Electric torsion wrench measurement structure

A torque wrench and electronic technology, applied in the field of wrenches, can solve the problems of inability to accurately measure the torque value, small strain of the measurement structure, and damage to the body structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

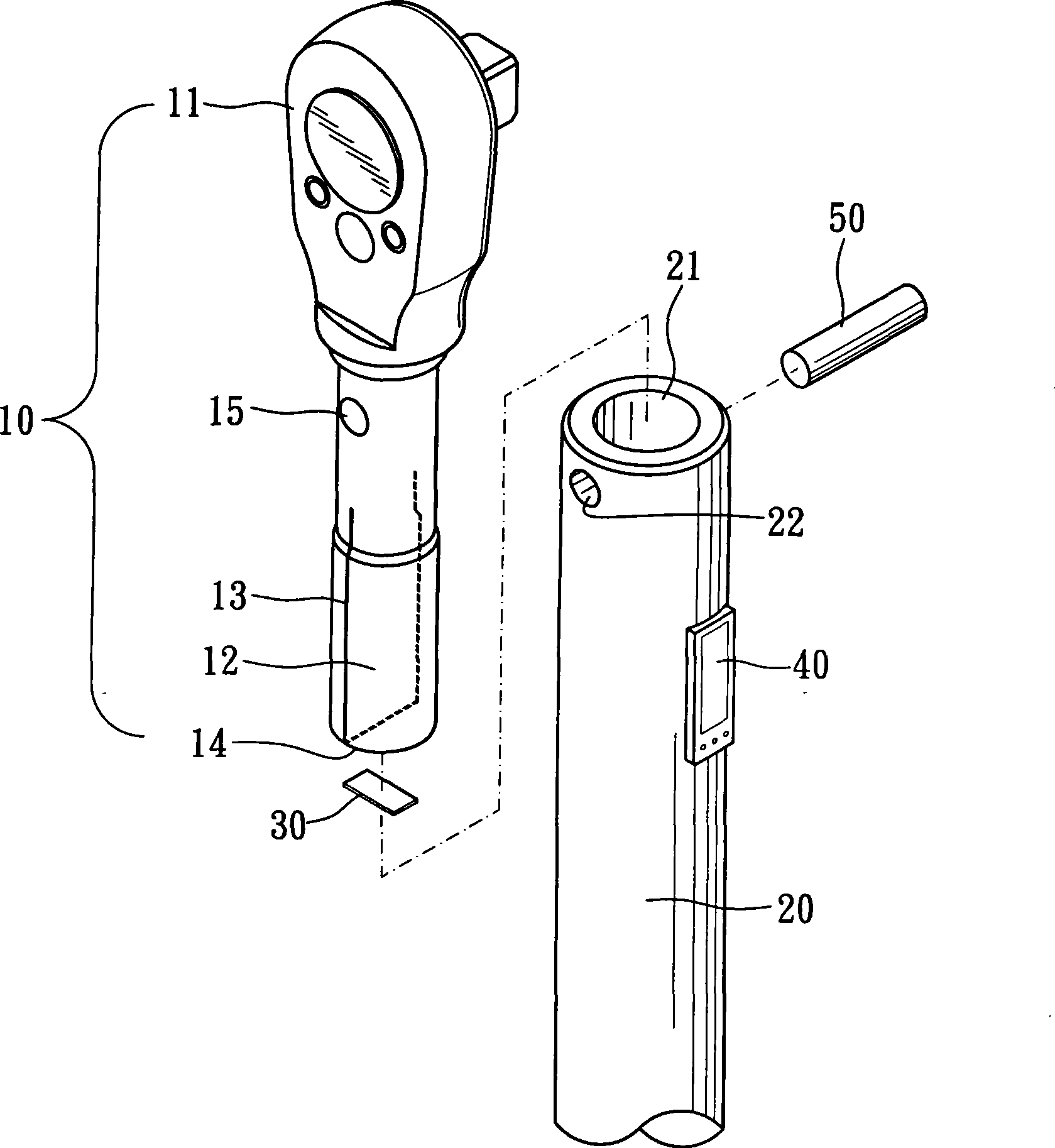

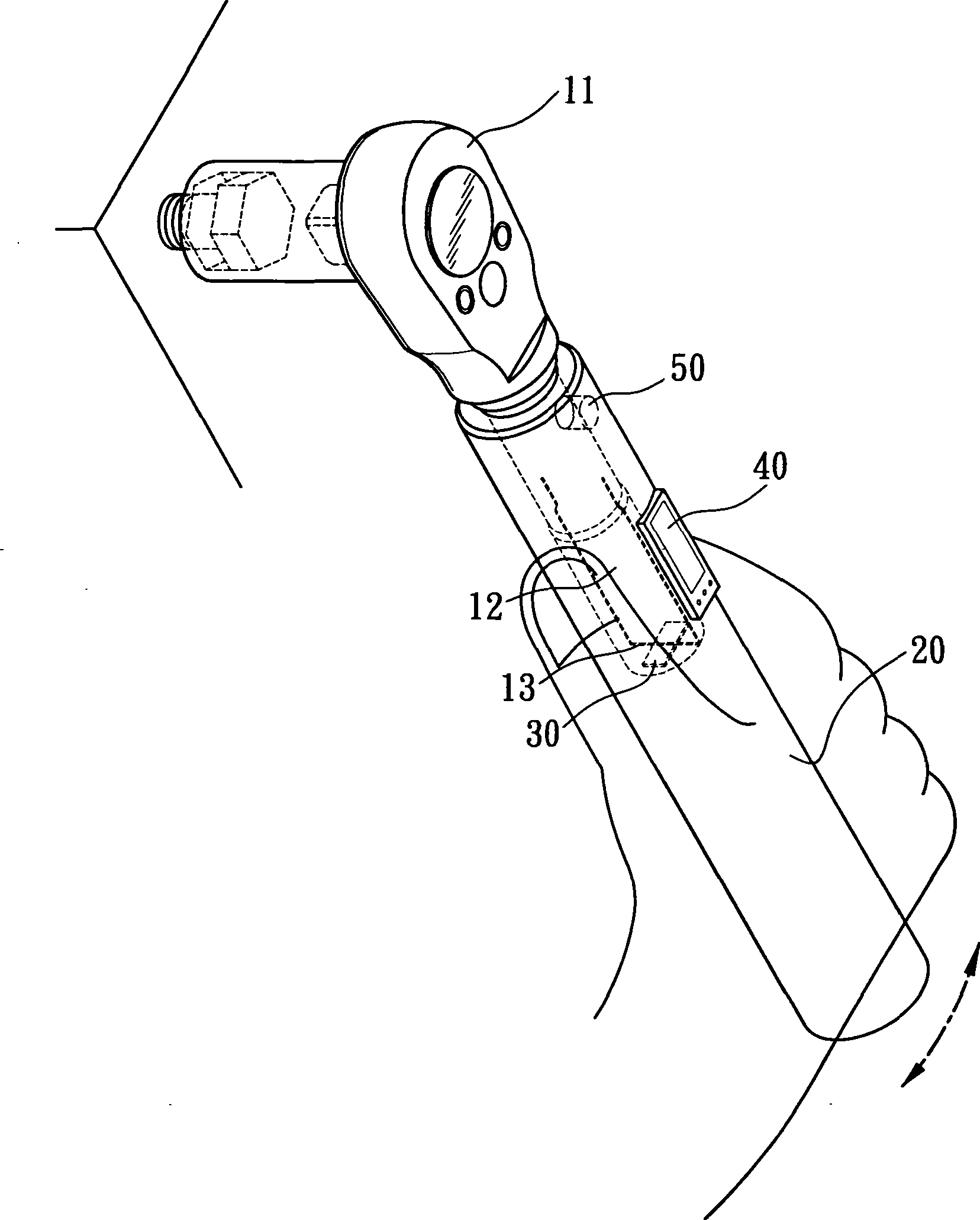

[0023] The present invention relates to a measurement structure of an electronic torque wrench, please refer to figure 1 and figure 2 As shown, it mainly includes a driving part 10, a grip part 20 and a measuring unit 30; wherein:

