Switchgear and method for manufacturing same

一种开关设备、真空容器的技术,应用在电开关、高压/大电流开关、高压空气断路器等方向,能够解决劳动和时间消耗等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

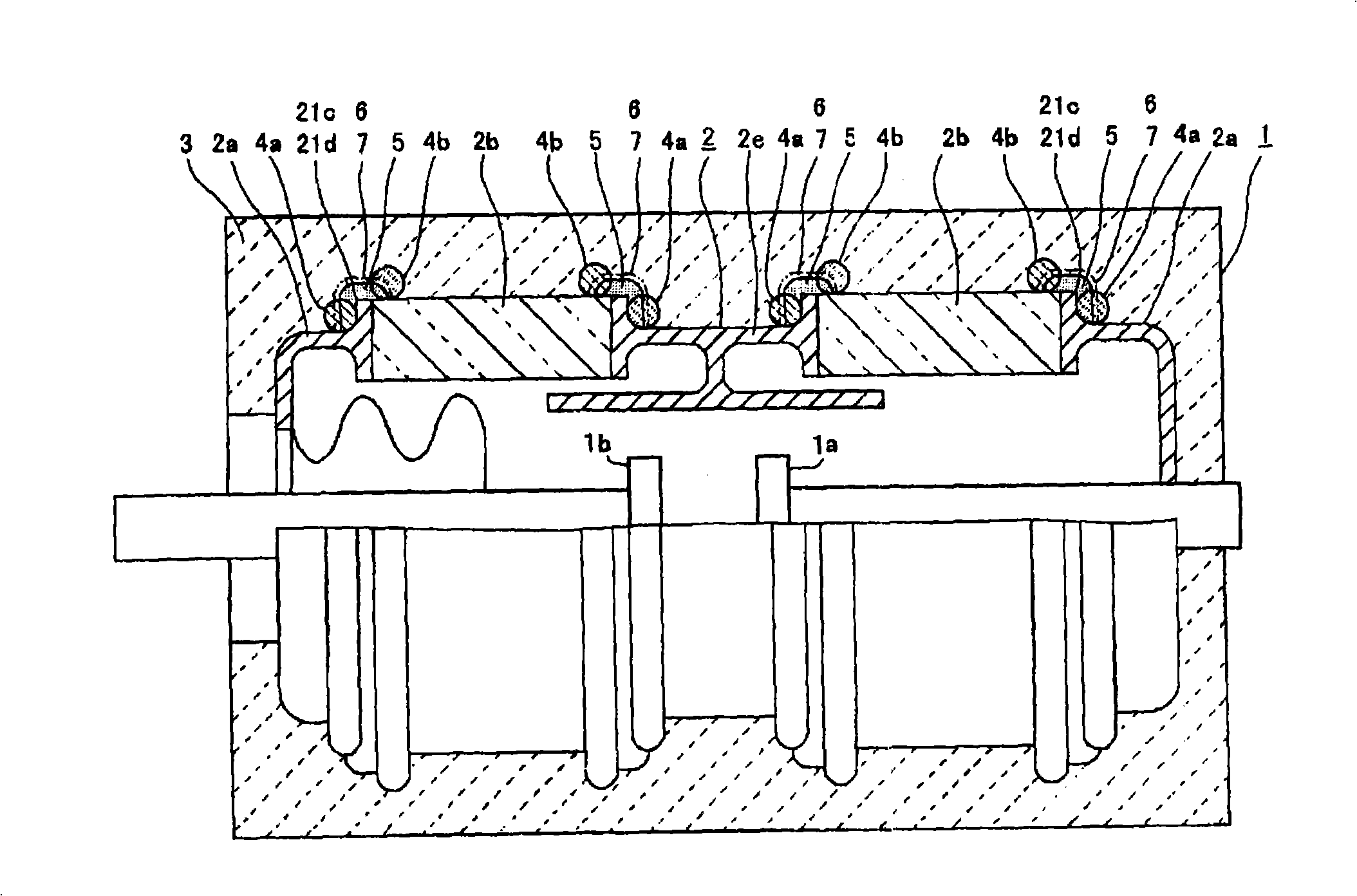

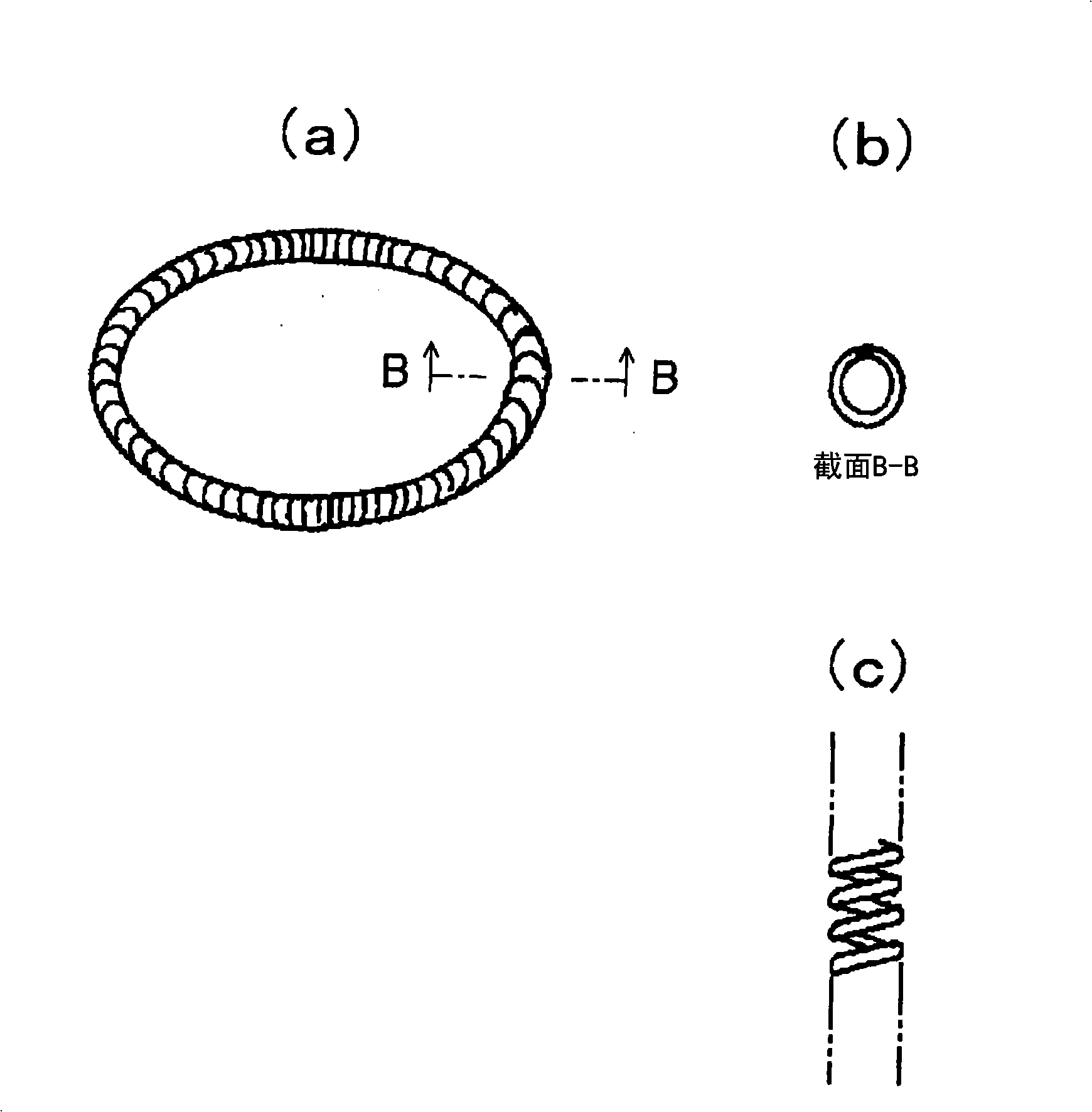

[0031] The following will combine figure 1 with figure 2 Embodiment 1 according to the present invention will be described. figure 1 is a partially cut sectional view showing the configuration of the switchgear including the vacuum valve in Embodiment 1. figure 2 Depicted are a perspective view, a sectional view, and a partially enlarged plan view showing the configuration of the shielding member in Embodiment 1. figure 2 (a) depicts a perspective view, figure 2 (b) depicts the figure 2 (a) The cross-sectional view taken along line B-B, figure 2 (c) depicts a partially enlarged plan view.

