Array type metal cup-shaped thin wall structure energy absorber

A thin-walled structure and metal cup technology, which is applied to elastic shock absorbers, railway car body parts, bumpers, etc., can solve problems such as large impact force, and achieve the effects of stable impact force, good protection, and high working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

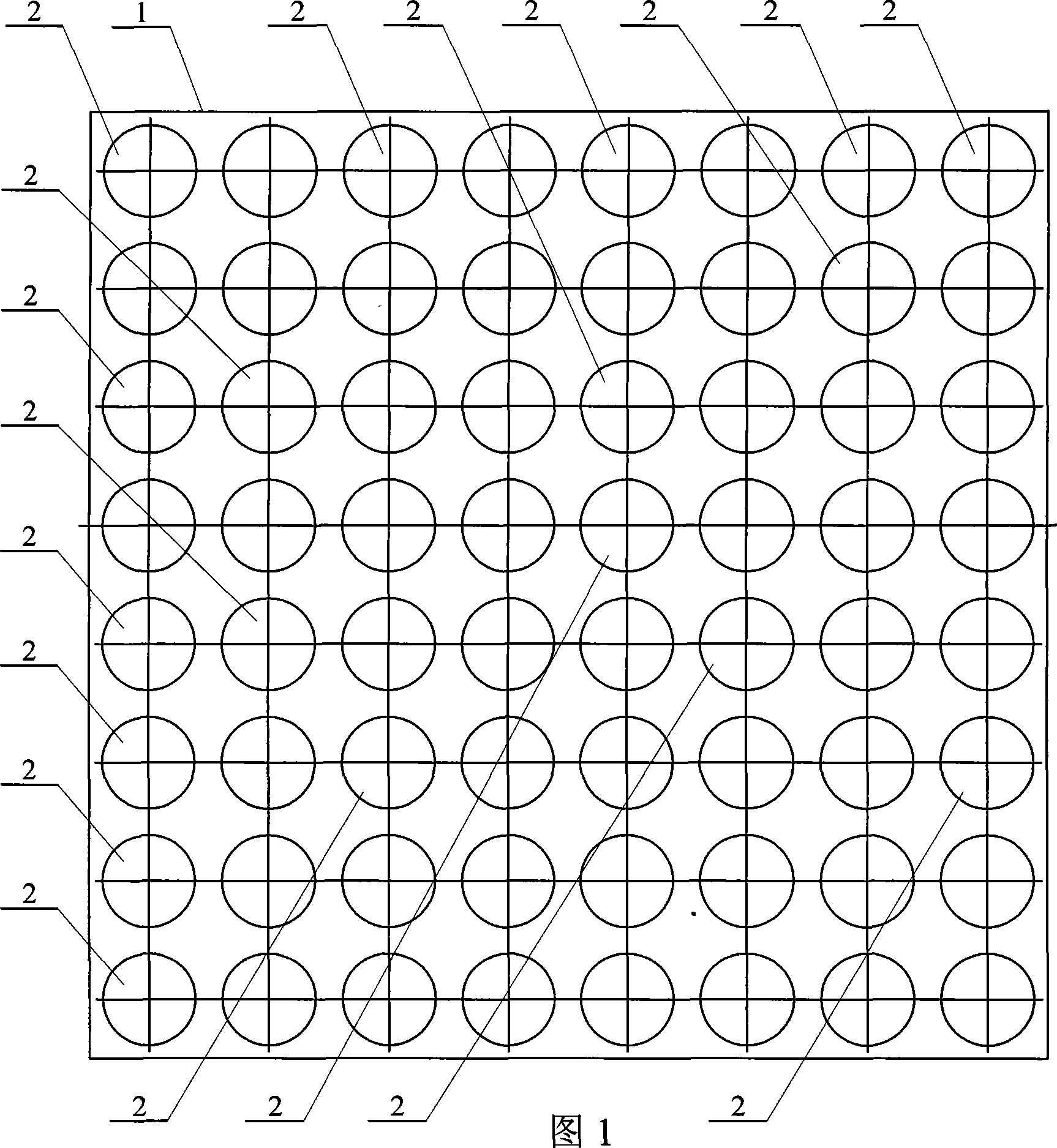

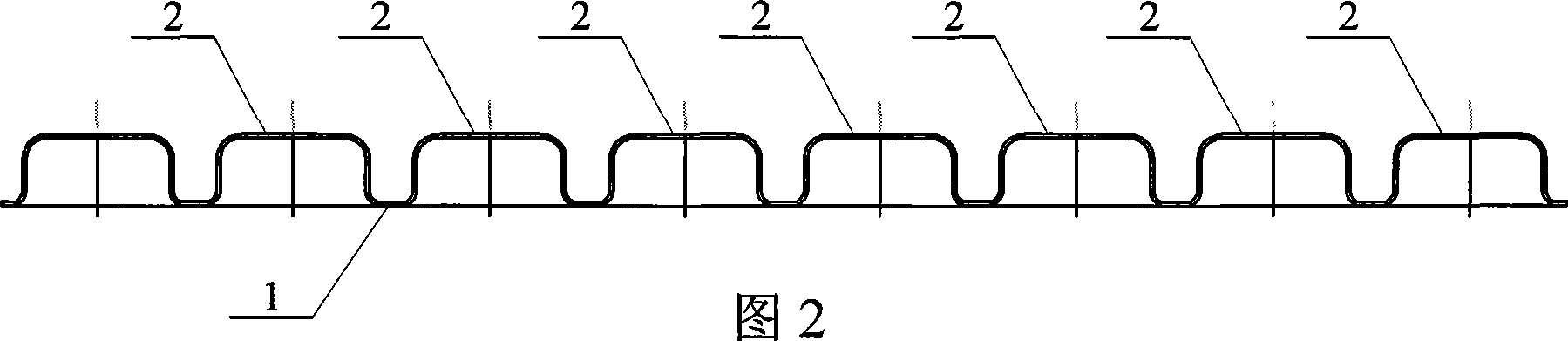

[0006] Specific implementation mode one: (referring to Fig. 1~ Figure 4 ) This embodiment includes a thin-walled metal plate 1, and a plurality of cup-shaped protrusions 2 are stamped on the same side of the thin-walled metal plate 1, and the plurality of cup-shaped protrusions 2 are distributed in an array. The cross-sectional shape of the cup-shaped protrusions 2 is circular, and each cup-shaped protrusion 2 is a sub-energy absorber.

specific Embodiment approach 2