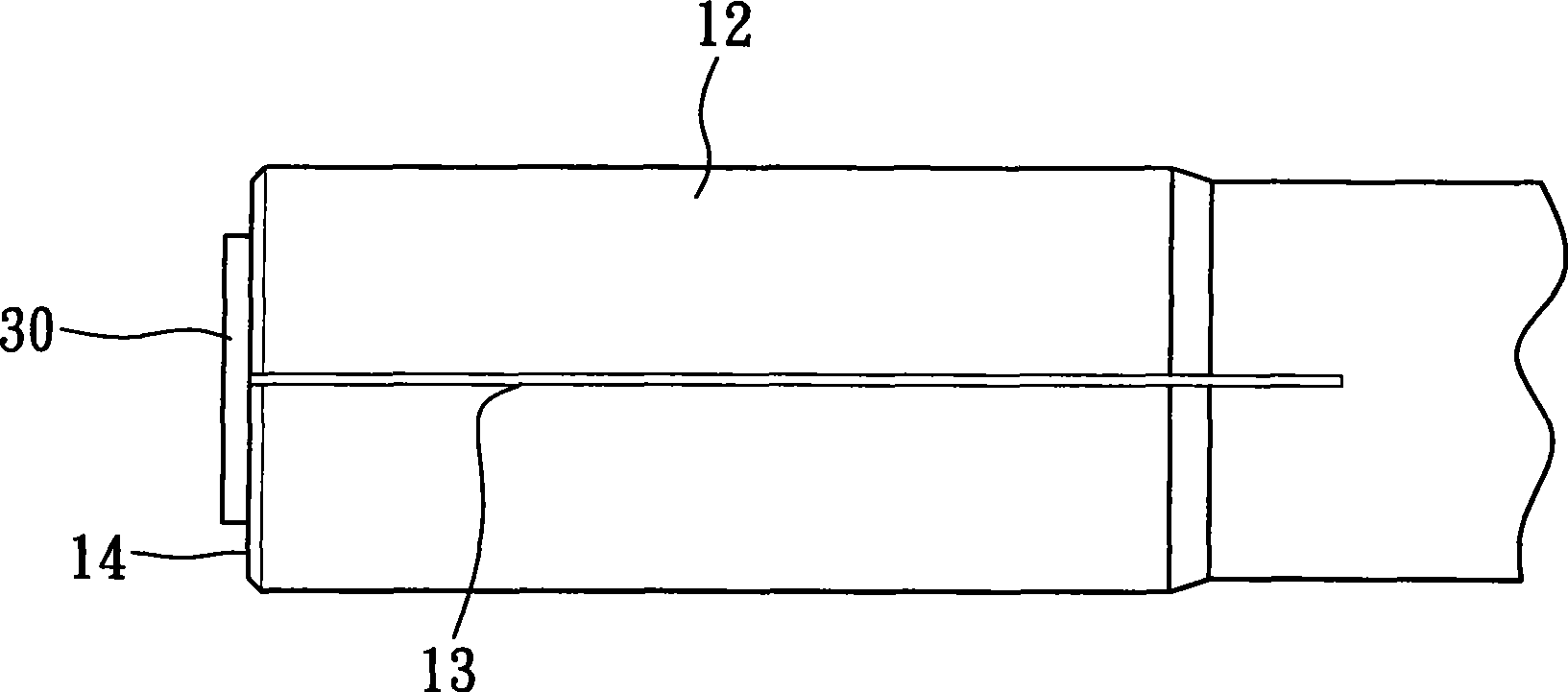

[0024] One end of the driving part 10 is provided with a driving head 11, which is sleeved with a sleeve or screwdriver bit (not shown in the figure) required for the pulling operation, and the other end is provided with a coupling section 12, which is a cylinder The joint section 12 is provided with a long and narrow slot 13. The slot 13 passes through the axis of the joint section 12 and runs through the joint section 12. The plane of the slot 13 and the plane where the screw member (not shown) pulled by the driving head 11 is located. Vertical, and one end of the coupling section 12 is the bottom surface 14, the cut groove 13 runs through the bottom surface 14 to form two semicircles, the driving part 10 is provided with a perforation 15, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com