A kind of tough paint and its coating method for steel bar anticorrosion

A coating and steel bar technology, applied in anti-corrosion coatings, coatings, devices for coating liquid on surfaces, etc. problem, to achieve the effect of strong durability, high toughness, and good densification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

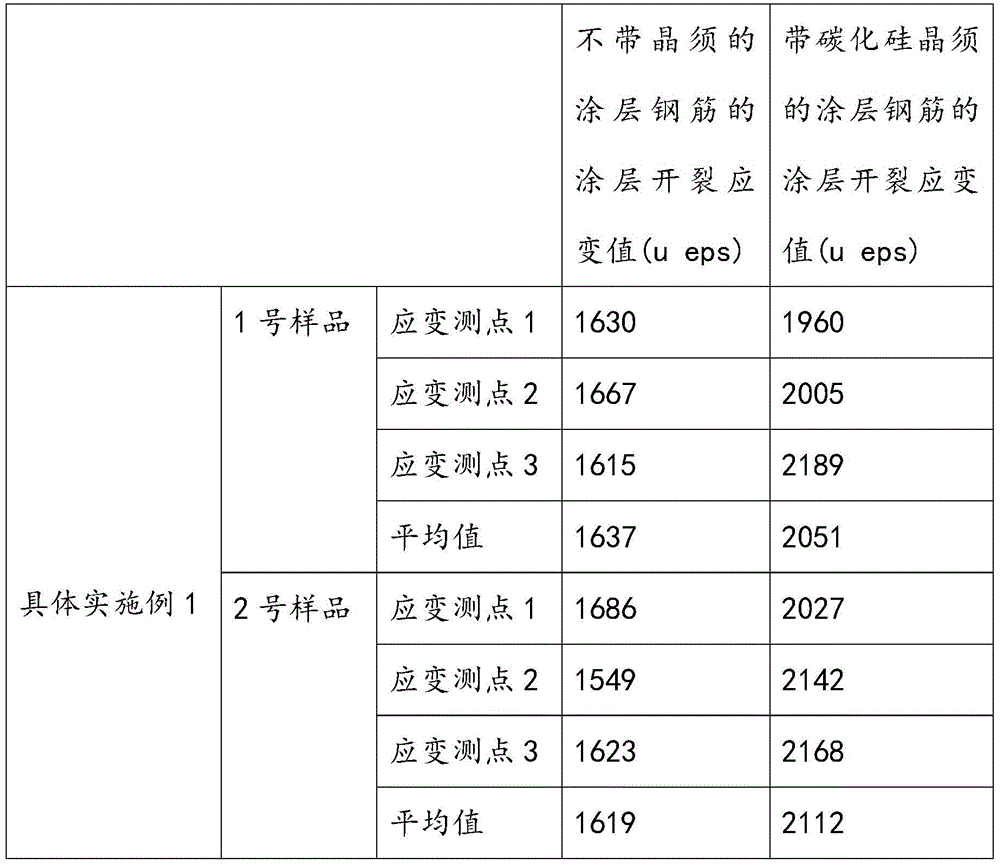

Embodiment 1

[0038] Pretreatment: Take a section of steel bar, use abrasive paper to remove rust, then rinse the surface with 5% dilute sulfuric acid to remove rust, then rinse it with clean water, and dry it for later use.

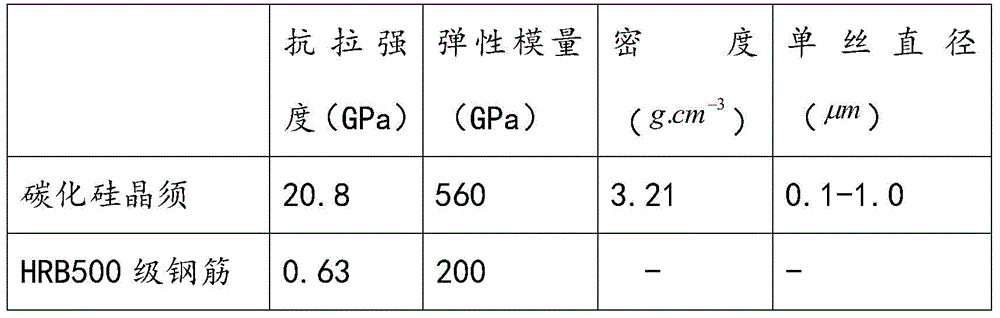

[0039] Preparation of paint: pass sericite powder through 800 mesh sieve, take 47 parts of sieved sericite powder, 40 parts of borax, 1.5 parts of silicon carbide whiskers, 5.3 parts of magnesium oxide, 5 parts of nickel trioxide, 1.2 parts of wood Element, wherein the weight ratio of sericite powder and silicon carbide whiskers is 30:1, add in the mixing tank and mix with a stirring bar for 30 seconds, then place the mixing tank in the mixer for 3-5 minutes of dry mixing , mixed well to obtain mixture A. After dry mixing, add 40 parts of water to mixture A, wherein the weight ratio of mixture A to water is 2.5:1, stir it until it becomes a slurry, put it into a mixer for wet mixing for 5-7 minutes, and mix thoroughly The paint B was obtained, and the paint B was tak...