[0032] see figure 1 , the vacuum valve 1 is composed of a fixed electrode 1a and a movable electrode 1b, a vacuum container 2 and a resin mold plate 3, wherein the vacuum container 2 is composed of a metal flange 2a, a metal tube 2e and a ceramic insulating tube 2b, and the vacuum The container 2 incorporates the electrode 1 a and the electrode 1 b therein, and the resin mold 3...

Embodiment 2

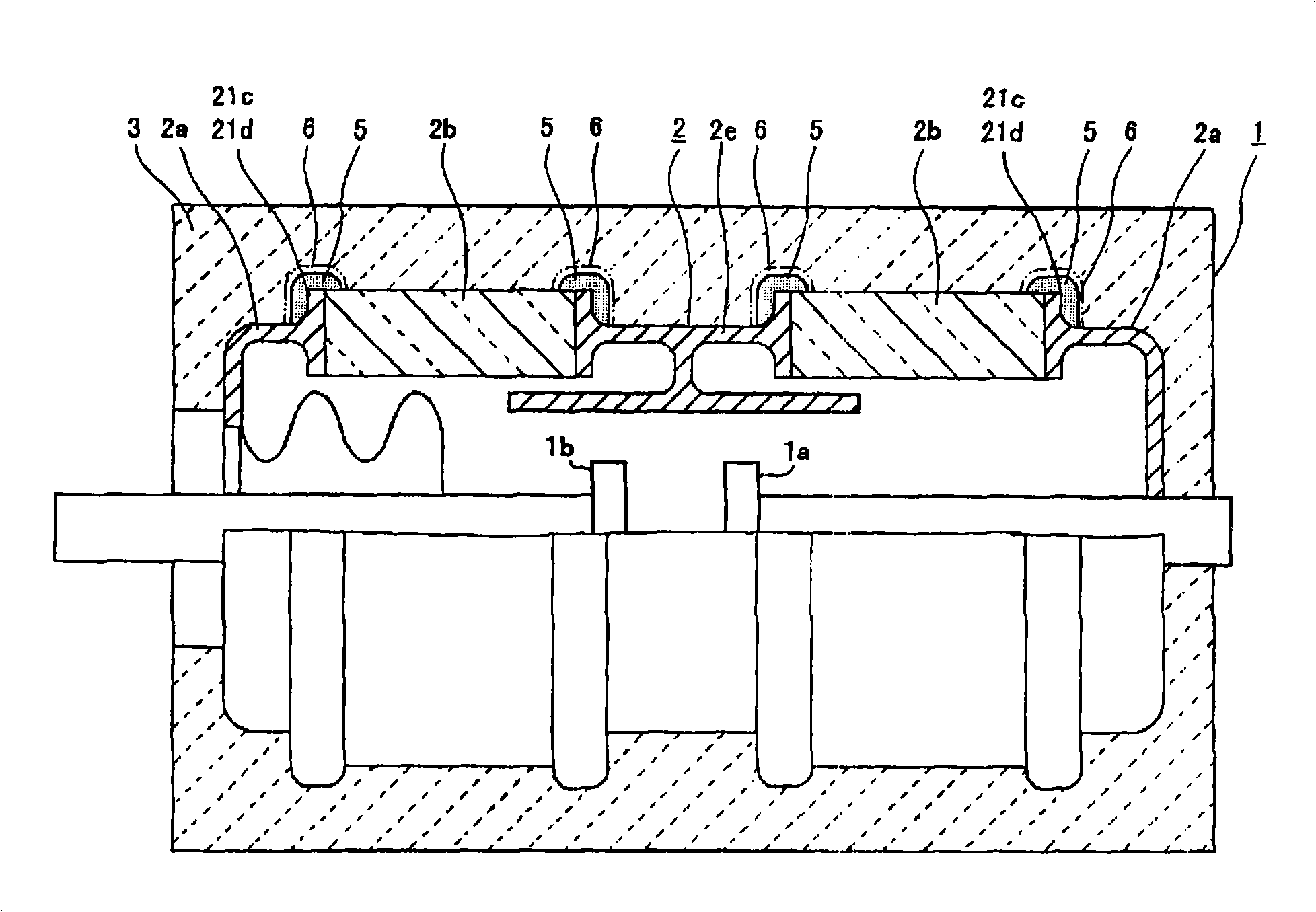

[0083] The following will combine image 3 Embodiment 2 according to the present invention will be described. image 3 is a partially cut sectional view showing the configuration of the switchgear including the vacuum valve 1 in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com