Hydraulic cylinder-controlled oblique tray type plunger hydraulic transformer

A technology for hydraulic transformers and hydraulic cylinders, applied in the field of hydraulic components, can solve the problems of unfavorable system automatic flow and pressure accurate control, and the inability to realize displacement adjustment of electronically controlled quantitative hydraulic transformers, and achieve the effect of improving application performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

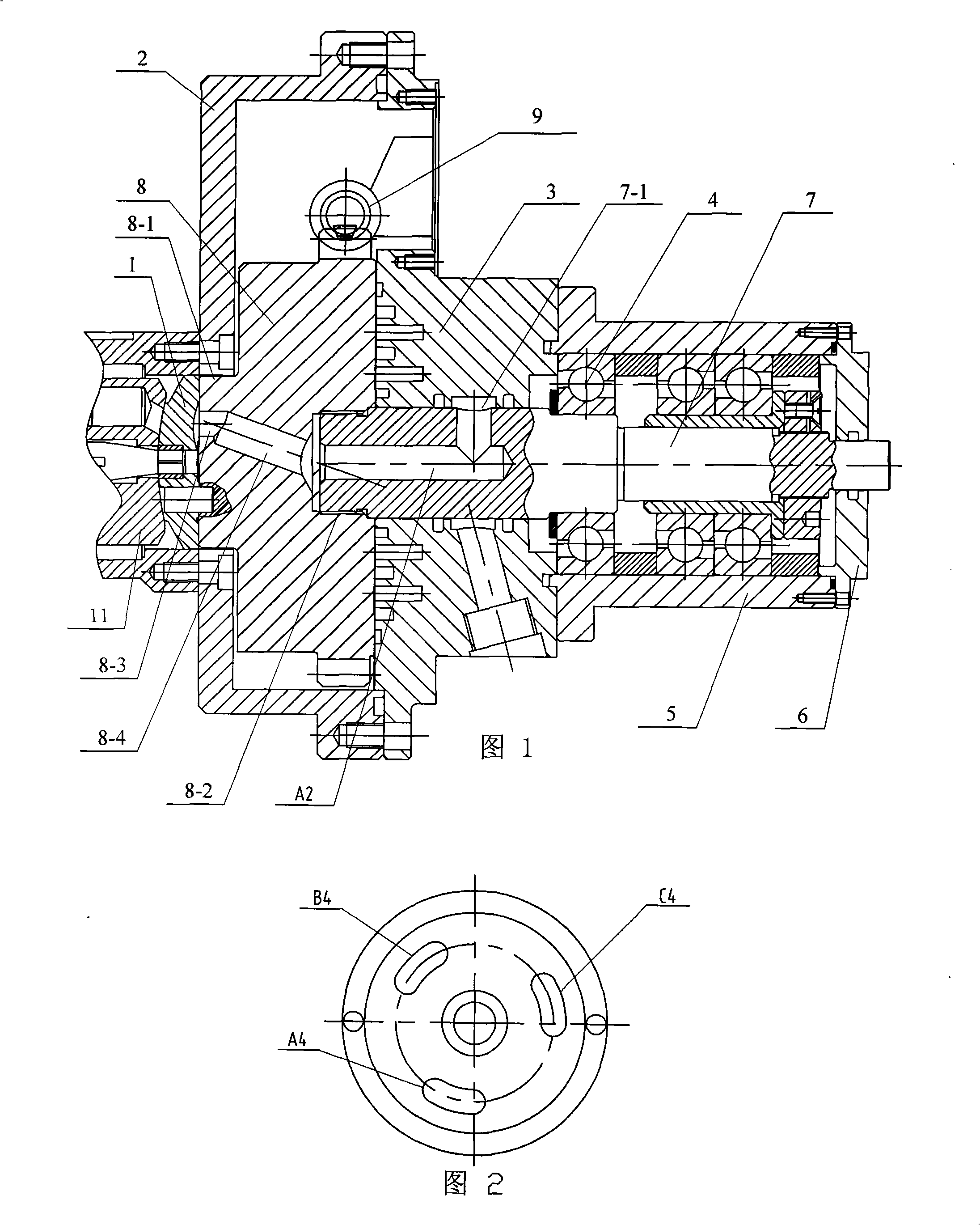

[0011] Specific Embodiment 1: This embodiment will be described with reference to FIGS. 1 to 10. The hydraulic transformer of this embodiment includes a front valve plate 1, a hydraulic transformer casing 2, an oil passage transition block 3, a bearing 4, a bearing seat 5, an end cover 6 and The main shaft 7; the hydraulic transformer also includes a rear distribution plate 8, a hydraulic cylinder 9 and a rack 10, the rear distribution plate 8 is installed in the hydraulic transformer shell 2, and the small-diameter end surface 8-1 of the rear distribution plate 8 is connected to the The front distribution plate 1 arranged on the outer side of the hydraulic transformer housing 2 is connected by pins, and the outer wall of the large-diameter end surface 8-5 side of the rear distribution plate 8 is processed with teeth along the circumferential direction. The hydraulic cylinder 9 is composed of a hydraulic cylinder body 9 -1 and two pistons 9-2, the rack 10 is installed in the hy...

