Vehicle gear mechanism

A technology for gears and vehicles, applied to mechanical equipment, components with teeth, belts/chains/gears, etc., can solve problems such as poor linearity of clutch cams, insufficient spring recovery, continuous gear delays, etc. Use the effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

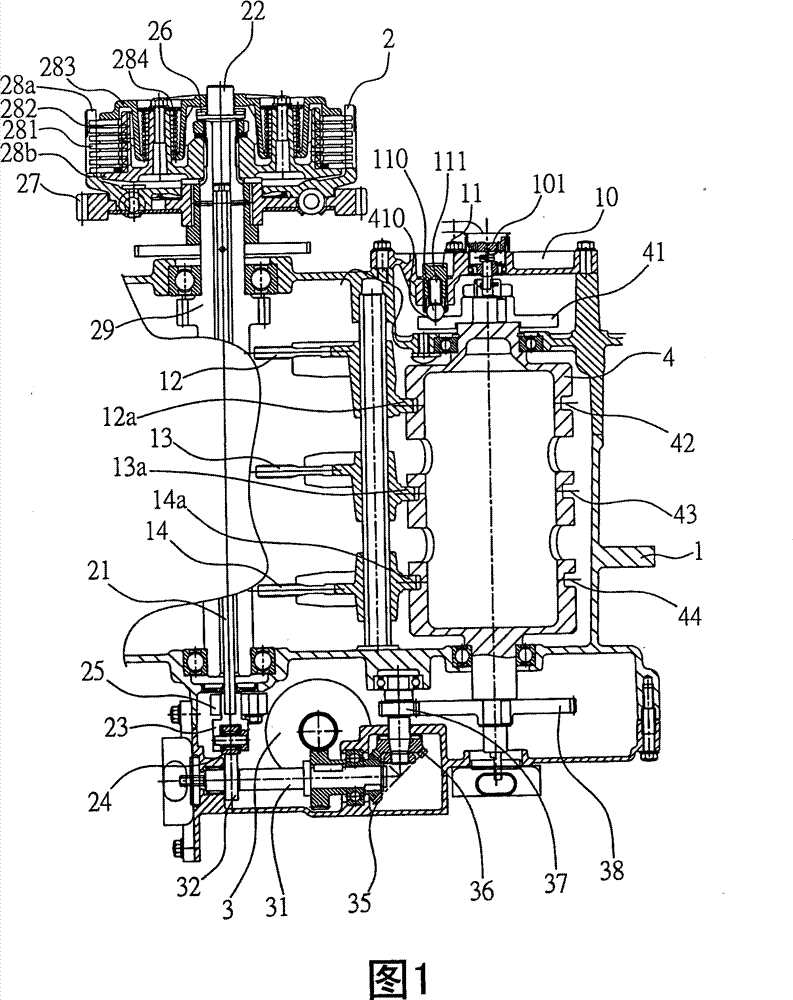

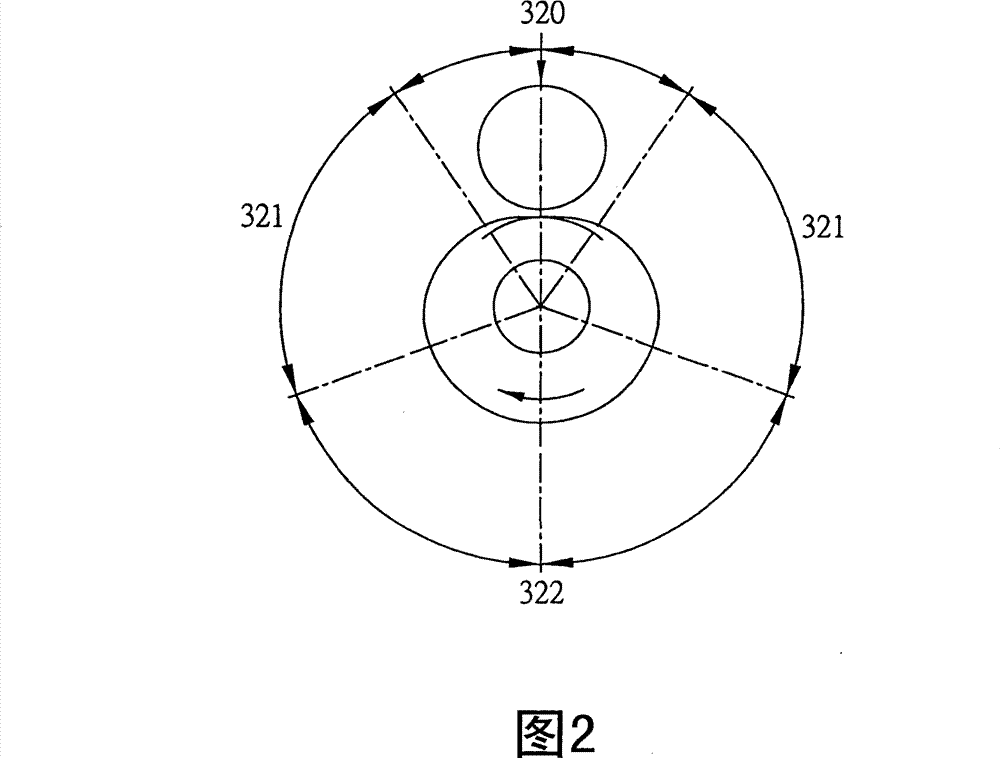

[0024] see figure 1 , the vehicle gear mechanism of the present invention is used to drive the clutch actuation of the clutch 2 of the gearbox 1 and the gear change of the gear drum 4. The clutch 2 also has clutch actuators 21 and 22 for actuating the clutch. The present invention The vehicle gear mechanism can include: a camshaft 31, linked to the gear drum 4; an actuating motor 3, driving the camshaft 31, so that the camshaft 31 rotates one revolution and simultaneously makes the gear drum 4 change a gear position; and a cam 32 , is connected to the camshaft 31 and rotates coaxially with it and is used to press the clutch actuator 21 of the clutch 2, and then the clutch actuator 21 presses the release of the clutch 2 arranged above the clutch actuator 21 The bearing actuator 22 and the clutch release bearing 26 arranged on the release bearing actuator 22 enable the clutch 2 to carry out clutch operation. The cam 32 can have a symmetrical profile, so that the camshaft 31 can ...

