Method for purifying non-metal inclusion in magnesium alloy by ultrasonic agglomeration

A technology of non-metallic inclusions and magnesium alloys, applied in the field of material science, can solve problems such as low production efficiency, difficulty in removing small inclusions, long operation time of flux refining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

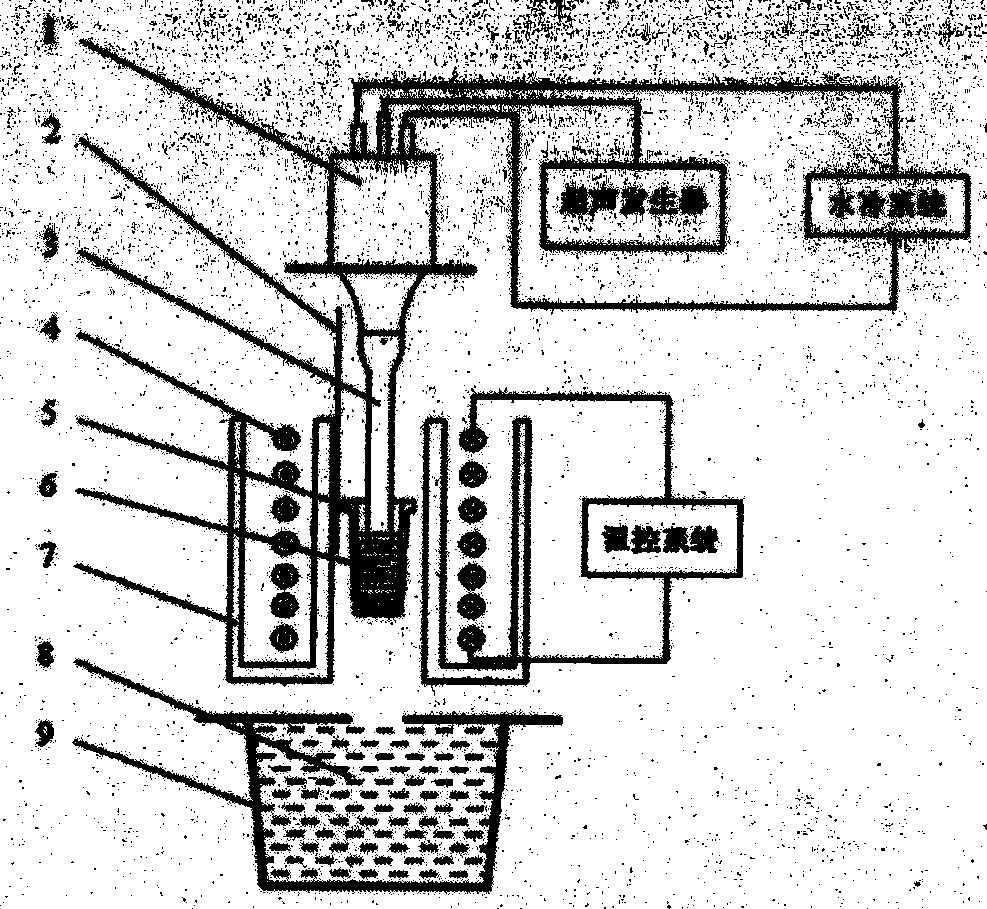

Method used

Image

Examples

Embodiment 1

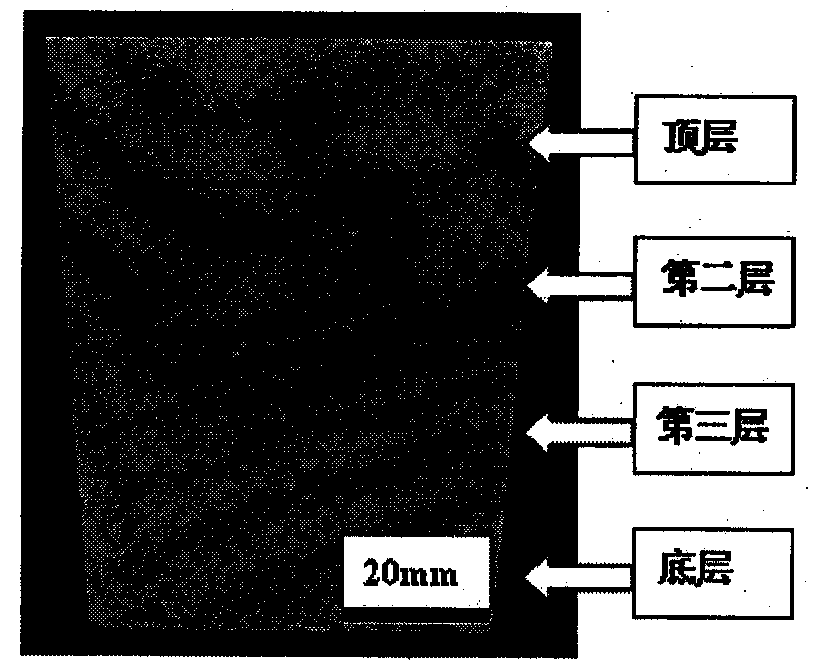

[0044] The metal magnesium and other alloying elements are melted in the iron crucible of the resistance heating furnace, and the CO 2 / SF 6 Gas, the flow rate is 5~10ml / min, and the gas composition is CO according to the volume ratio 2 : SF 6 =100:1, perform mechanical stirring, the stirring speed is 30 to 60 rpm, and the stirring time is 10 to 15 minutes. After the stirring, semi-continuous casting equipment is used for semi-continuous casting to obtain a magnesium alloy billet; A portion of 200 mm is removed from the tail end, and the remaining middle portion is used as a magnesium alloy casting billet for purification treatment, and the magnesium alloy is a GW103K (Mg-10Gd-3Y-0.6Zr) magnesium alloy.

[0045] The magnesium alloy casting billet was placed in a preheated crucible with a lid, and the preheating temperature was 200 °C; CO was introduced 2 / SF 6 gas and heating with stirring, CO 2 / SF 6 The gas flow is 5~10ml / min, CO 2 / SF 6 The gas composition is CO by ...

Embodiment 2

[0050] The preparation method of the magnesium alloy billet is the same as that in Example 1, and the magnesium alloy is GW103K magnesium alloy.

