Guide wheel device for rail vehicle and method for adjusting position of guide wheel

A technology for a rail vehicle and a guide wheel, which is applied in the field of a guide wheel device for a rail vehicle and the position adjustment of the guide wheel, can solve the problems of abnormal friction of the guide wheel, stuck force of the guide wheel, uneven clearance, etc. performance, avoid wear and deformation, and high driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

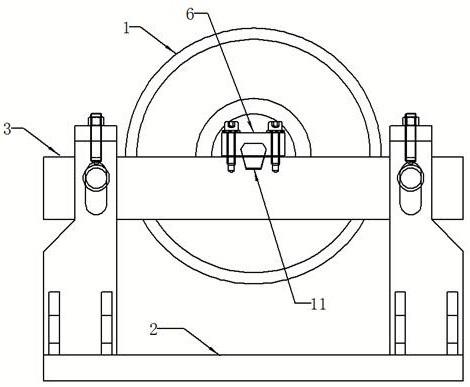

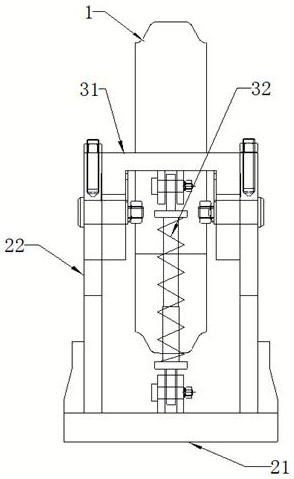

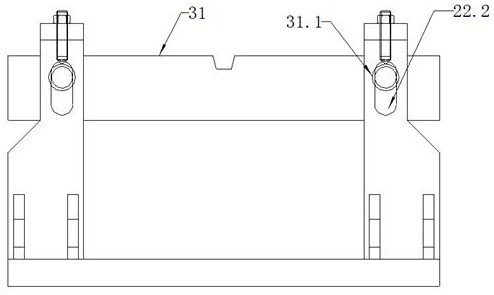

[0030] By the following Figure 1 ~ 5 Embodiments of the present invention will be described in detail.

[0031] The guide wheel device for the rail vehicle includes a guide wheel 1 that is guided to the vehicle body with the track, and the damper assembly 3 of the base 2 and the resilient support guide wheel 1 connected to the vehicle body, characterized in that the damping assembly 3 is characterized. In the front and rear sides of the guide wheel 1 in the orbit direction, the wheel shaft 11 of the guide wheel 1 is fixed, and the center position of the damper assembly 3 is fixed, the damper assembly 3 is elastically connected to the base 2, and the guide wheel 1 is reduced during the driving process. The elastic movement of the vibrating assembly 3 in the base is oriented with the track.

[0032] The guide wheel device according to the above-described rail vehicle is disposed in the prior art, and the vibration excitation in the guide wheel is disposed on both sides, and the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com