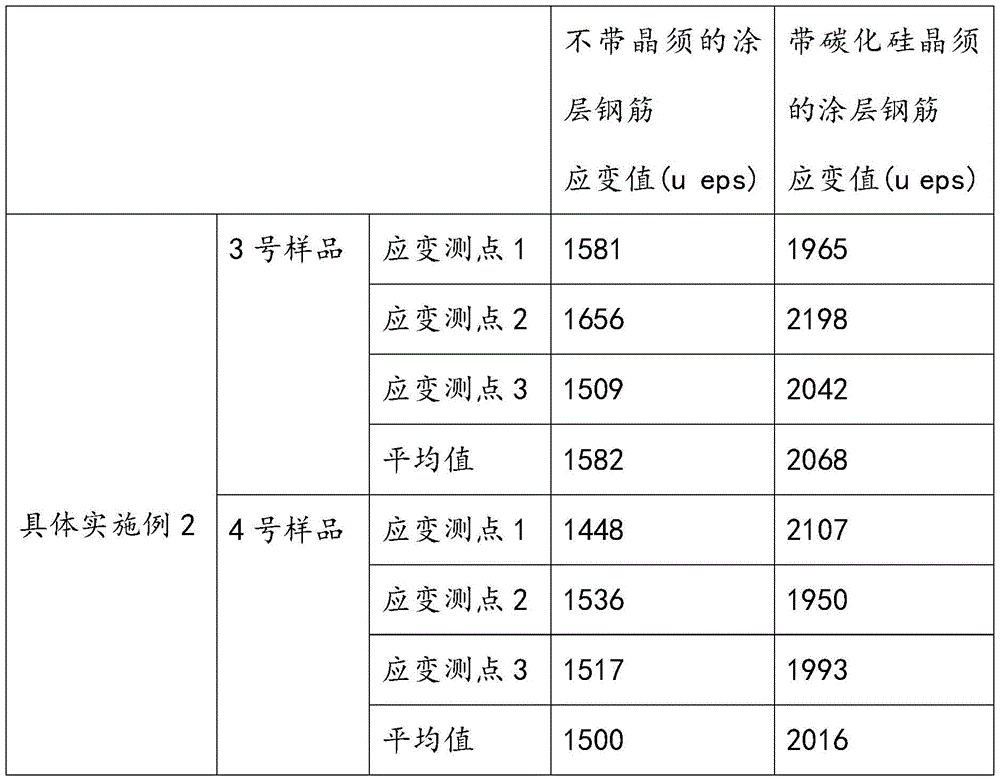

Embodiment 2

[0044] Pretreatment: with embodiment 1.

[0045] Preparation of paint: Pass the phytomica powder through a 800-mesh sieve, take 52 parts of the sieved phosphomica powder, 35 parts of borax, 2.3 parts of silicon carbide whiskers, 7.7 parts of magnesium oxide, 2.5 parts of barium molybdate, and 0.5 parts of lignin Sodium sulfonate, wherein the weight ratio of phosphomica powder and silicon carbide whiskers is 25:1, add in the mixing tank and mix with a stirring bar for 30 seconds, then place the mixing tank in a mixer for dry mixing 3- Mix well to obtain Mixture A for 5 minutes. After dry mixing, add 40 parts of water to mixture A, wherein the weight ratio of mixture A to water is 2.5:1, stir it until it becomes a slurry, put it into a mixer for wet mixing for 5-7 minutes, and mix thoroughly The paint B was obtained, and the paint B was taken out and placed in a container to stand for 10 minutes. It was observed that the paint B had no delamination and no water layer on the sur...

Embodiment 3

[0050] Pretreatment: with embodiment 1.

[0051] Preparation of paint: Pass sericite powder through a 900-mesh sieve, take 52 parts of sieved sericite powder, 35 parts of borax, 0.7 part of silicon carbide whiskers, 3.5 parts of magnesium oxide, 1.4 parts of antimony trioxide, 1.6 parts of wood element, wherein the weight ratio of sericite powder and silicon carbide whiskers is 70:1, add to the mixing tank and mix with a stirring bar for 30 seconds, then place the mixing tank in a mixer for dry mixing for 3-5 minutes , mixed well to obtain mixture A. After dry mixing, add 40 parts of water to mixture A, wherein the weight ratio of mixture A to water is 2.5:1, stir it until it becomes a slurry, put it into a mixer for wet mixing for 5-7 minutes, and mix thoroughly The paint B was obtained, and the paint B was taken out and placed in a container to stand for 10 minutes. It was observed that the paint B had no delamination and no water layer on the surface. Pour Paint B into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com