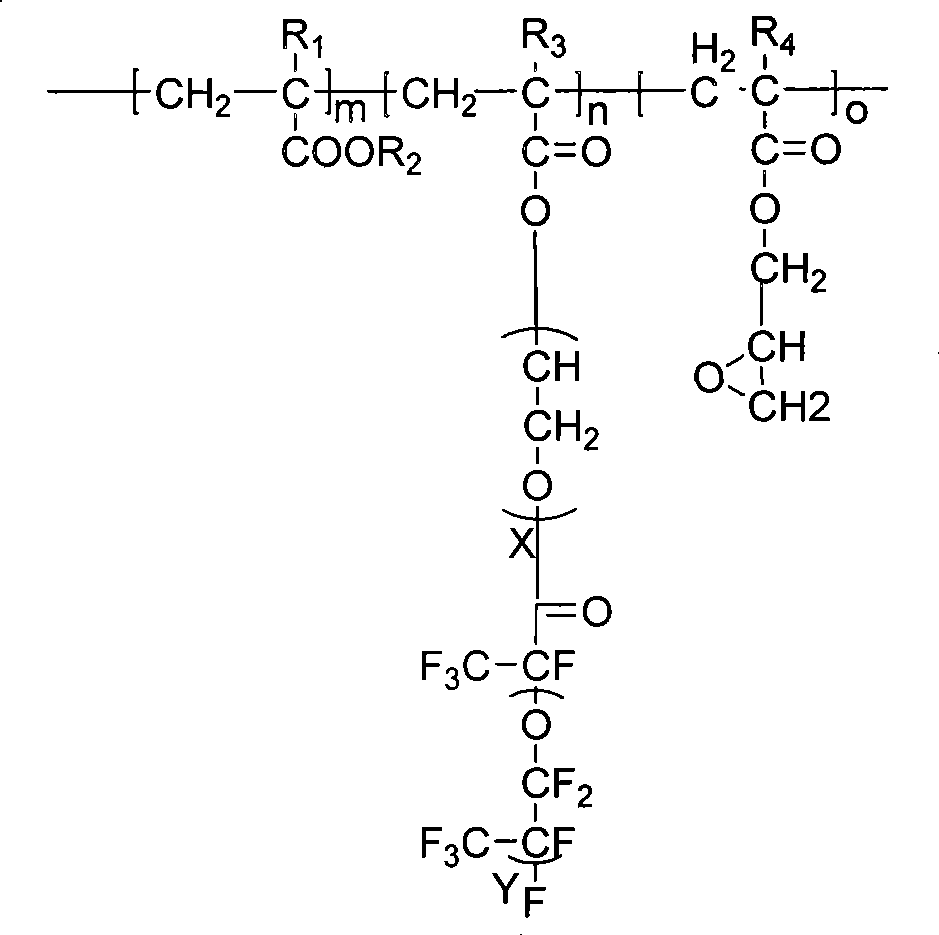

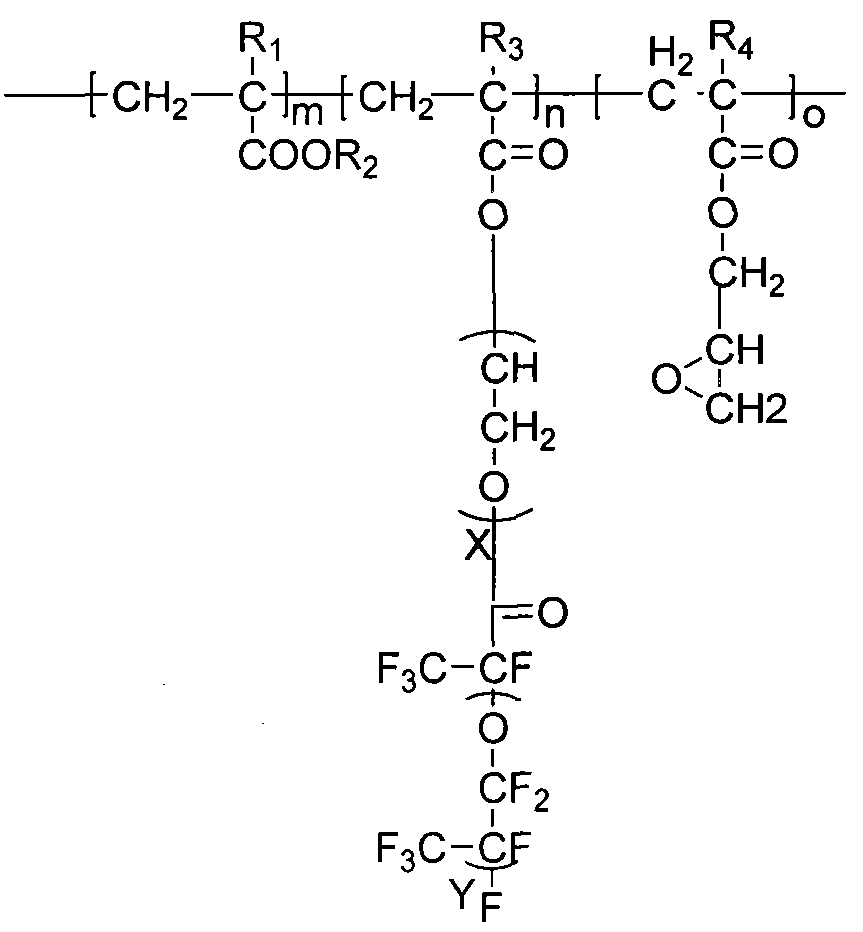

Acrylic resin containing amphipathic lateral chain, and preparation and use thereof

