Nozzle mechanism, mounting head, and electronic component mounting equipment

A technology for electronic parts and mounting heads, applied in electrical components, electrical components, conveyor objects, etc., and can solve problems such as simplification limits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Before continuing the description of the present invention, the same reference numerals are given to the same parts in the drawings.

[0036] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

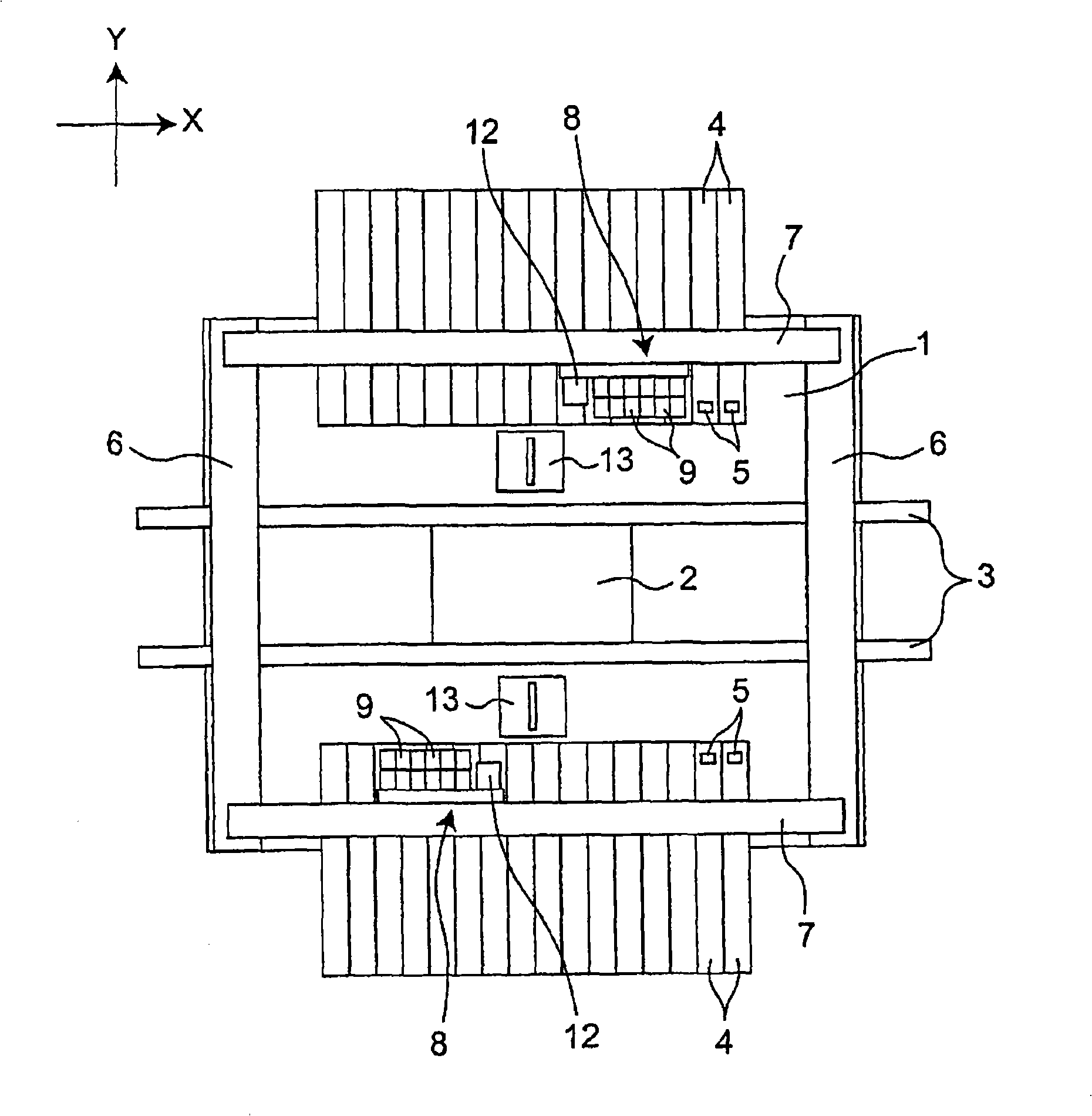

[0037] First, the whole structure of the electronic component mounting apparatus concerning embodiment of this invention is demonstrated. figure 1 A diagram showing the overall configuration of the electronic component mounting device according to the present embodiment, in figure 1 Among them, on the base 1 serving as a base of the electronic component mounting apparatus, a board conveying device 3 for conveying the board 2 is extended in the X direction. The board conveyance apparatus 3 has a function of sandwiching and holding the board|substrate 2, and functions as a board|substrate holding apparatus which holds the board|substrate 2 conveyed in the X direction at a predetermined position. In the present embodiment, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com