Electrical heating apparatus, method of manufacturing heat generator unit and pressing jig

A technology of electric heating device and heating unit, which is applied in the field of pressure fixtures, and can solve the problems of inability to complete power supply and heat generation, increase in cost and weight, and inability to obtain contact pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

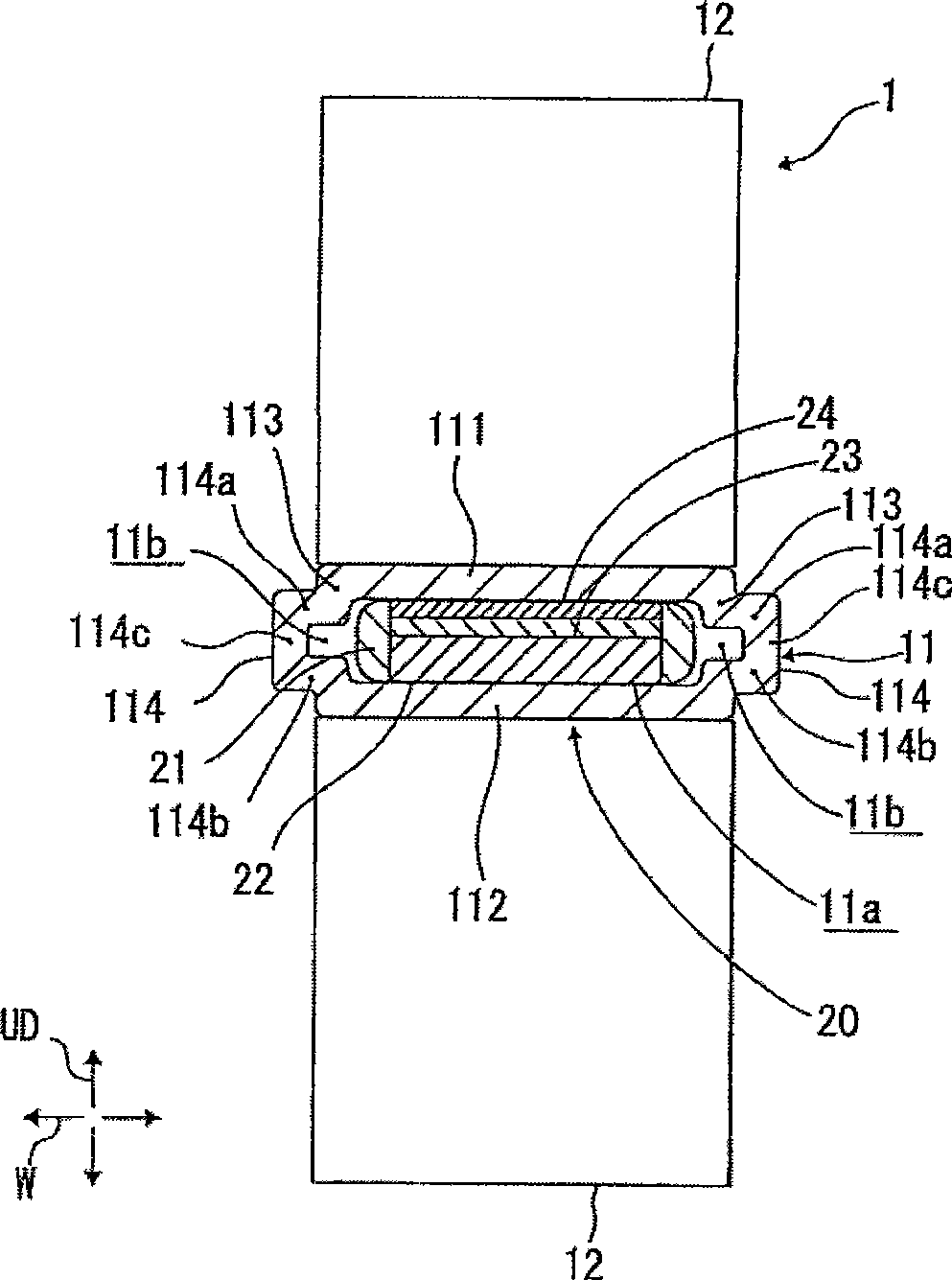

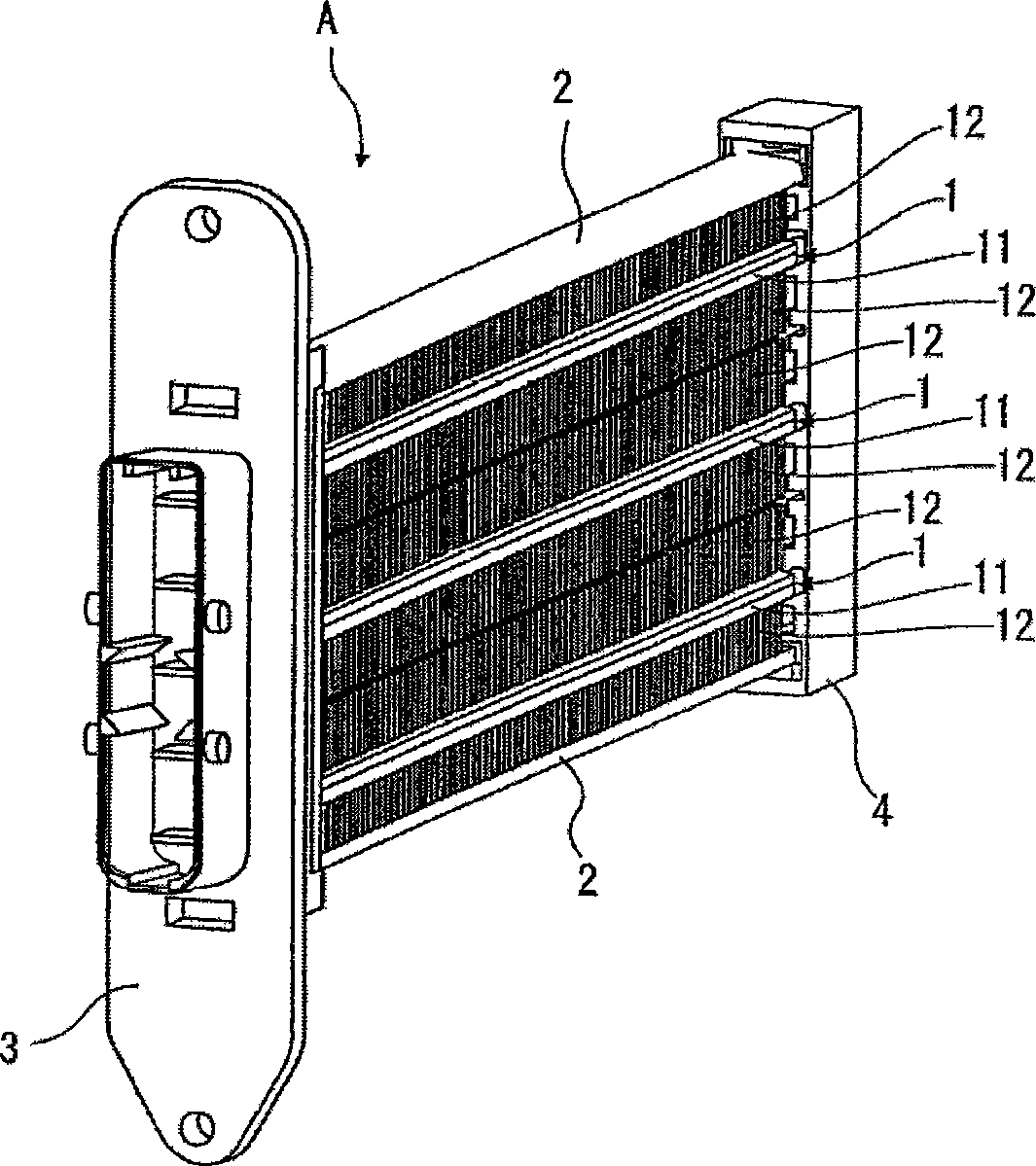

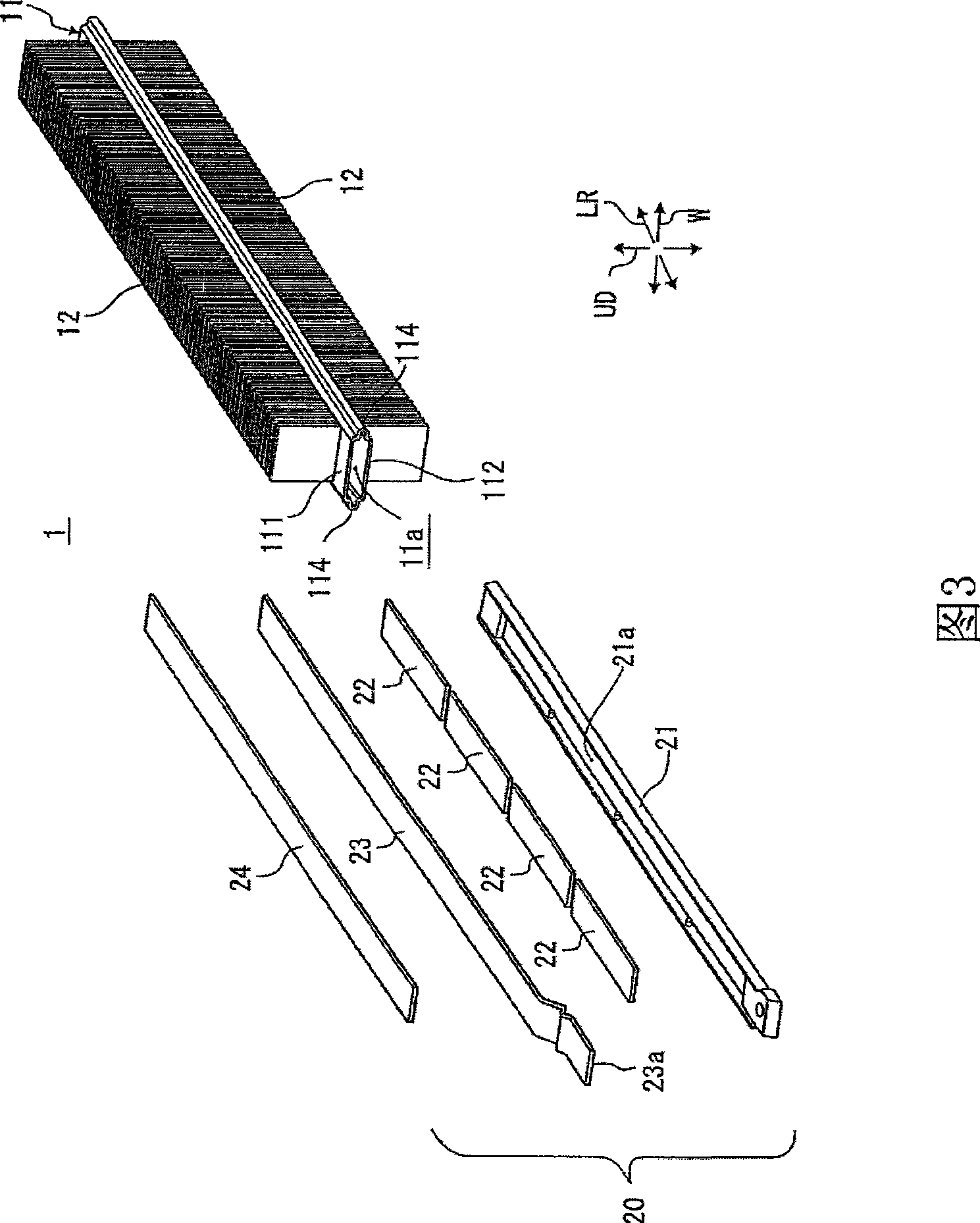

[0042] based on the following Figure 1 to Figure 7 The electrothermal device A of Example 1 which is the best mode for carrying out the present invention will be described.

[0043] The electrothermal device A of the first embodiment is used for heating and blowing air in, for example, a vehicle air-conditioning unit (not shown).

