First rope synchronous continuous replacement apparatus of hoister

A hoist and first rope technology, applied in transportation and packaging, lifting equipment in mines, etc., can solve the problems of affecting coal mine production efficiency, slow rope changing speed, large space size, etc., to improve economic operation efficiency, length and size. Shorten, ensure consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

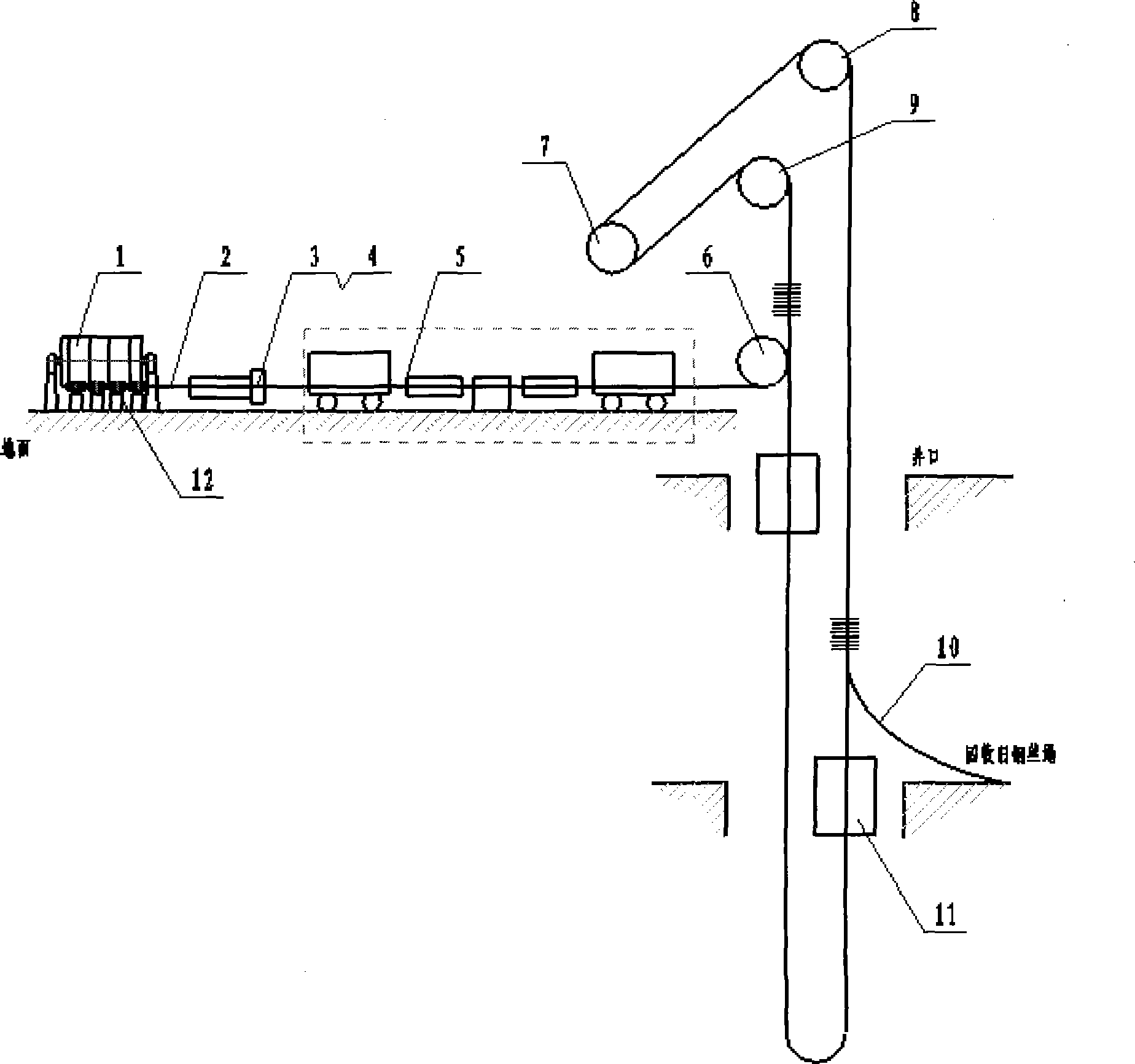

[0028] Such as Picture 1-1 As mentioned above, the device adopts the principle of "hanging the old steel wire rope 10 with the new steel wire rope 2, and recycling the old steel wire rope 10 with the new steel wire rope 2". The old wire ropes 10 go into the well at one time, fix the two cages 11 and the friction wheels 7, remove the old wire ropes 10 from the connecting device, and after making a new rope head, remove the fixing devices of the two cages 11 and the friction wheels 7, so that the cages 11 The weight of the old steel rope 10 transitions to the new steel rope 2 to bear, that is, the task of "hanging on the old steel rope 10 with the new steel rope 2" is completed.