specific Embodiment approach 2

[0012] Specific embodiment two: This embodiment is described in conjunction with Fig. 1, Fig. 8 and Fig. 9. The high-pressure oil hole A1 of the oil passage transition block 3 in this embodiment is a high-pressure oil hole inclined toward the direction of the rear distribution plate 8, and the oil passage Both the load oil hole B1 and the oil return tank oil hole C1 of the transition block 3 are L-shaped. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

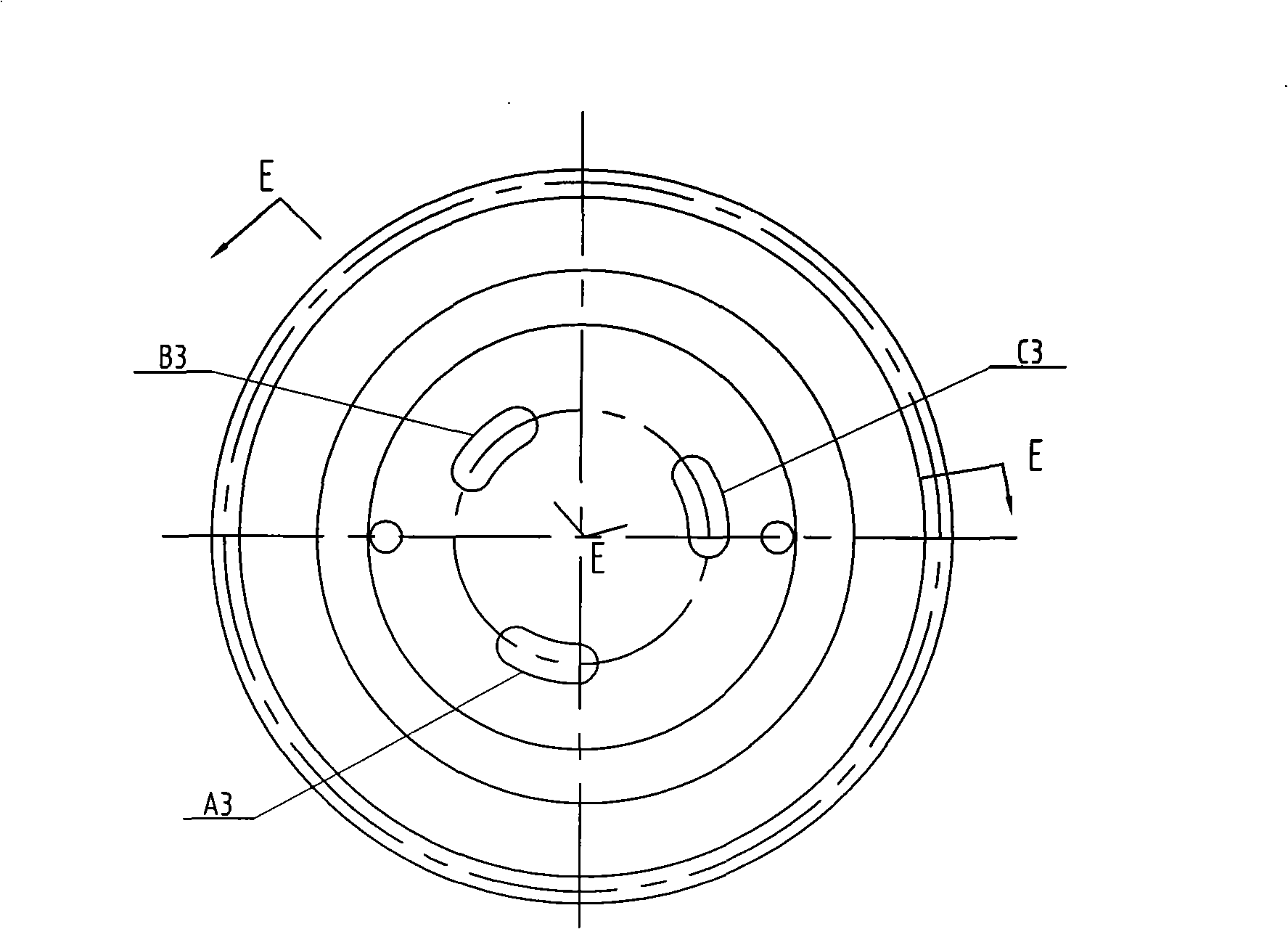

