Antifouling and corrosion-resistant marine cement and preparation method thereof

A marine cement and corrosion-resistant technology, applied in the field of marine engineering building materials, can solve the problems of pollution, difficult to apply paint, difficult to prevent pollution and corrosion, and achieve long service life, prolong service life, improve anti-corrosion, etc. The effect of chloride ion osmosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

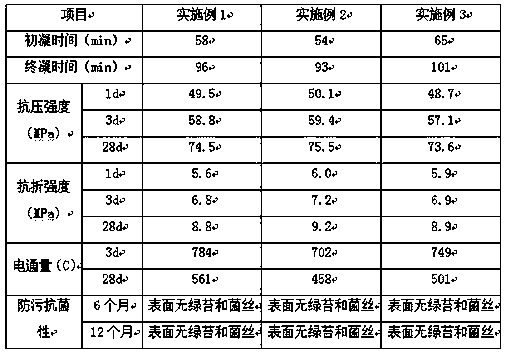

Examples

Embodiment 1

[0024] The anti-fouling and corrosion-resistant marine cement is made of the following parts by weight: 32 parts of marine portland cement clinker, 1 part of modified polycarboxylic acid water reducing agent, 5 parts of seaweed powder, 2 parts of garlic powder, acrylic acid 10 parts of ester, 1 part of silane coupling agent microcapsule, 30 parts of basalt crushed stone, 3 parts of nano-silica, 0.5 part of calcined attapulgite, and 10 parts of clinker sea sand.

[0025] The preparation method of the modified polycarboxylic acid water reducer: a mixed aqueous solution of prenol polyoxyethylene ether, (meth)acrylamide carboxybetaine and allyltrimethylammonium chloride is placed in a reactor At the same time, warm up to 32℃, add hydrogen peroxide; at the same time, slowly add the aqueous solution of acrylic acid for 3 hours and the mixed solution of 2-mercaptopropanol and ferrous sulfate for 3 hours. After the addition is completed, keep it for 1 hour; after the reaction, it is coole...

Embodiment 2

[0033] The anti-fouling and corrosion-resistant marine cement is made of the following parts by weight: 40 parts of marine portland cement clinker, 1.2 parts of modified polycarboxylate water reducing agent, 10 parts of seaweed powder, 4 parts of garlic powder, acrylic acid 12 parts of ester, 3 parts of silane coupling agent microcapsules, 35 parts of basalt crushed stone, 4 parts of nano silica, 0.8 parts of calcined attapulgite, and 12 parts of clinker sea sand.

[0034] The preparation method of the modified polycarboxylic acid water reducing agent: placing a mixed aqueous solution of isopentenol polyoxyethylene ether, (meth)acrylamide carboxybetaine and allyltrimethylammonium chloride in a reactor At the same time, the temperature was raised to 35°C, and hydrogen peroxide was added; at the same time, the aqueous solution of acrylic acid for 2.5 hours and the mixed solution of 2-mercaptopropanol and ferrous sulfate were slowly added for 2.5 hours. After the addition was complet...

Embodiment 3

[0042] The anti-fouling and corrosion resistant marine cement is made of the following parts by weight: 48 parts of marine portland cement clinker, 1.5 parts of modified polycarboxylic acid water reducing agent, 15 parts of seaweed powder, 6 parts of garlic powder, acrylic acid 15 parts of ester, 5 parts of silane coupling agent microcapsules, 40 parts of basalt crushed stone, 5 parts of nano silica, 1 part of calcined attapulgite, and 15 parts of clinker sea sand.

[0043] The preparation method of the modified polycarboxylic acid water reducing agent: placing a mixed aqueous solution of isopentenol polyoxyethylene ether, (meth)acrylamide carboxybetaine and allyltrimethylammonium chloride in a reactor At the same time, warm up to 38℃, add hydrogen peroxide; at the same time, slowly add the aqueous solution of acrylic acid for 2h and the mixed solution of 2-mercaptopropanol and ferrous sulfate for 2h. After the dripping is completed, keep it for 3h; after the reaction, it is coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com