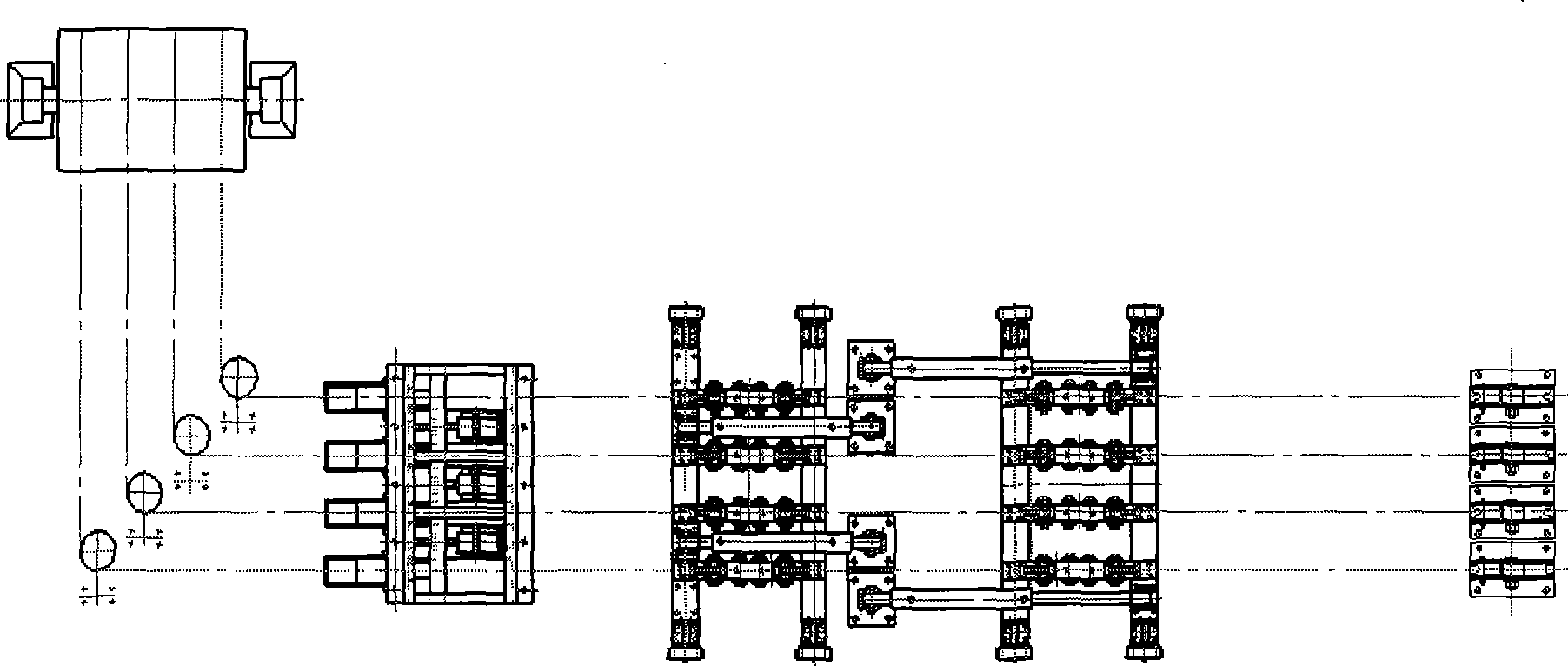

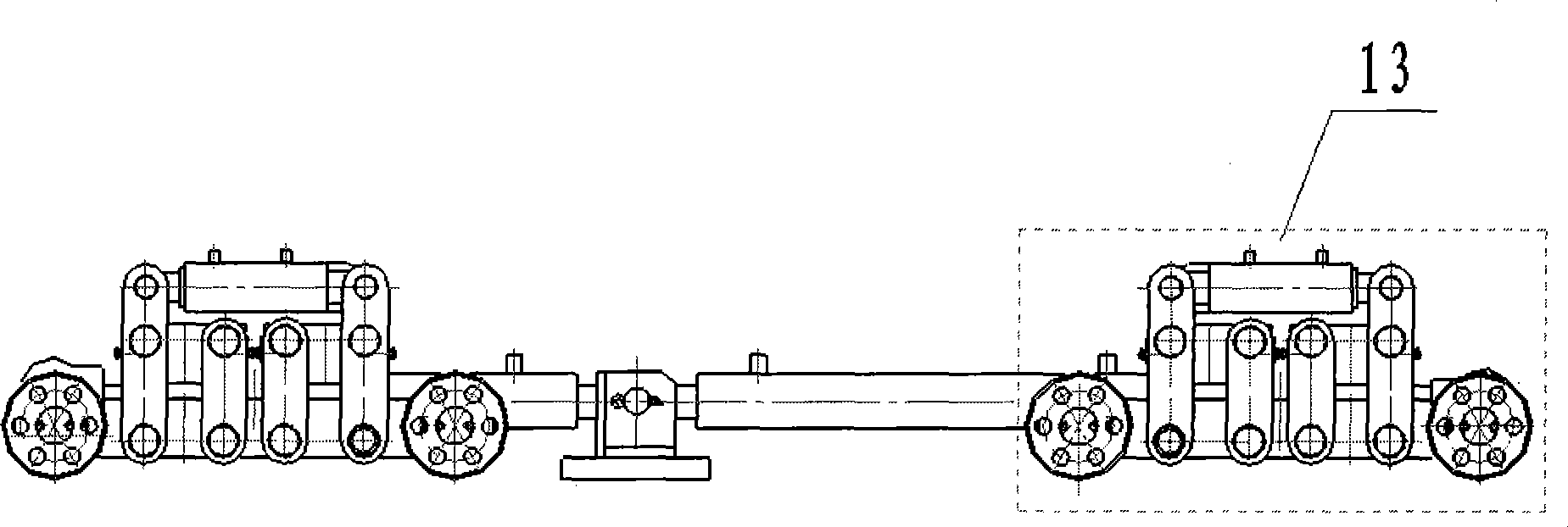

[0029] The components in the device are figure 1 The layout is fixed sequentially, and the rope is discharged from the new steel rope reel 1 that has stored a sufficient length of new steel rope 2. The new steel rope 2 first passes through the guide wheel II 12 and the anti-running rope mechanism 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com