[0044] The electric heating device A is formed by stacking the heating units 1 described later in three layers along the vertical direction, then clamping them up and down with the end plates 2 and 2, and inserting the two longitudinal ends thereof into the front cover 3 and the end cover 4 to fix them.

[0045] The front cover 3 and the end cover 4 are formed of a material having excellent electrical insulation and heat resistance, such as fiber-reinforced PBT (polybutylene terephthalate: polybutylene terephthalate) or the like. The fiber-reinforced PBT exhibits excellent dimensional stability due to low water absorption and thermal expansion coe...

Embodiment 2

[0105] A method of manufacturing the heat generating unit according to Example 2 of the embodiment of the present invention will be described with reference to FIG. 8 .

[0106] This second embodiment is an example in which a substantially rectangular cylindrical pipe member without an end portion 114 is used as the pipe body 201 of the heating unit 200 .

[0107] That is, the main body upper wall 202, the main body lower wall 203, and the main body vertical walls 204 and 205 of the pipe body 201 surround the insertion space 201a having a substantially rectangular cross-sectional shape and form a substantially rectangular cylindrical cross-sectional shape.

[0108] On the outer surface of the main body upper wall 202 and the main body lower wall 203, positioning grooves 206, 206, 206, 206 for positioning the heat sink 12 in the width direction are formed on the edge portions on both sides in the width direction. Raised ribs 207, 207, 207, 207.

[0109] On both sides in the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com