Coiled type battery pole, preparation thereof and battery comprising the pole

A battery pole, winding technology, applied in the field of winding battery pole core and its preparation, can solve problems such as battery short circuit, and achieve the effect of saving cost, avoiding direct contact, and eliminating the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

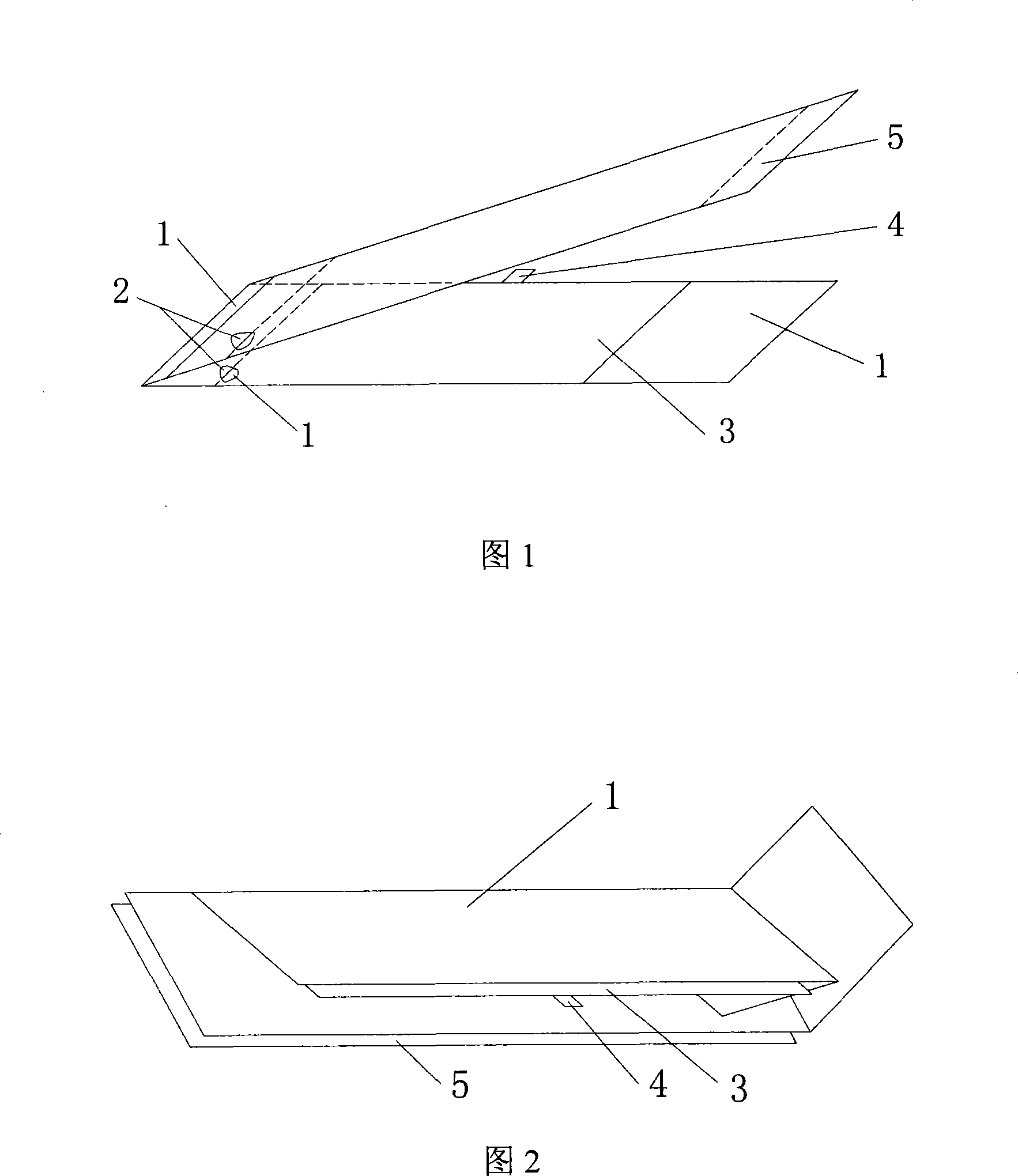

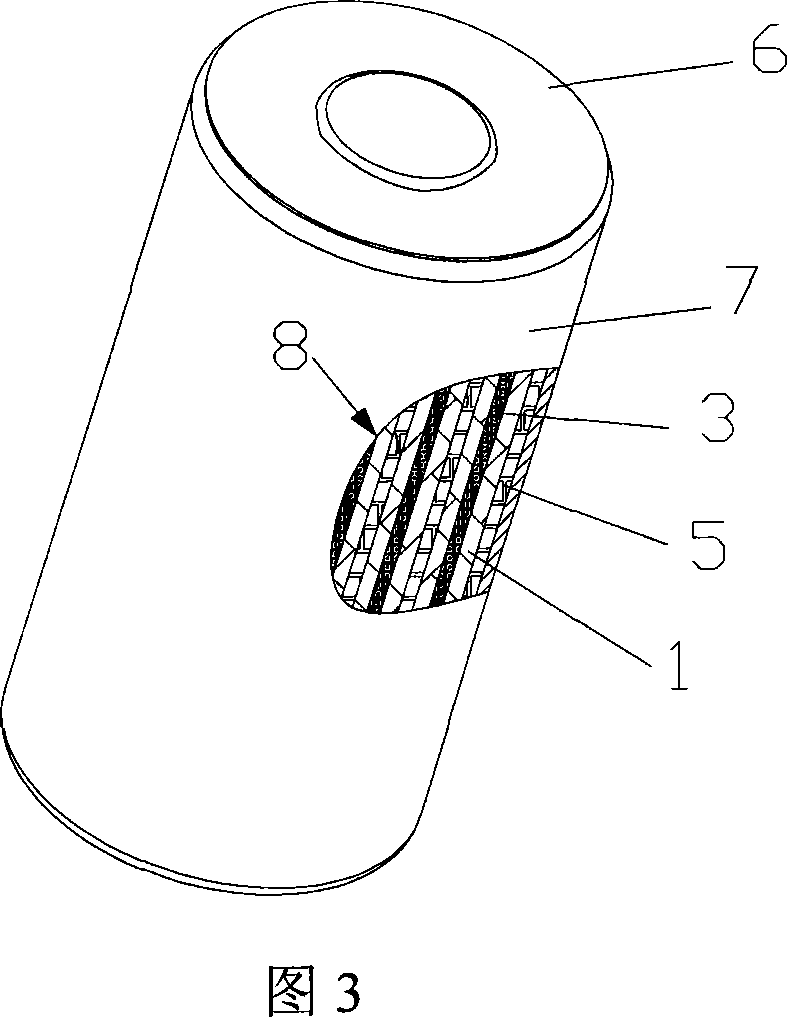

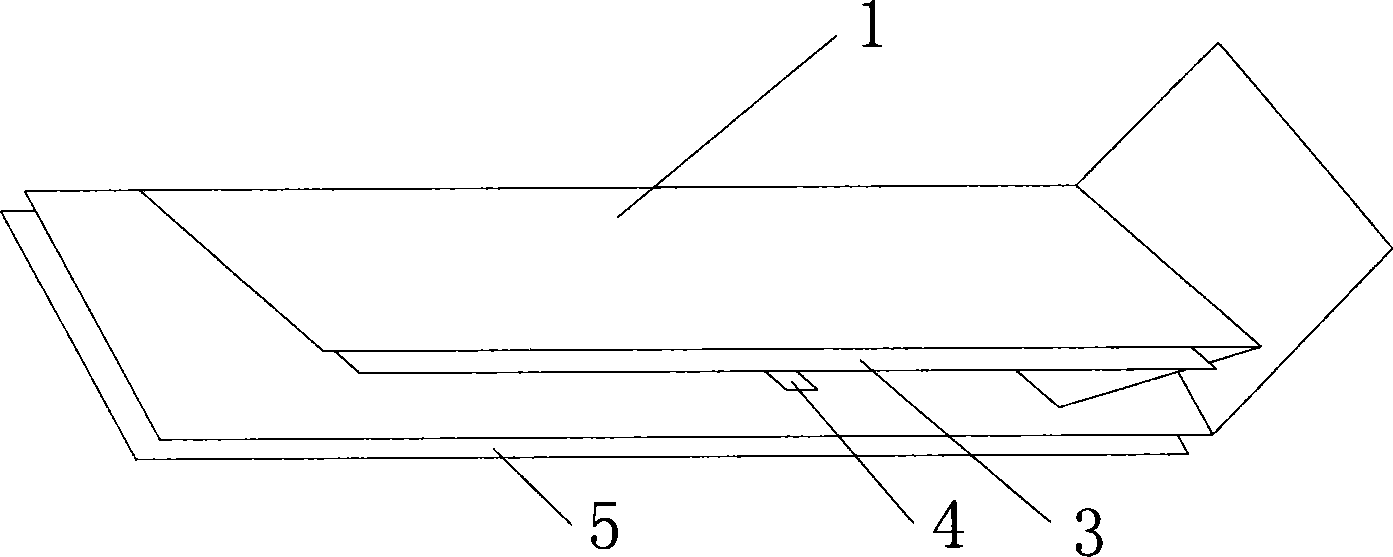

[0017] Such as figure 2 As shown, the wound battery pole core of the present invention includes a positive electrode sheet 3, a separator paper 1 and a negative electrode sheet 5 that are stacked and wound together in sequence. Before winding, the positive electrode sheet 3 is placed in a direction along the width direction Inside and completely covered by the separator paper 1 folded in half, the tab 4 of the positive electrode sheet 3 is exposed outside the separator paper 1, the negative electrode sheet 5 is located outside the double-folded separator paper 1 and the tail end of the negative electrode sheet 5 is exposed to the separator paper 1.

[0018] The winding starting end of the separator paper 1 is a double-layer semi-closed structure folded in half along the length direction, and the winding starting end of the positive electrode sheet 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com