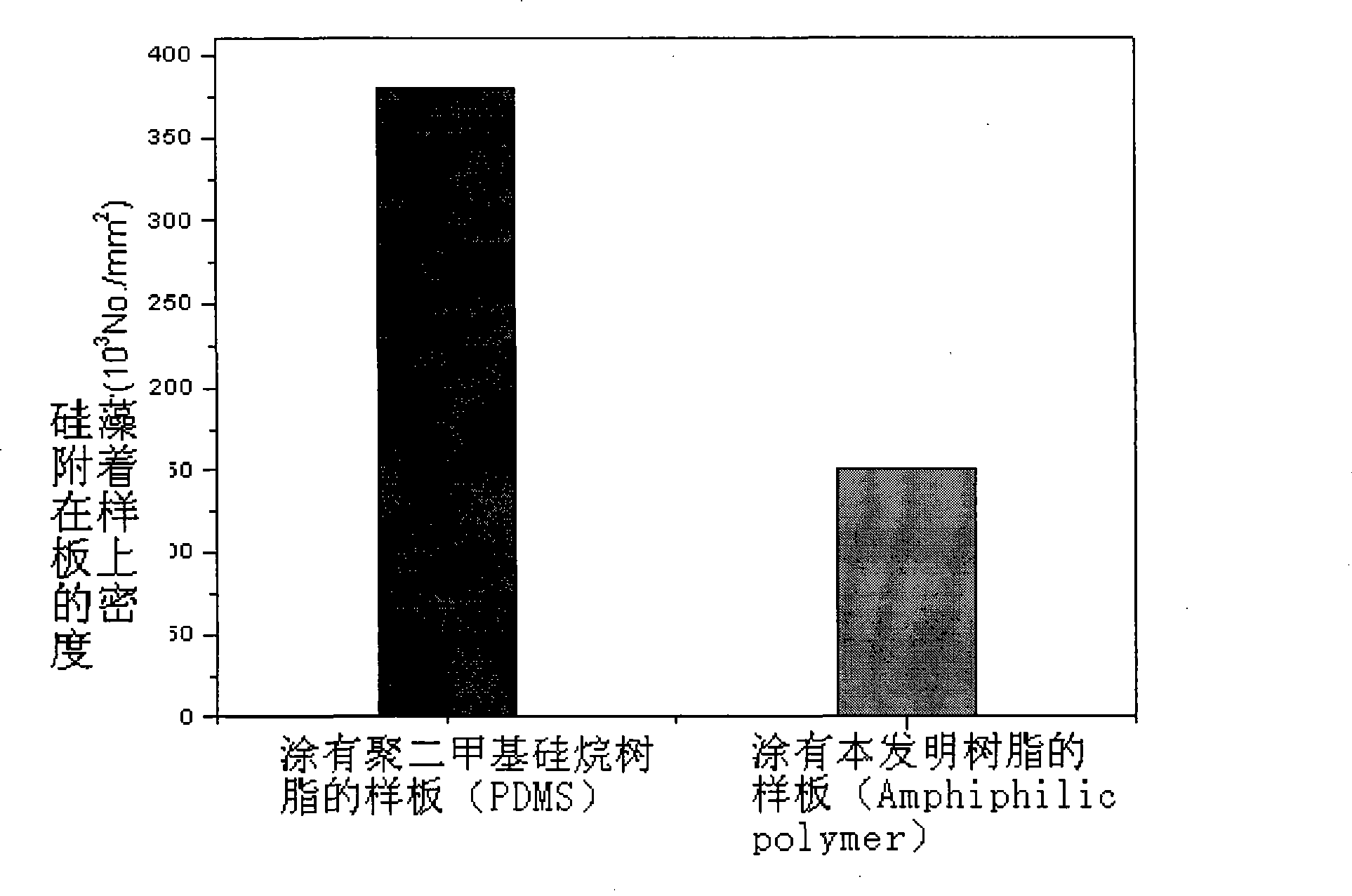

An acrylic resin and amphiphilic technology, which is applied in the field of acrylic resin containing amphiphilic side chains and its preparation, can solve the problems of large gaps, late development of antifouling coatings or paints, etc., and achieve good antifouling performance, good Effect of antifouling performance and eco-friendliness, good antifouling activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of acrylate derivatives

[0022] During preparation, under electromagnetic stirring in an oil bath, 300mL of dichloromethane, 67.9g of tetraethylene glycol and 15.2g of triethylamine were successively added to an absolutely anhydrous three-necked flask, and slowly added dropwise 15.6g of triethylamine under the protection of nitrogen. g methacryloyl chloride, heated to 25°C-40°C, stirred for 24 hours until a light yellow liquid appeared, then transferred the above reaction mixture to a one-necked bottle, and spin-dried to obtain a unilateral esterification product. Next, dissolve the esterification product in anhydrous dichloromethane, pour it into a dried three-neck bottle filled with triethylamine with a syringe, and slowly drop the acid fluoride containing perfluoropolyether chain under the protection of nitrogen. , heated up to -80°C to 25°C, stirred and reacted for several hours to obtain the acrylate derivative used in the present invention.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com