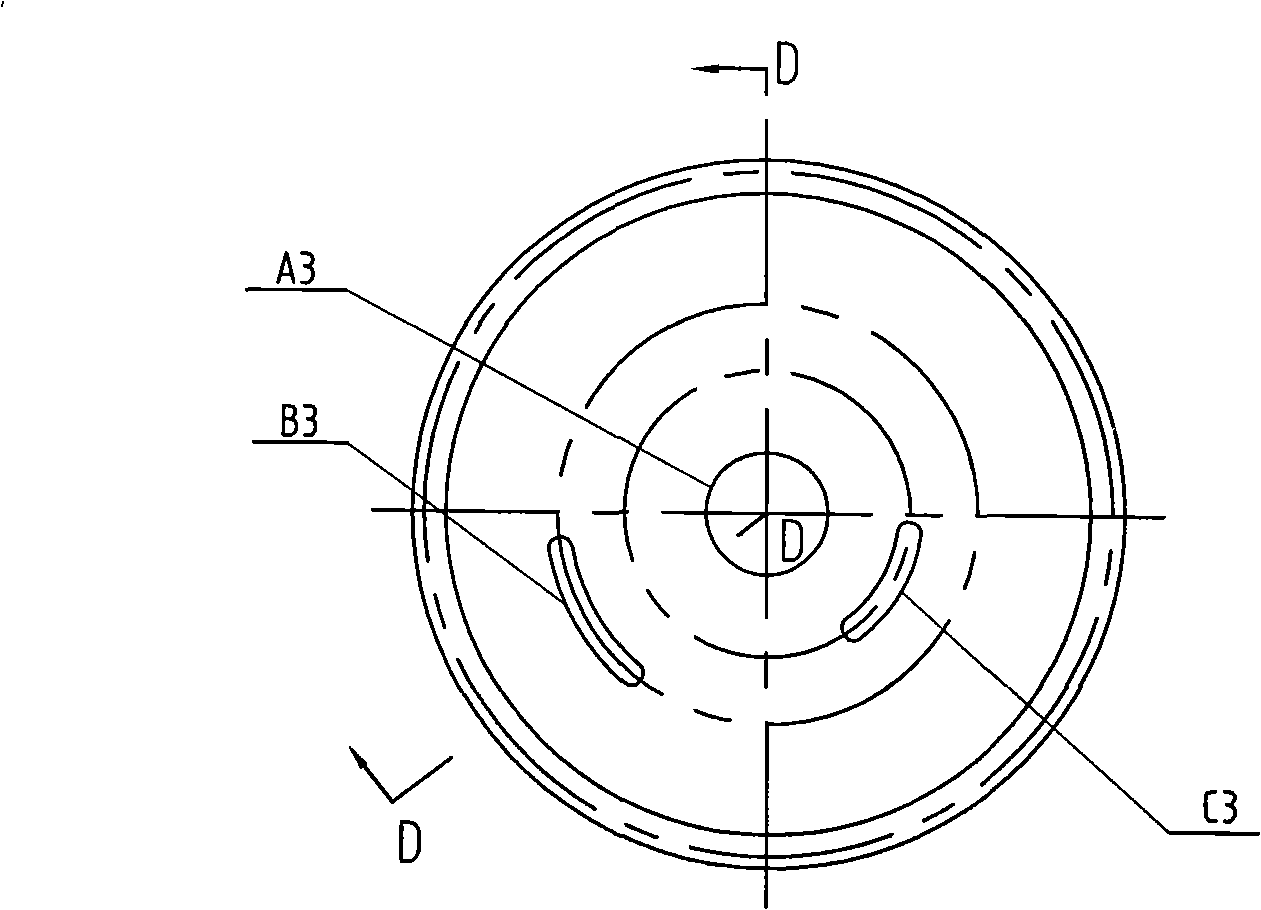

[0013] Specific implementation mode three: combination Figure 5 with Image 6 To illustrate this embodiment, the high-pressure passage A3, the load passage B3 and the oil return tank passage C3 on the rear distribution plate 8 of this embodiment are all composed of an axial straight passage 8-3 and an inclined passage 8-4, and the axial straight passage 8-3 is located on the small-diameter end face 8-1 of the rear distribution plate 8, which is convenient for outputting oil. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com