Heat pipe type intercooler for vehicle

A heat pipe and cooler technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as the reduction of aluminum strength, achieve the effect of reducing intake air temperature and solving thermal fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

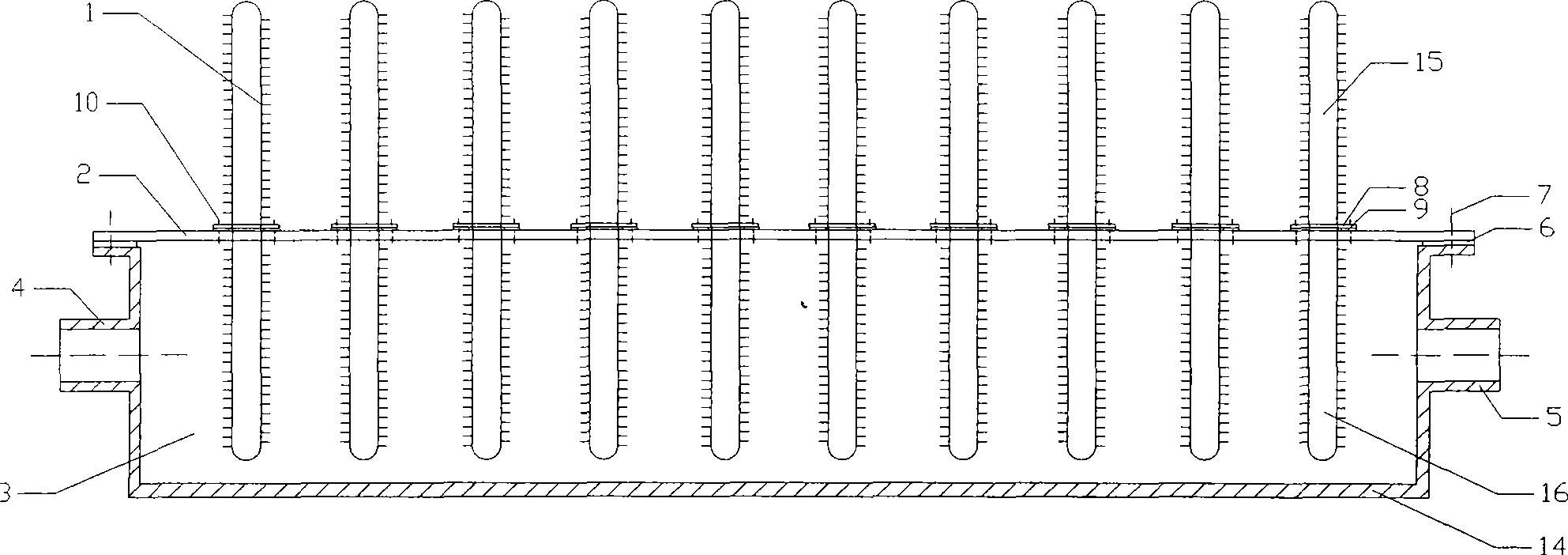

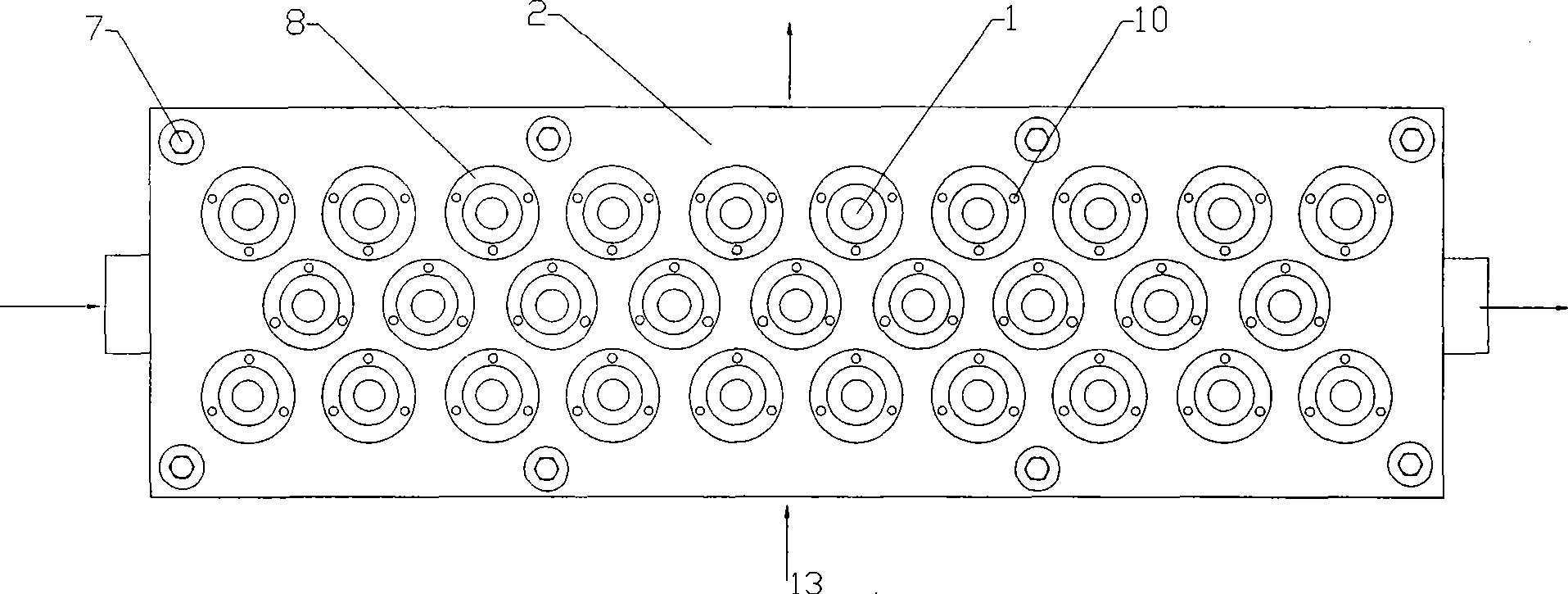

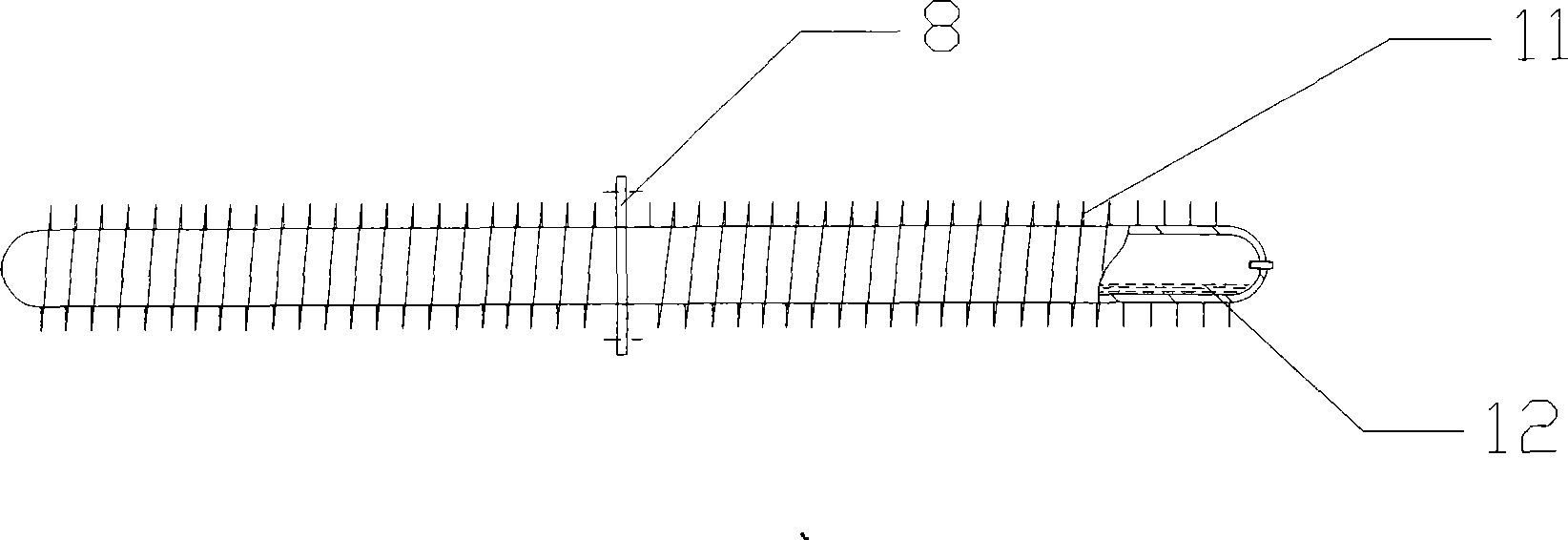

[0016] Such as figure 1 , figure 2 As shown, the heat pipe type intercooler for vehicles of the present invention includes an integral copper finned tube 1, a partition plate 2 and a concave bottom shell 14, the concave bottom shell 14 includes an air inlet 4 and an air outlet 5, and the concave bottom shell 14 includes an air inlet 4 and an air outlet 5. The shell 14 and the partition plate 2 are connected by bolts 7 to form an air intake chamber 3, and an asbestos pad 6 is installed at the joint to form a seal. Holes are staggered on the partition 2, the flange 8 is set outside the integral copper finned tube 1 and welded on the integral copper finned tube 1, the integral copper finned tube 1 passes through the holes on the partition 2, The flange 8 is connected with the partition 2 at the opening. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com