Electrical receptacle connector

A technology of electrical connectors and sockets, which is applied in the direction of connection and connection device parts, circuits, etc., can solve the problems that the tongue of the electrical connector is easy to wear and deform, repair or replace it together, and break, so as to improve the overall Structural strength, reduced maintenance costs, avoiding wear and deformation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only directions referring to the attached drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

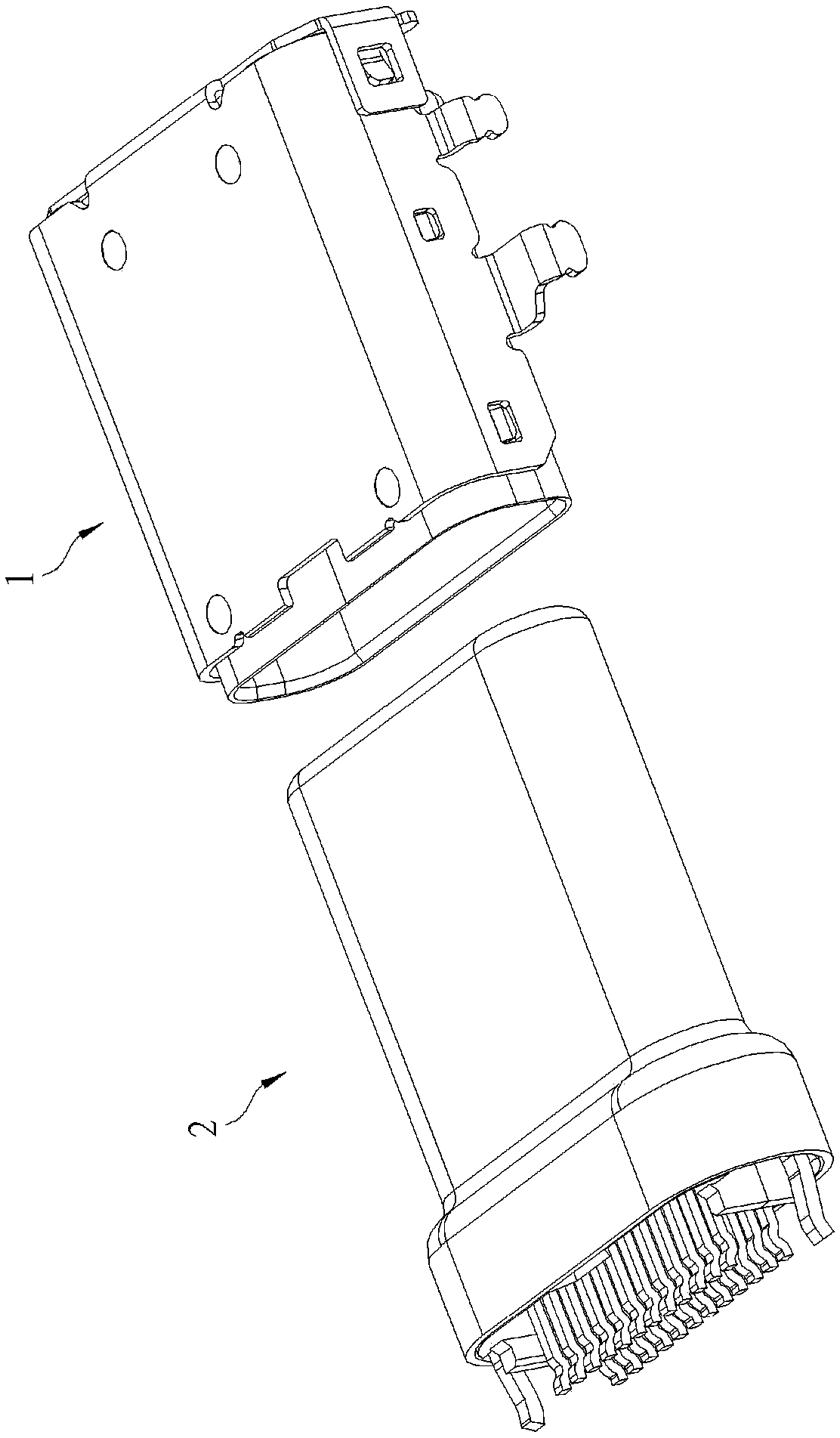

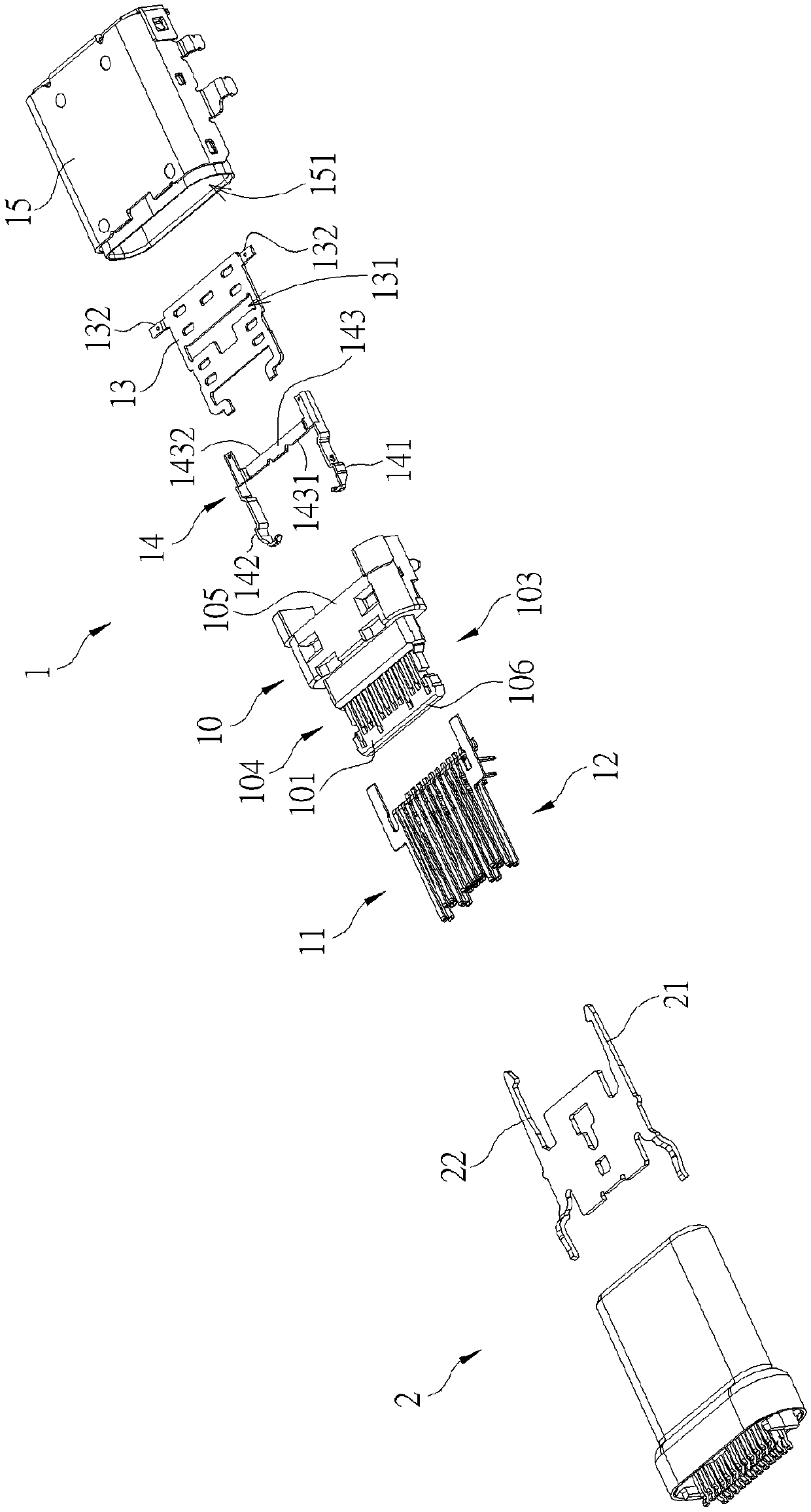

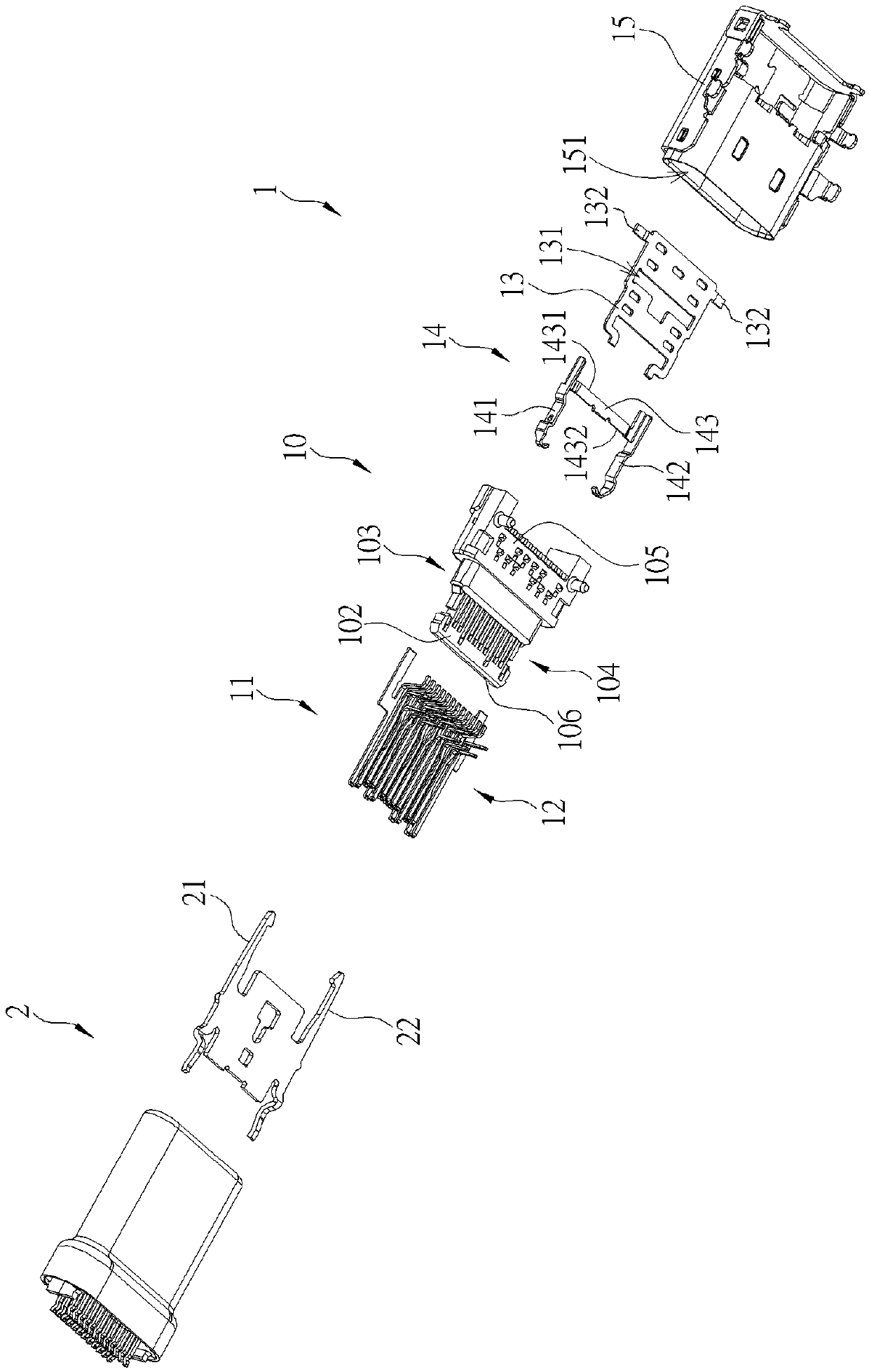

[0095] Please refer to Figures 1 to 3. Figure 1 is a schematic view of the appearance of a receptacle electrical connector 1 and a corresponding plug electrical connector 2 according to the first embodiment of the present invention. Figures 2 and 3 are diagrams of the present invention. An exploded view of some components of the socket electrical connector 1 and the corresponding plug electrical connector 2 in different viewing angles according to the first embodiment. As shown in Figures 1 to 3, the socket electrical connector 1 can be set on an electronic device (such as a computer host, a notebook computer or a mobile phone, etc.) A device supplies power or transmits a signal. The socket electrical connecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com