[0051] The magnesium alloy casting billet was placed in a preheated crucible with a lid, and the preheating temperature was 300 °C; CO was introduced 2 / SF 6 gas and heating with stirring, CO 2 / SF 6 The gas flow is 5~10ml / min, CO 2 / SF 6 The gas composition is CO by volume 2 : SF 6 = 100:1, the stirring speed is 30-60 rpm, and the temperature is heated to 710° C. to make the magnesium alloy casting billet into a magnesium alloy melt.

[0052] The ultrasonic rod of the ultrasonic generator is preheated to 710 ° C, inserted into the magnesium alloy melt, and then ultrasonic waves are applied to the magnesium alloy. The ultrasonic frequency is 20 kHz, and the ultrasonic sound intensity is 0.77 W / cm respectively. 2 (Total power 30W), 0.9W / cm 2 (total power 35W) and 2.7W / cm 2 (Total power 105W), the time is 50s; after the ultra...

Embodiment 3

[0055] The preparation method of the magnesium alloy billet is the same as that in Example 1, and the magnesium alloy is GW103K magnesium alloy.

[0056] The magnesium alloy casting billet was placed in a preheated crucible with a lid, and the preheating temperature was 400 °C; CO was introduced 2 / SF 6 Mix gas and heat with stirring, CO 2 / SF 6 The gas flow is 5~10ml / min, CO 2 / SF 6 The gas composition is CO by volume 2 : SF 6 =100:1, the stirring speed is 30-60 rpm, and the temperature is heated to 745° C. to make the magnesium alloy casting billet into a magnesium alloy melt.

[0057] The ultrasonic rod of the ultrasonic generator is preheated to 745 ° C, inserted into the magnesium alloy melt, and then ultrasonic waves are applied to the magnesium alloy. The ultrasonic frequency is 20 kHz, and the ultrasonic sound intensity is 0.9 W / cm. 2 (Total power 35W), 2.96W / cm 2 (Total power 115W), 7.26W / cm 2 (Total power 280W) and 20.96W / m 2 (Total power 815W), the time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com