Assembly structure between front panel and metal plate box

An assembly structure and front panel technology, which is applied in the direction of heating devices, solar thermal devices, solar thermal power generation, etc., can solve the problems of incompatibility of maintenance convenience, and achieve the effect of easy disassembly and fastening reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

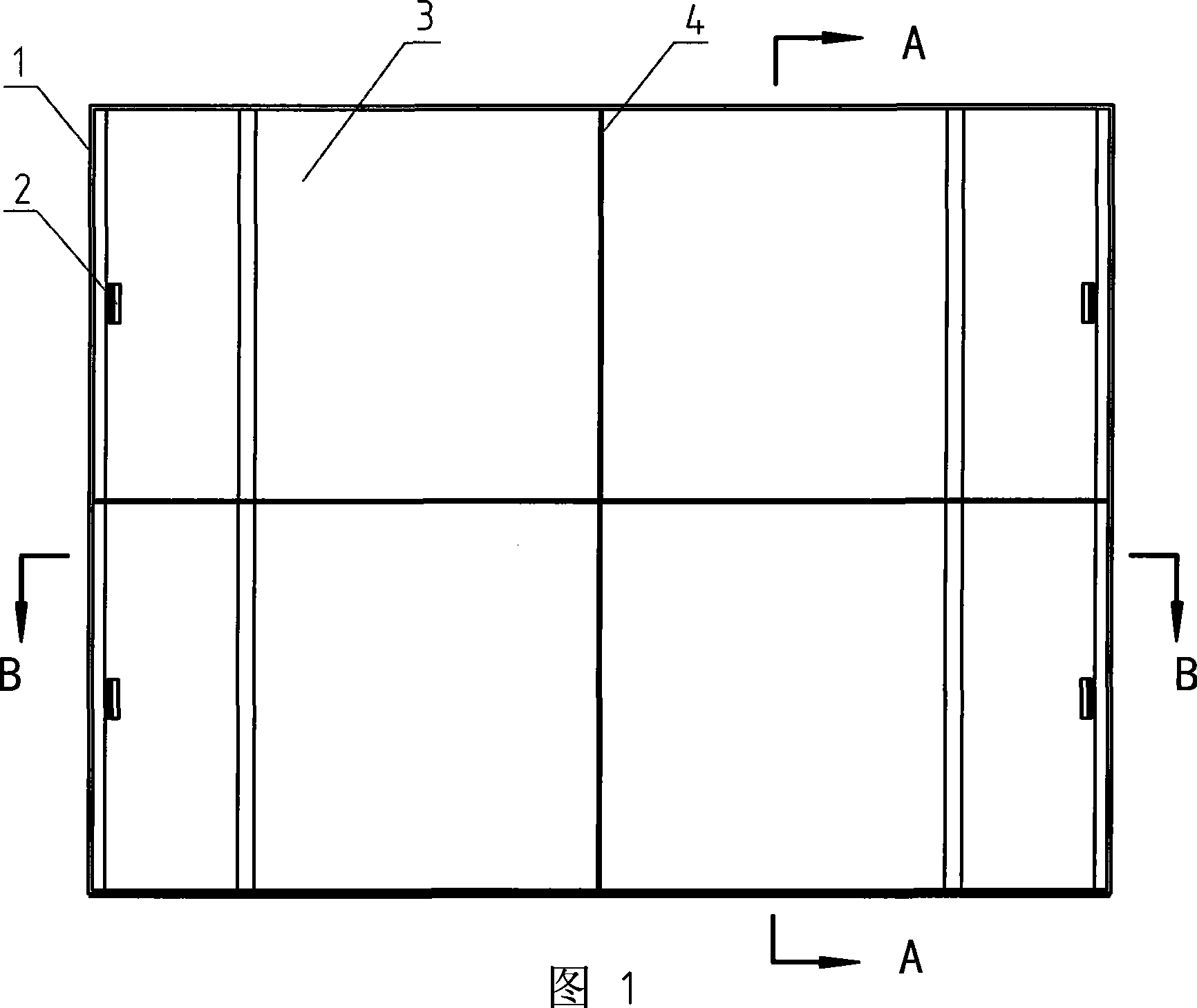

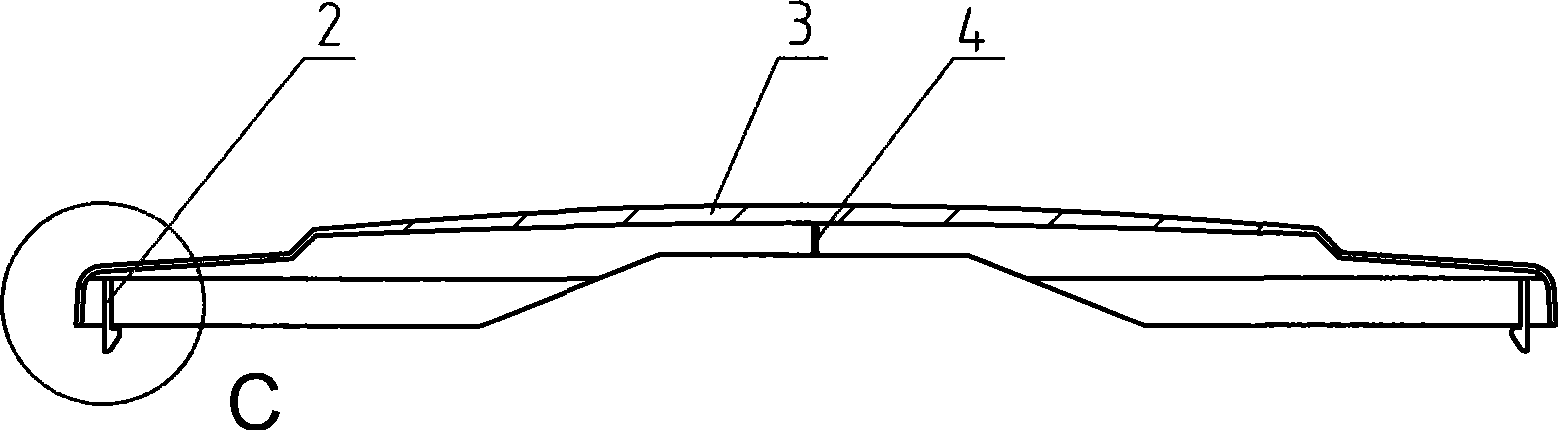

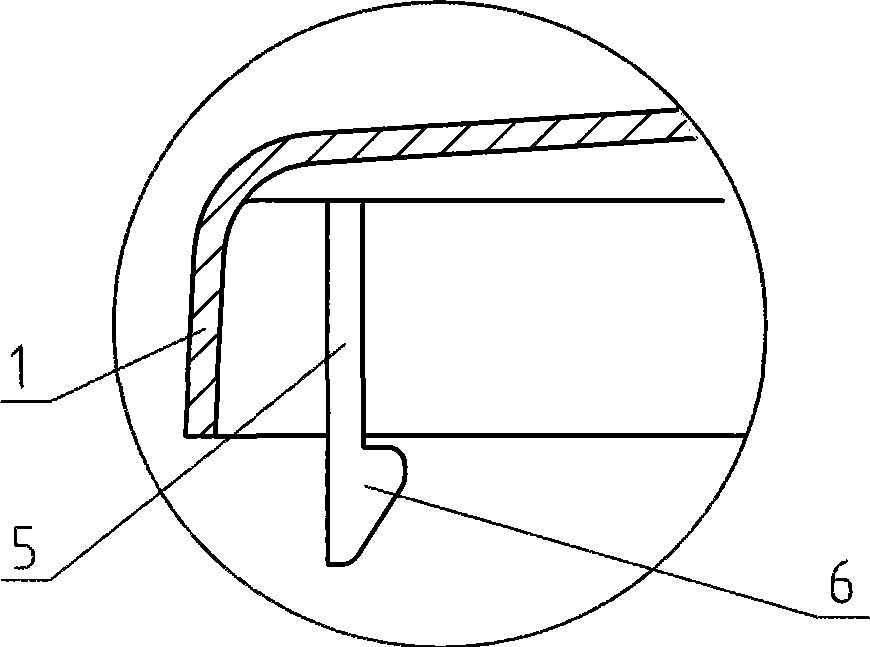

[0023] Referring to accompanying drawings 1 to 6 of the specification, aiming at the convenience of maintenance of the sheet metal box in the field of solar heat collection technology, the assembly structure of the front panel and the sheet metal box includes a sheet metal box 7 and a front panel 10 installed thereon, so The front door vertical frame 9 of the sheet metal box body is provided with a locking hole whose upper part is a wide hole 11 and the lower part is a narrow hole 12, wherein the wide hole and the narrow hole transition smoothly; the front panel is provided with a connecting locking piece corresponding to the locking hole 2. The connection lock includes a locking part 6 that is larger than the narrow hole and smaller than the wide hole and a connecting part 5 that connects the locking part and the front panel, wherein the locking part is far from the surface where the assembly joint surface 1 of the front panel is located 0.1-0.25mm longer than the thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com