A kind of preparation method of organosilicon marine antifouling coating

A marine antifouling and silicone technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of reduced heat resistance, toxicity, and lower curing temperature, and achieve improved antifouling performance, good antifouling activity, good growth inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

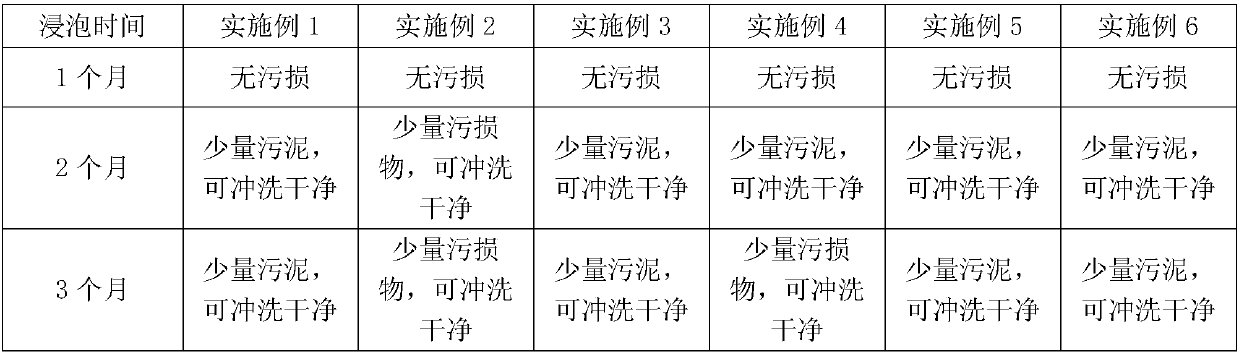

Examples

Embodiment 1

[0028] Follow these steps to prepare a silicone marine antifouling coating:

[0029] (1) Laver is placed in a blast drying oven to be dried at 60°C, then pulverized with a pulverizer and sieved to obtain laver powder, the laver powder is added to distilled water, the weight ratio of laver powder and distilled water is 1:10, room temperature Soak for 10 hours, put it into a volatile oil extractor for steam distillation for 4 hours to obtain volatile oil, and place the volatile oil on a rotary evaporator for rotary evaporation and concentration to obtain a paste-like seaweed extract for subsequent use;

[0030] (2) After mixing dimethyl silicone oil, PVP, EMA, and BA uniformly, add initiator TBPO, and after stirring uniformly, a monomer solution is obtained, and dichloromethane is added into the reactor. The weight ratio of TBPO and methylene chloride is 20:40:20:25:2:90, heated to 110 ° C, the monomer solution is added dropwise to the reactor within 4 hours under stirring condi...

Embodiment 2

[0034] Follow these steps to prepare a silicone marine antifouling coating:

[0035] (1) Laver is placed in a blast drying oven to be dried at 60°C, then pulverized with a pulverizer and sieved to obtain laver powder, the laver powder is added to distilled water, the weight ratio of laver powder and distilled water is 1:10, room temperature Soak for 10 hours, put it into a volatile oil extractor for steam distillation for 4 hours to obtain volatile oil, and place the volatile oil on a rotary evaporator for rotary evaporation and concentration to obtain a paste-like seaweed extract for subsequent use;

[0036] (2) After mixing dimethyl silicone oil, PVP, EMA, and BA uniformly, add initiator TBPO, and after stirring uniformly, a monomer solution is obtained, and dichloromethane is added into the reactor. The weight ratio of TBPO and methylene chloride is 20:40:20:25:2:90, heated to 110 ° C, the monomer solution is added dropwise to the reactor within 4 hours under stirring condi...

Embodiment 3

[0040] Follow these steps to prepare a silicone marine antifouling coating:

[0041] (1) Laver is placed in a blast drying oven to be dried at 60°C, then pulverized with a pulverizer and sieved to obtain laver powder, the laver powder is added to distilled water, the weight ratio of laver powder and distilled water is 1:10, room temperature Soak for 10 hours, put it into a volatile oil extractor for steam distillation for 4 hours to obtain volatile oil, and place the volatile oil on a rotary evaporator for rotary evaporation and concentration to obtain a paste-like seaweed extract for subsequent use;

[0042] (2) After mixing dimethyl silicone oil, PVP, EMA, and BA uniformly, add initiator TBPO, and after stirring uniformly, a monomer solution is obtained, and dichloromethane is added into the reactor. The weight ratio of TBPO and methylene chloride is 20:40:20:25:2:90, heated to 110 ° C, the monomer solution is added dropwise to the reactor within 4 hours under stirring condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com