Filtering device and method for its manufacture

A technology of filtration and filter, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problem of rhythm reduction and achieve the effect of high color depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

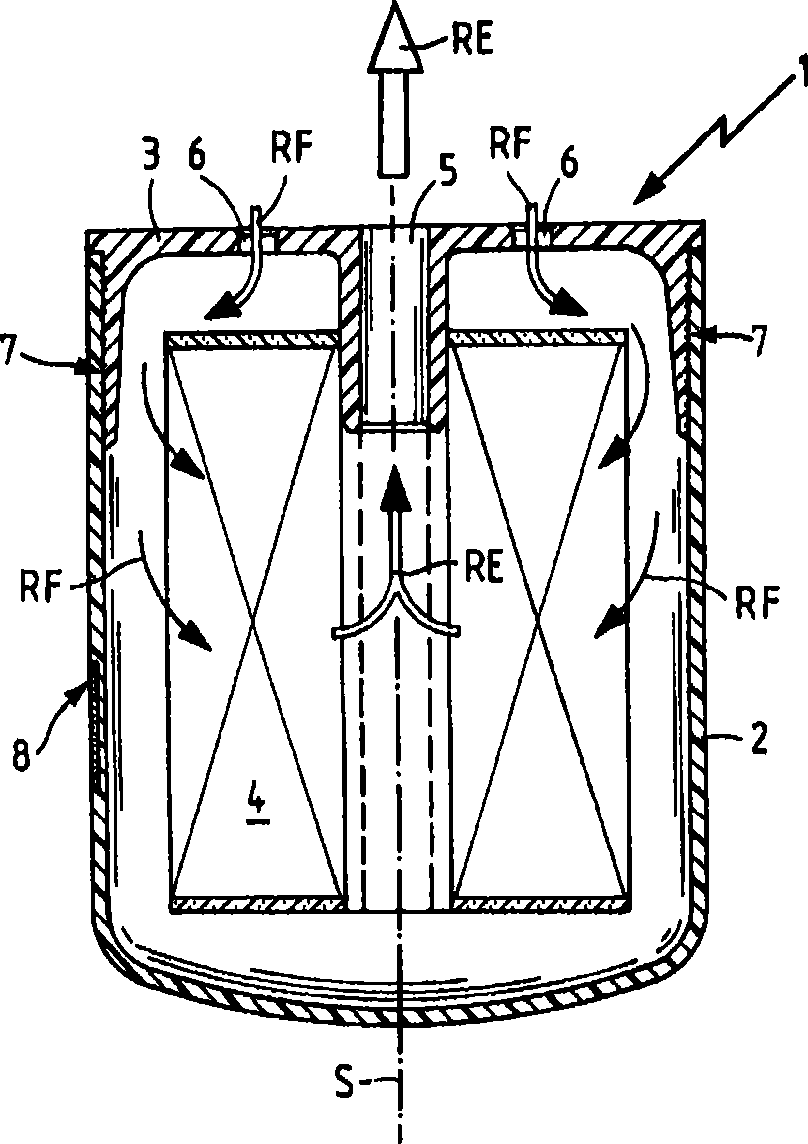

[0024] figure 1 A cross-sectional view of a filter device designed, for example, as an oil filter is shown. The filter device 1 has, for example, a cylindrical, open filter sump 2 in which a filter insert 4 is arranged.

[0025] The filter insert 4 can here be accordion-folded and have filter web material. In this case, the zigzag folded filter insert surrounds the axis of symmetry S, for example, and forms the interface between the raw fluid area and the cleaned fluid area in the filter sump 2 .

[0026] exist figure 1 In view from , the filter sump is closed upwards by the filter cover 3 . The filter cover 3 has a central opening 5 and further openings 6 through which raw fluid, for example motor oil, flows into the interior of the filter device 1 . This is shown by arrow RF. The oil to be filtered flows through the interface formed by the filter insert material and leaves the filter device 1 as cleaned fluid RE through the central opening 5 in the filter cover 3 . Flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com