[0007] Specific embodiment two: (see Fig. 1) a plurality of cup-shaped protrusions 2 of this embodiment are arranged evenly in the horizontal and vertical directions on the thin-walled metal plate 1, and the energy absorbed by the energy absorbers is equal to that of each sub-absorber. The sum of the energy absorbed by the energy device. Others are the same as in the first embodiment.

specific Embodiment approach 3

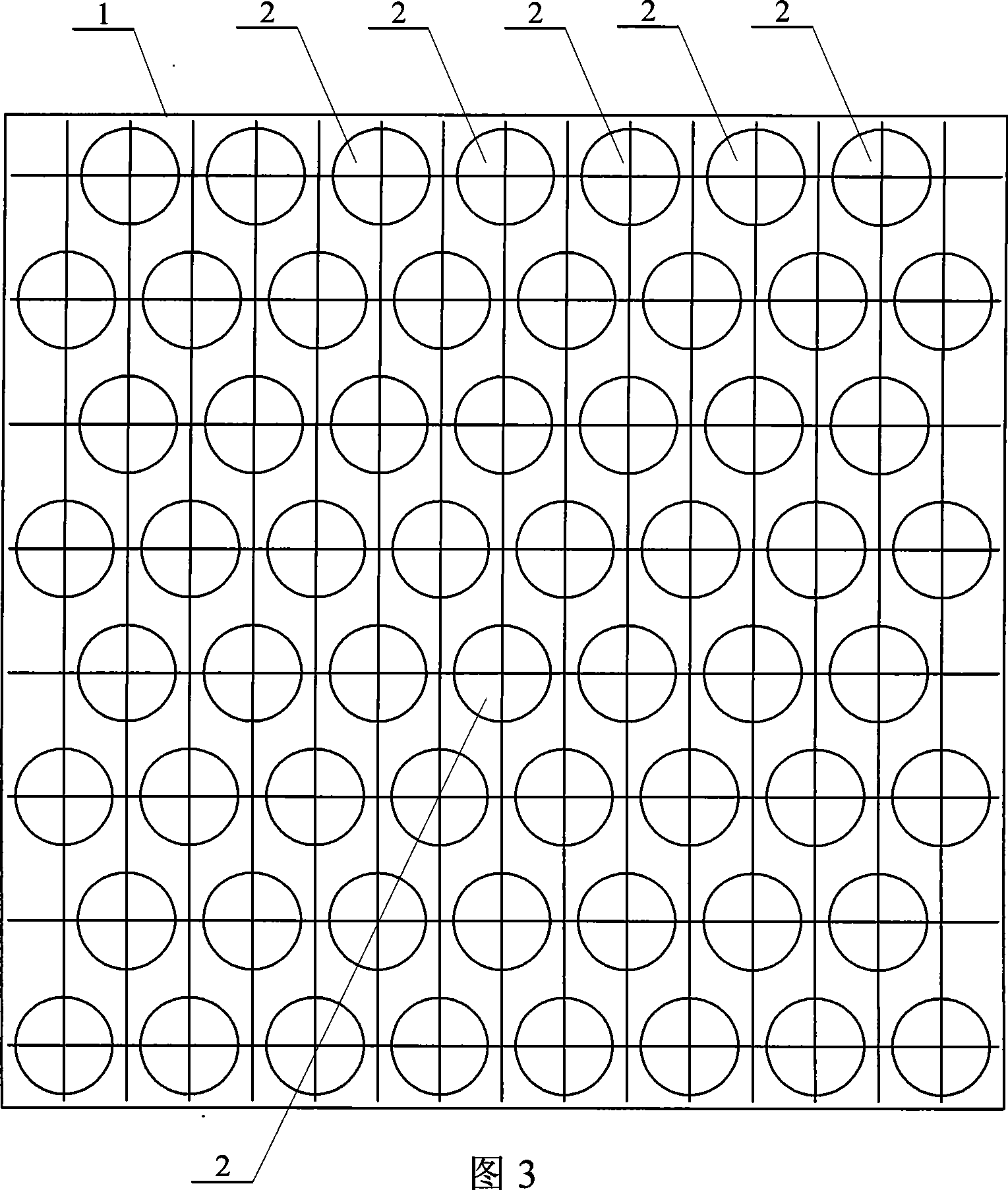

[0008] Specific embodiment three: (see Fig. 3) a plurality of cup-shaped protrusions 2 of this embodiment are dislocated and distributed on the same thin-walled metal plate 1, and the energy absorbed by the energy absorber is equal to the sum of the energy absorbed by each sub-energy absorber , due to the dislocation arrangement, compared with the specific embodiment 1, this embodiment can arrange more sub-energy absorbers, so that its energy absorption capacity is stronger. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com