A preparation process of a single-layer ultra-thin substrate packaging structure with a metal shielding layer and its products

A technology of metal shielding layer and preparation process, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of short circuit between product pins and metal shielding layer, time-consuming, low production efficiency, etc., to achieve Avoid the short circuit of substrate pins, avoid repeated plating, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation process of a single-layer ultra-thin substrate packaging structure with a metal shielding layer, the preparation process steps are:

[0042] 1) Perform substrate processing to obtain a single-layer substrate:

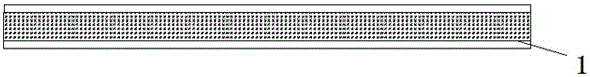

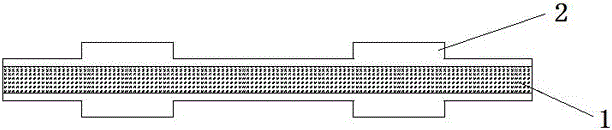

[0043] a). Take a carrier board 1, respectively press the copper layer on both sides of the carrier board 1, etch and thin the copper layer, and electroplate copper pillars 2 on the copper layer on the upper and lower surfaces of the carrier board;

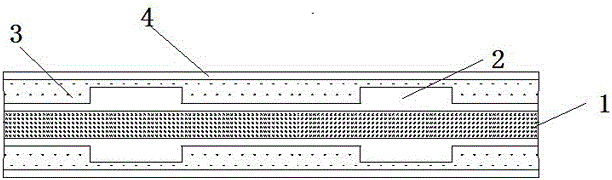

[0044] b). After the electroplating of the copper pillar 2 is completed, press the BT resin layer 3 and the metal copper layer 4 on the upper and lower surfaces of the carrier plate, so that the copper pillar 2 is encapsulated in the BT resin layer 3 to obtain a matrix;

[0045] c). Open copper windows and drill holes 5 on the substrate, electroplate the opened copper windows and drill holes 5 to form pins; carry out pattern photolithography and etching on the metal copper layer 4 on the upper part of t...

Embodiment 2

[0061] On the basis of Example 1, the substrate package was carried out, and the thickness of the single-layer substrate package A1 was obtained to be 0.3 mm. When the obtained single-layer substrate package was packaged and sealed with glue, the thickness of the glue-sealing layer A2 was 0.48 mm; When half-cutting, the thickness of the reserved back copper layer A3 is 25um, the half-cut distance B between adjacent packages is 0.8mm, and the thickness C of the metal shielding layer 13 is greater than 1um; the entire single-layer ultra-thin substrate package with the metal shielding layer 13 The thickness of the structure is 0.8 mm.

[0062] A single-layer ultra-thin substrate packaging structure with a metal shielding layer prepared according to the above method, including a metal shielding layer, a glue seal, a solder mask, a nickel or gold layer, a single-layer substrate, a BT resin layer, and a packaging component , pins; the metal shielding layer is covered on the surface ...

Embodiment 3

[0064] On the basis of Example 1, after the half cut treatment, when the pins are electroless plated in step 6), a layer of nickel is first plated on the pins, and then a layer of gold is plated, which can effectively avoid The defect of short circuit when the pin is plated.

[0065] The invention designs and develops a preparation process of a single-layer ultra-thin substrate packaging structure with a metal shielding layer and its products, and realizes effective coating of the metal shielding layer of the ultra-thin packaging structure, so that the packaging structure can achieve good electromagnetic shielding and electromagnetic shielding. Compatibility, and improve the metal shielding layer coating process for products with a single-layer ultra-thin substrate package structure, using the Half cut process to coat the entire single-layer ultra-thin substrate package product with a metal shielding layer at one time, thereby improving Production efficiency; and at the pins o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com