Sea cucumber bait crushing mill

A pulverizer and bait technology, which is applied in the field of machinery, can solve problems such as easy damage to equipment, and achieve the effects of not being easily damaged and saving feeding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

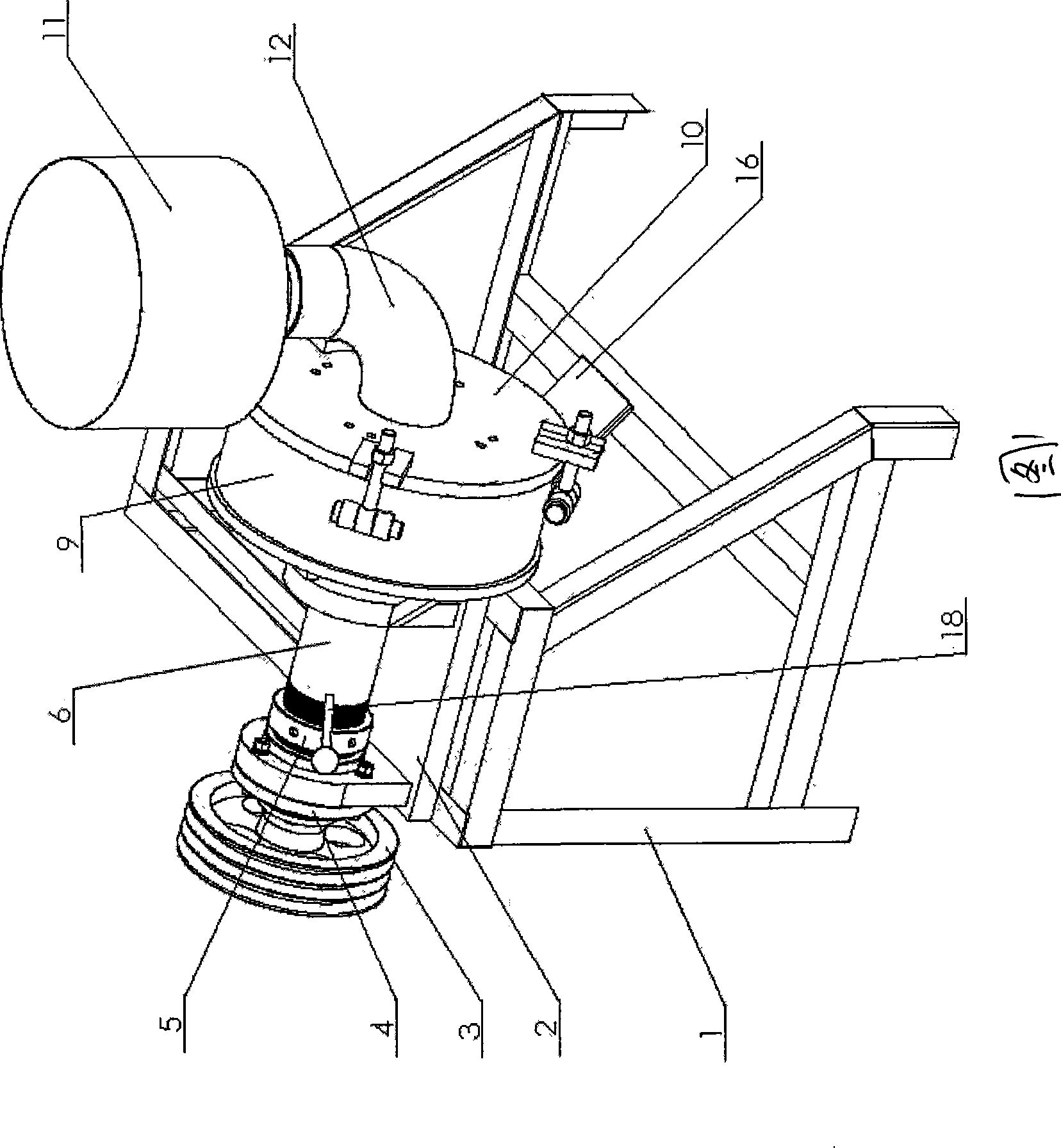

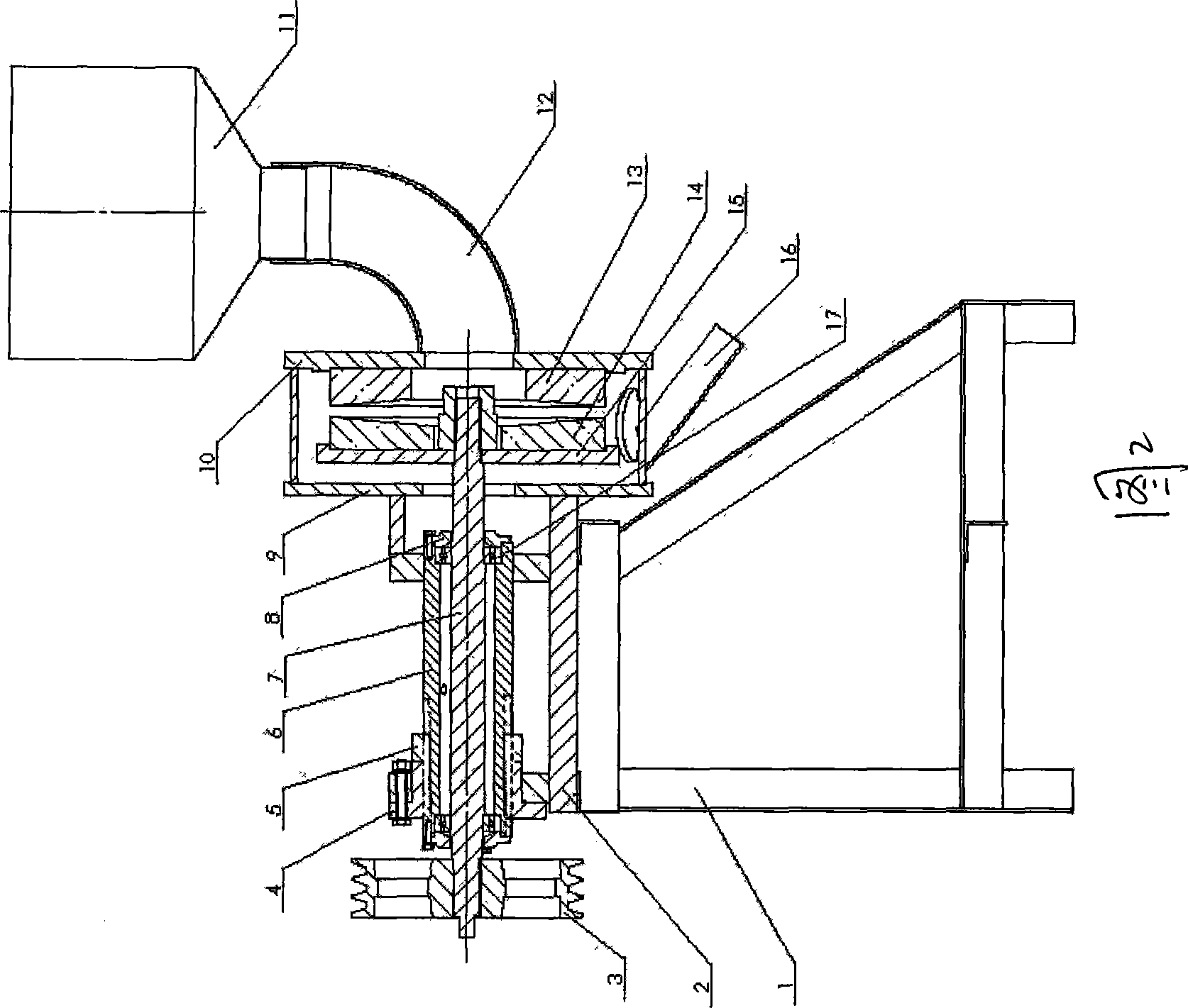

[0012] The present invention will be further described below in conjunction with accompanying drawing: A kind of sea cucumber bait pulverizer comprises support 1, and base 2, support 4 are fixedly installed on support 1, bearing sleeve 6 is set in the inner hole of support 4, and bearing sleeve 6 two ends are provided with Bearing 17, and main shaft 7 is equipped with, support 4 endoporus, bearing sleeve 6 one end outer diameters are all provided with matching screw, bearing sleeve 6 is equipped with locking ring 5, toggle lever 18, locking ring 5 The role of the fixed bearing sleeve 6, one end of the main shaft 7 is provided with a large pulley 3, and the other end passes through the rear box 9 to be provided with a rear grinding wheel seat 15 and a rear grinding wheel 14, the rear grinding wheel 14 is fixed on the rear grinding wheel seat 15, and the front grinding wheel 13 is fixed by screws Installed on the front box cover 10, the front box cover 10 links to each other with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com