no. 2 example

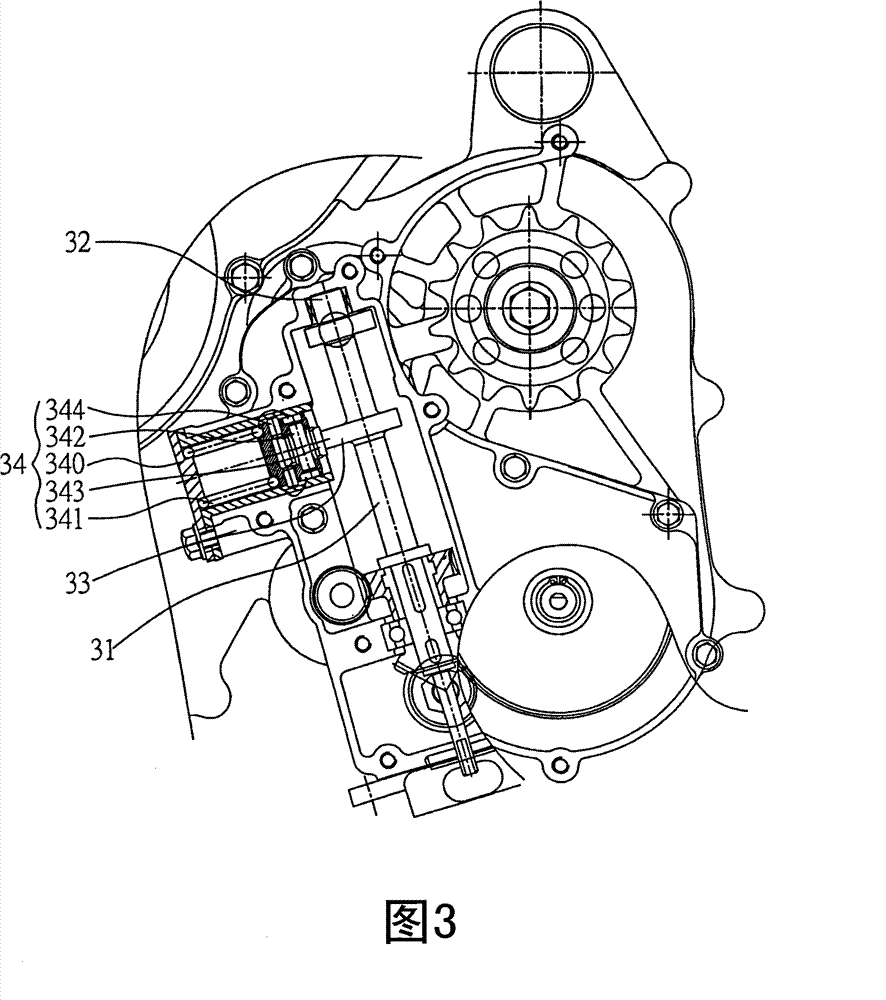

[0033] see image 3 , the present embodiment is substantially the same as the first embodiment, except that the camshaft 31 can be provided with a balance cam 33 coaxially rotating with the cam 32, and the balance cam 33 and the cam 32 have contours mutually and the balance cam 33 can be used to abut against an elastic device 34 connected to the casing of the gearbox 1 to obtain elastic support. The spring 341 in 340, the support seat 342 located at the end of the spring 341, the roller 343 that is axially connected to the support seat 342 and is in rolling contact with the balance cam 33, the circumference of the support seat 342 can be coated with a guide The housing 344, whereby the support seat 342 can only perform reciprocating linear motion, and then elastically supports the balance cam 33, so that the balance cam 33 can be used to counteract the effect of the cam 32 on the cam when the camshaft 31 rotates. Most of the moments of the shaft 31 are used to avoid damage ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com