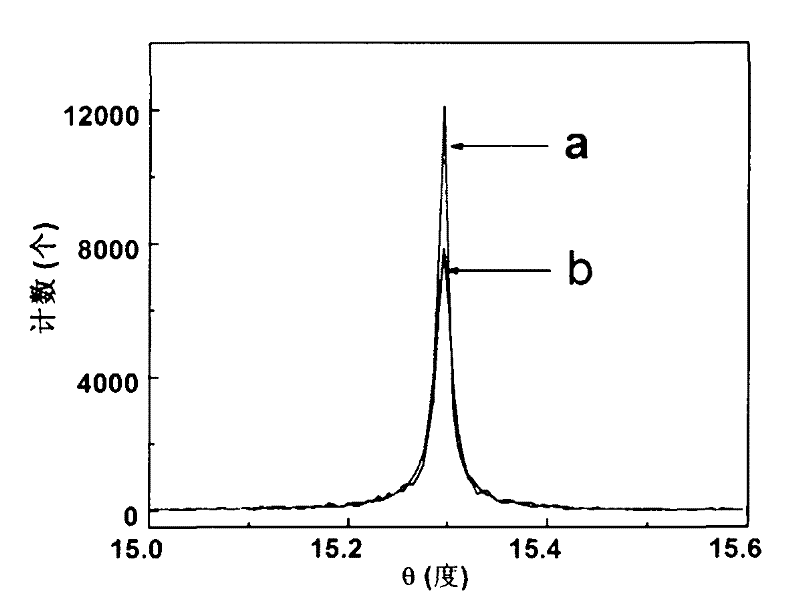

[0036] Example bismuth silicate (Bi 12 SiO 20 , BSO) single crystal growth.

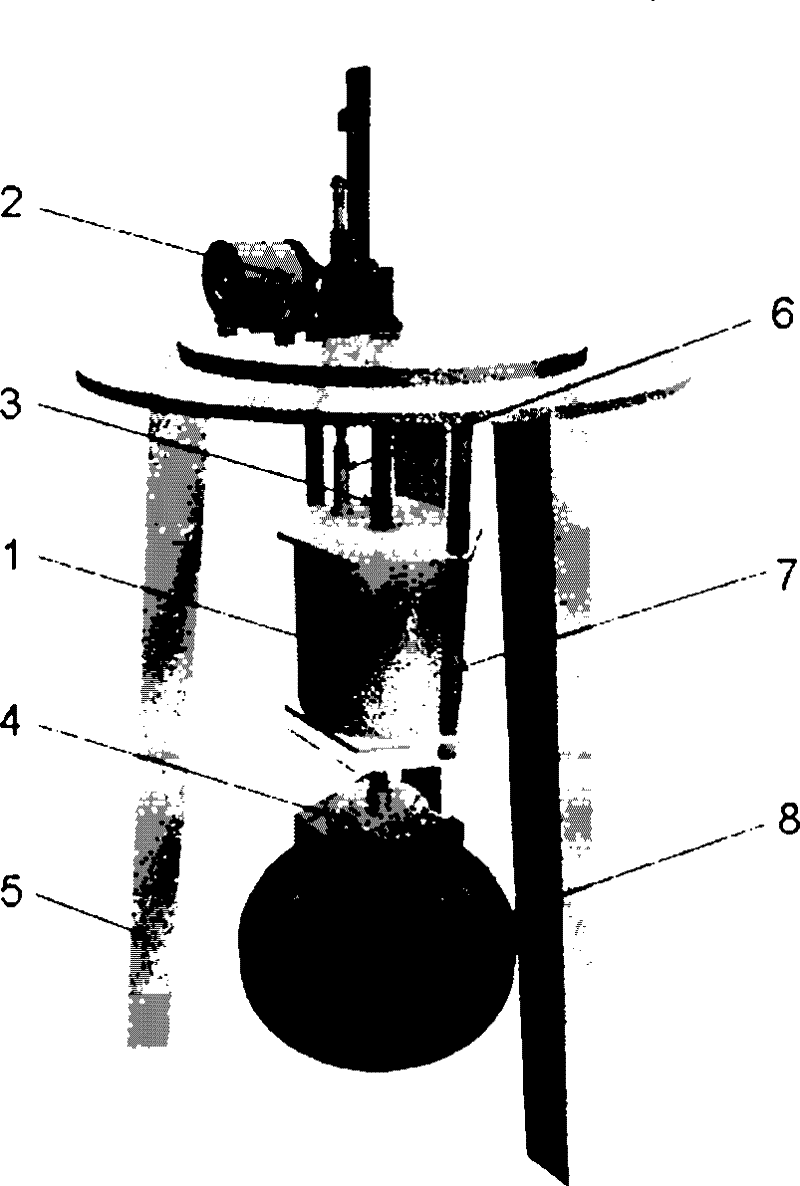

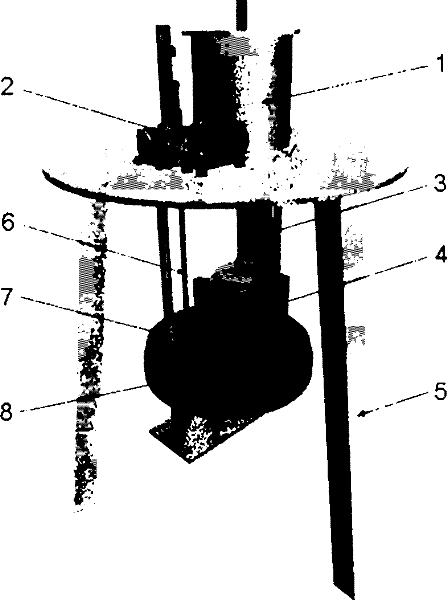

[0037] The components of the device are figure 1 The structures shown are assembled and fixed. The sample ampoule 3 containing the BSO raw material is passed through the furnace chamber of the furnace body 1, and its lower end is then fixedly mounted on the vibration generator 4 through threads. Start the transmission mechanism 2, drive the furnace body 1 to move axially to the calculated set initial position (depending on the temperature field distribution, the melting point of the material and the position of the seed crystal material), and close the transmission mechanism 2. Then, supply power to the furnace body 1 for heating, and keep it warm after reaching the growth temperature according to the set procedure. Then, turn on the transmission structure 2 again, set the moving sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com