Recording medium and recording apparatus

一种记录介质、记录装置的技术,应用在打印装置、印刷、打字机等方向,能够解决成本高、不能提高记录位置精度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

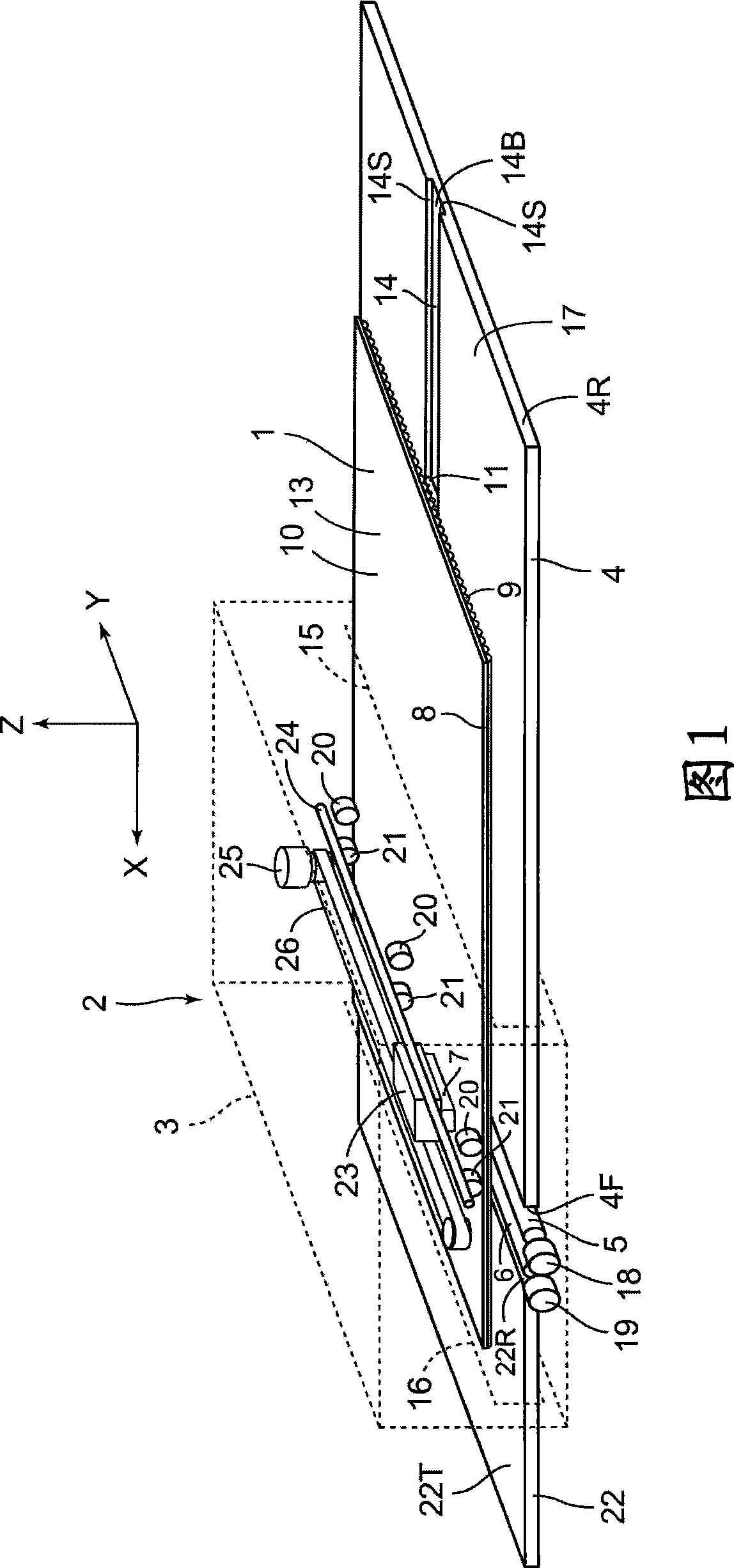

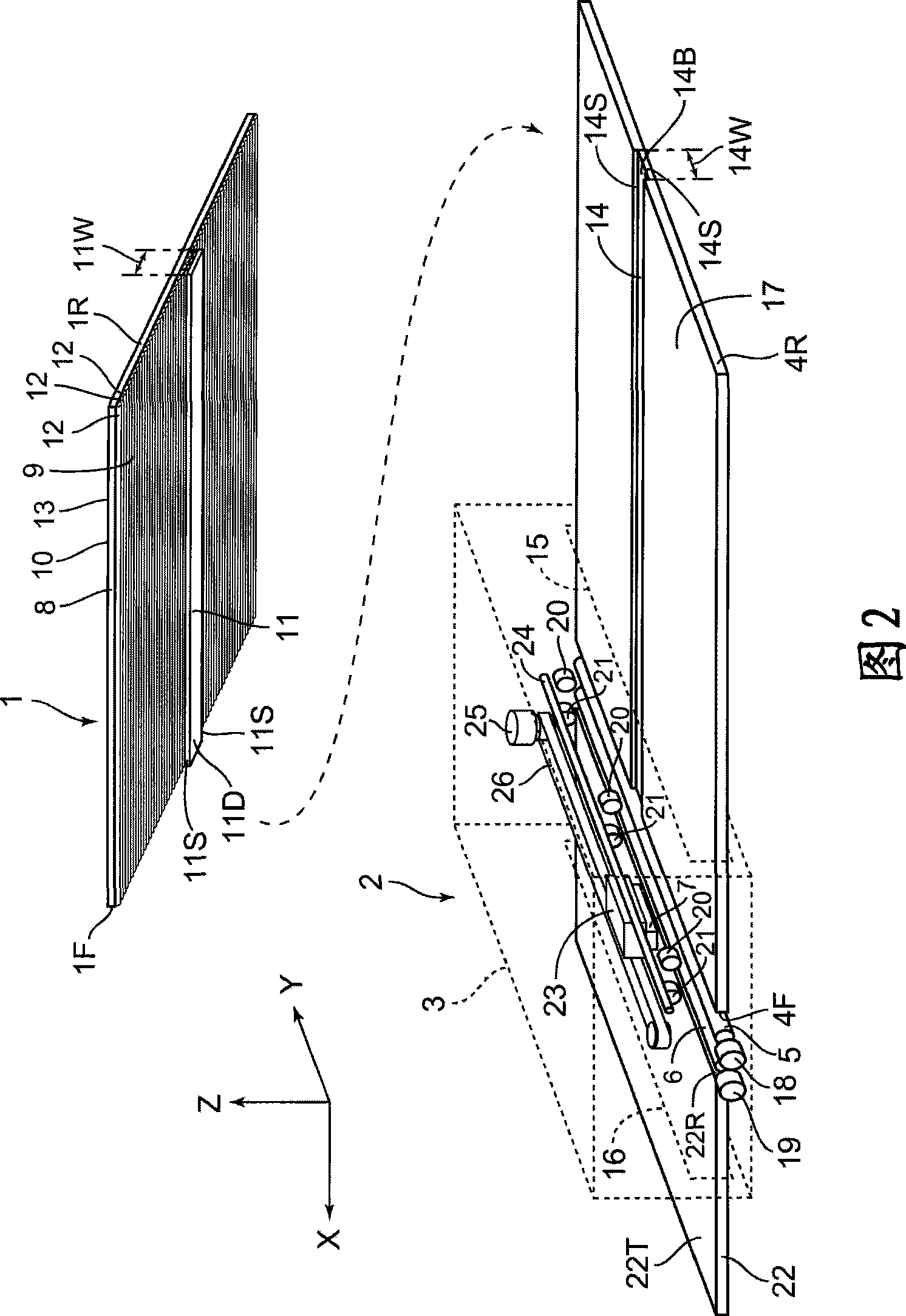

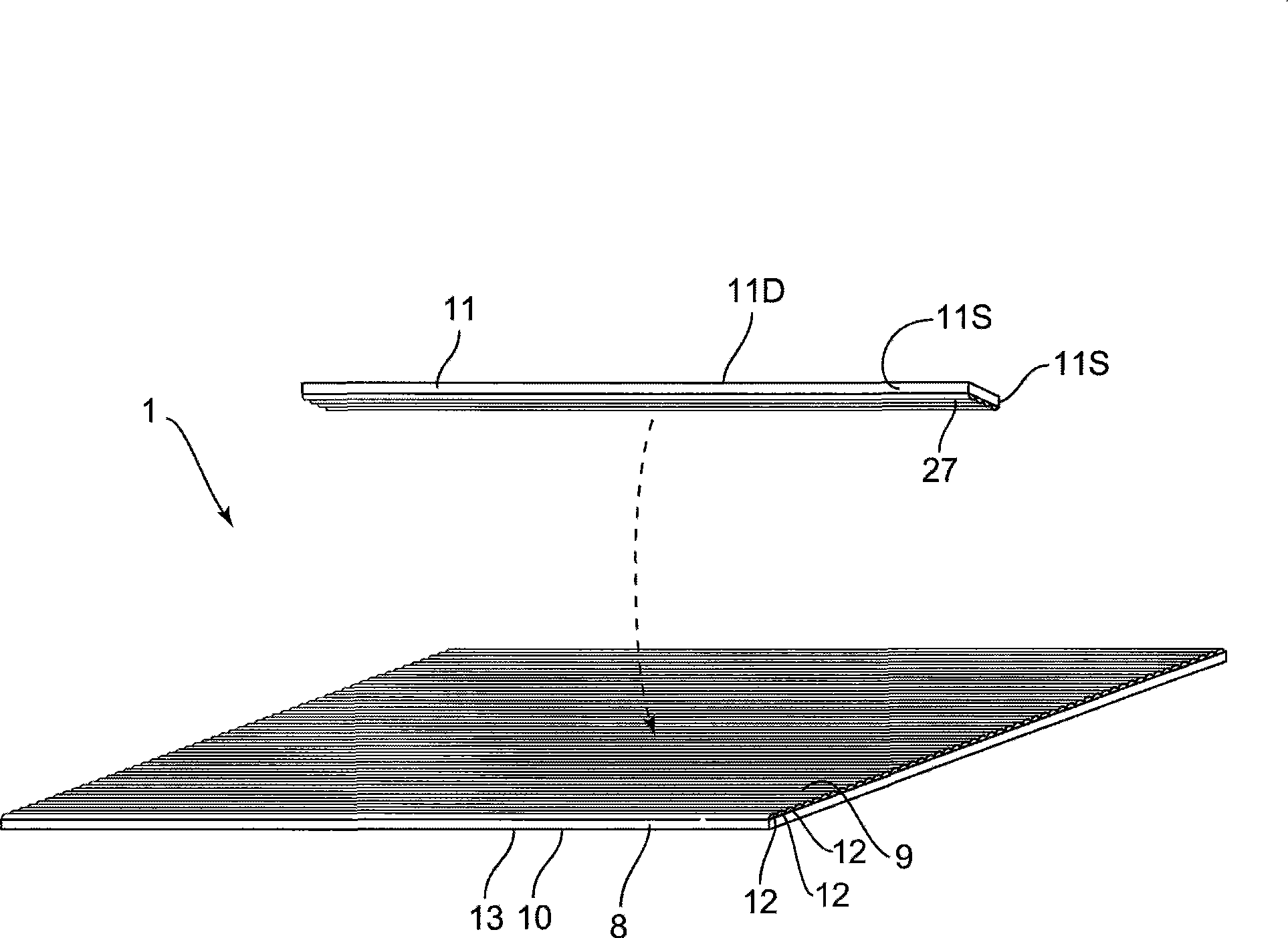

[0042] Below, refer to Figure 1 to image 3 , the lens sheet 1 and the recording device 2 according to the first embodiment of the present invention will be described.

[0043] 1 is a schematic configuration diagram showing a schematic configuration of a recording device 2 in a state where a lens sheet 1 as a recording medium is incorporated, and is a perspective view of the recording device 2 viewed from the rear. FIG. 2 is a diagram showing a state where the lens sheet 1 is detached from the recording device 2 shown in FIG. 1 . image 3 It is an exploded perspective view showing the structure of the lens sheet 1 . In addition, in the following description, in FIGS. 1 and 2 , the direction in which the lens sheet 1 travels, that is, the direction of arrow X is referred to as the front (front side), and the opposite direction is referred to as the rear (rear side). Furthermore, the direction of the arrow Y that is the right-hand direction from the rear to the front is referred...

