Preparation method of marine antifouling and anticorrosive coating

An anti-corrosion coating and marine anti-fouling technology, applied in the field of coatings, can solve the problems of poor anti-fouling durability, water environment damage, and poor anti-fouling performance, and achieve the effects of long-lasting effect, good anti-fouling activity, and improved anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

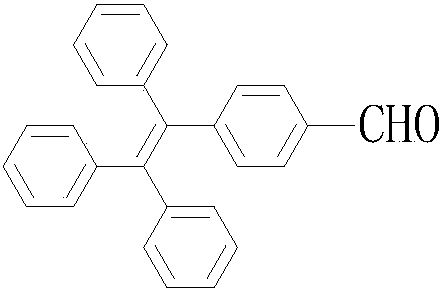

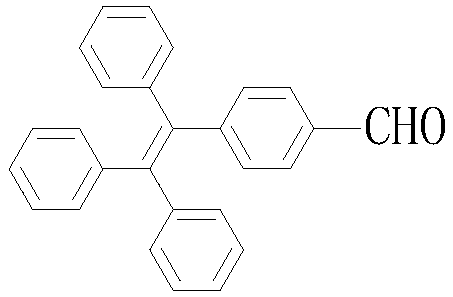

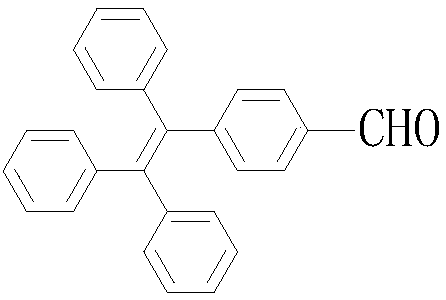

[0022] The preparation method of the piezoluminescent material of the present invention is as follows: dissolve bromotriphenylethylene and 4-formylphenylboronic acid in toluene, add tetrabutylammonium bromide and potassium carbonate aqueous solution; (Triphenylphosphine)palladium, heated to 90°C for 24h; after the reaction, pour the reaction solution cooled to room temperature into water, and extract with ethyl acetate; after the organic layer was dried with anhydrous sodium sulfate, the solvent was evaporated , using silica gel column chromatography for purification, using n-hexane and dichloromethane mixed solvent as the eluent to leaching, the obtained white product is the piezoluminescence material, and the yield is 97%.

[0023] The general structural formula of the piezoluminescence material is:

[0024]

Embodiment 1

[0026] 1) Preparation of anti-fouling and anti-corrosion enhanced emulsion:

[0027] Take by weight 30 parts of piezoluminescent material, 10 parts of photocatalyst material and 40 parts of acrylic zinc resin; under the rotating speed of 300 rpm, add piezoluminescent material, photocatalyst material and acrylic zinc resin together in the mixer, stir Preliminary mixing for 5 minutes; then adjust the rotation speed to above 1200 rpm, and stir for 10 minutes to obtain an antifouling and anticorrosion enhanced emulsion;

[0028] 2) Preparation of environment-friendly anti-fouling and anti-corrosion coating:

[0029] ①Put seaweed and garlic with a weight ratio of 1:0.4 in a blast drying oven and dry at 45°C, then pulverize with a pulverizer and sieve to obtain a mixed powder of garlic and seaweed, and add the mixed powder to distilled water , soaked at a constant temperature at 40°C for 5 hours; then put the whole into a volatile oil extractor and steam distill for 4 hours to obta...

Embodiment 2

[0033] 1) Preparation of anti-fouling and anti-corrosion enhanced emulsion:

[0034] Take by weight 20 parts of piezoluminescent material, 15 parts of photocatalyst material and 30 parts of zinc acrylic resin; under the rotating speed of 300 rpm, add piezoluminescent material, photocatalyst material and zinc acrylic resin into the mixer together, stir Preliminary mixing for 5 minutes; then adjust the rotation speed to above 1200 rpm, and stir for 10 minutes to obtain an antifouling and anticorrosion enhanced emulsion;

[0035] 2) Preparation of environment-friendly anti-fouling and anti-corrosion coating:

[0036] ①Put seaweed and garlic with a weight ratio of 1:0.4 in a blast drying oven and dry at 45°C, then pulverize with a pulverizer and sieve to obtain a mixed powder of garlic and seaweed, and add the mixed powder to distilled water , soaked at a constant temperature at 40°C for 5 hours; then put the whole into a volatile oil extractor and steam distill for 4 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com