Veneer lathe for cup mouth

A technology of rotary cutting machine and cup mouth, which is applied in the direction of metal processing machinery parts, turning equipment, large fixed members, etc. It can solve the problems of cup mouth deformation, processing quality impact, and product defect rate increase, and achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

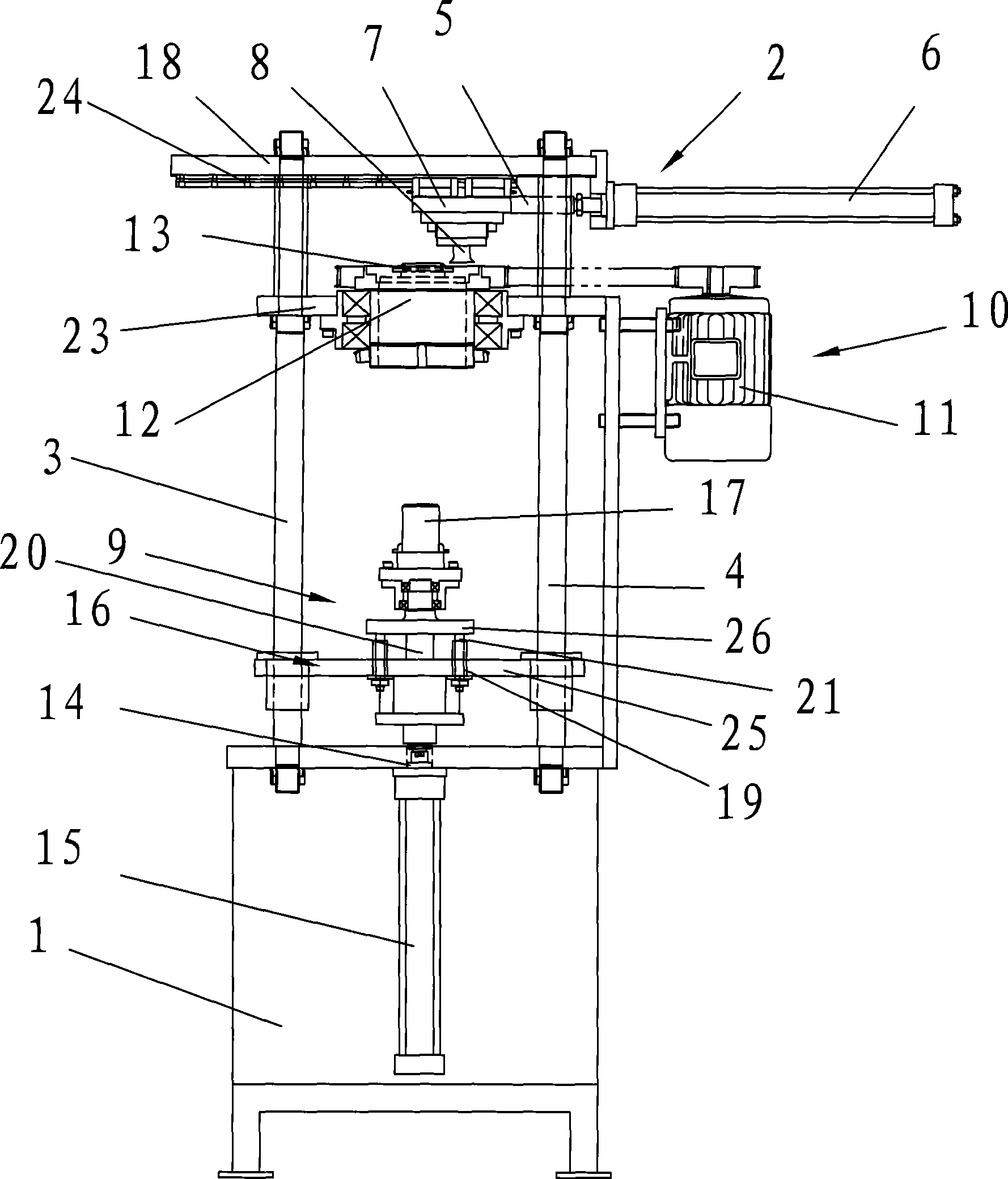

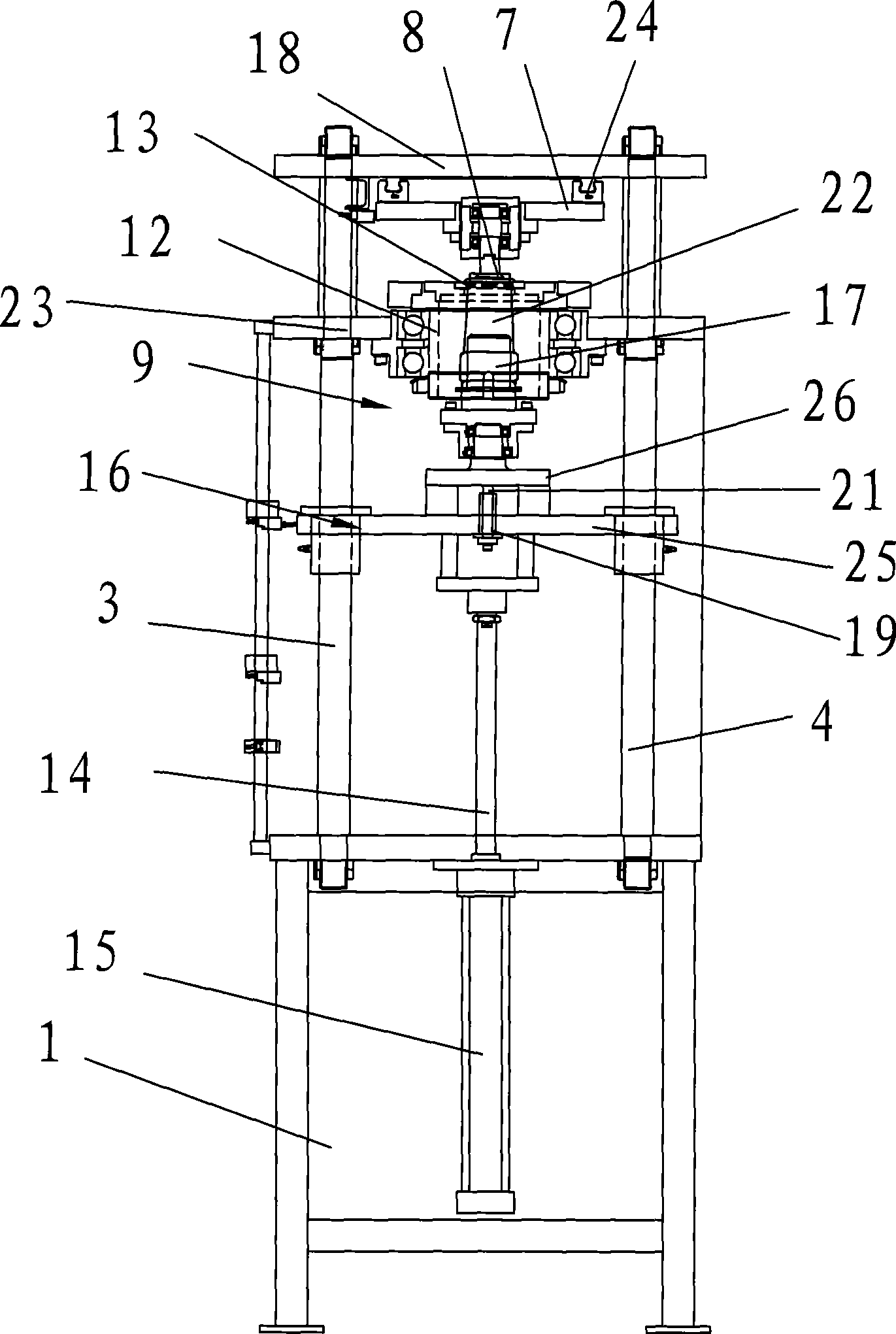

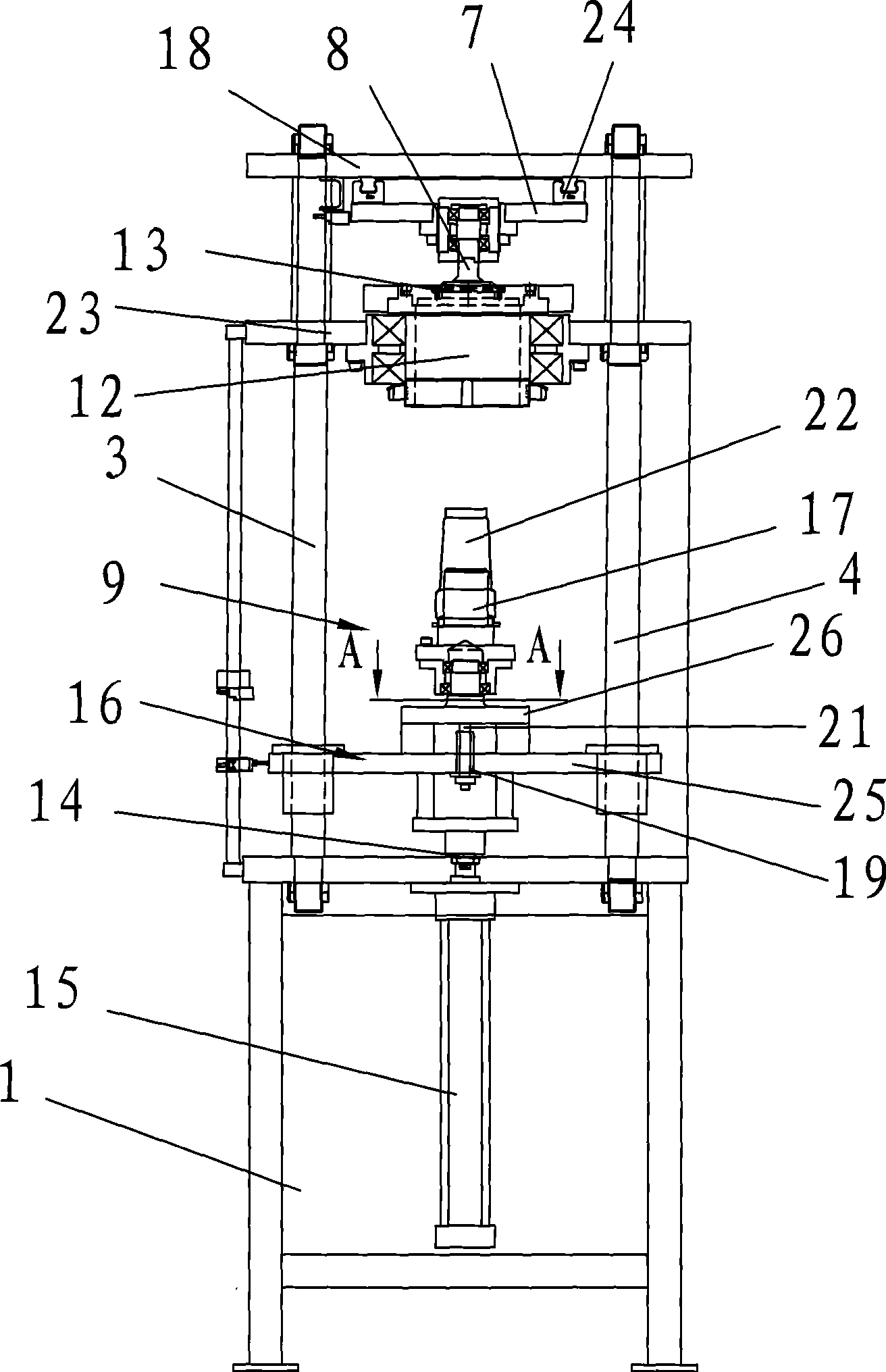

[0017] as attached figure 1 to attach image 3 As shown, a cup rotary cutter, it includes a base 1, a rotary cutter mechanism 2 arranged on the upper part of the base 1, the rotary cutter mechanism 2 includes movably connected to the The rotary cutter base 7 on the seat 1, the rotary cutter 8 arranged on the rotary cutter base 7, the cup rotation mechanism 10 and the cup positioning mechanism 9 are also arranged on the seat 1 , the cup rotation mechanism 10 is located between the rotary cutter mechanism 2 and the cup positioning mechanism 9, and the cup rotation mechanism 10 includes a The stator part 23 and the rotary mold 12 rotatably arranged in the stator part 23, the upper part of the rotary mold 12 has a profiling cavity 13 that is closely matched with the outer peripheral surface of the cup mouth; The cup positioning mechanism 9 comprises a positioning die base 16 that is liftably connected to the base 1, a cup positioning die 17 that is rotatably arranged on the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com