Deformed example 4

[0083] (Modification 4 of lens sheet, Modification 2 of recording device)

[0084] FIG. 8 shows the structures of a lens sheet 70 as a fourth embodiment of the lens sheet 1 and a recording device 71 as a second modified example of the recording device 2 . In addition, about the same structure as demonstrated in the said 1st Embodiment, the same code|symbol is attached|subjected, and description is abbreviate|omitted.

[0085] As shown in FIG. 8 , the lens sheet 70 is provided with ridges 72 having the same structure as the ridges 11 on the left and right. Further, the sheet guide member 73 is provided with guide grooves 74 having the same structure as the above-described guide groove 14 on the left and right corresponding to the protruding line portion 72 . In addition, the recording device 71 has the same configuration as the above-described recording device 2 except for the configuration of the sheet guide member 73 . As described above, by guiding the lens sheet 70 at two...

no. 2 Embodiment approach

[0087] Below, refer to Figure 9 , the configuration of the lens sheet 80 according to the second embodiment of the present invention will be described. In addition, the same reference numerals are assigned to the same configurations as those described in the above-mentioned first embodiment and its modifications, and description thereof will be omitted.

[0088] The lens sheet 80 is provided with a recording area 81 and a convex portion installation area 82 located on the left and right outer sides of the recording area 81 . In this convex portion installation area 82, a lenticular lens 9 is provided in the same manner as the recording area 81, and is integrally formed with the recording area 81, but a perforated hole 83 as a cut-off structure is formed in the front-rear direction between the two. . Therefore, the convex-line portion installation region 82 can be cut out from the recording region 81 . Also, by forming a V-shaped groove instead of the perforation 83 , it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com