Coffee making machine capable of providing steam

A coffee machine and steam technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of large steam generator, unreasonable energy utilization, and potential safety hazards, and achieve reasonable energy utilization and convenient control And humanization, the effect of improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

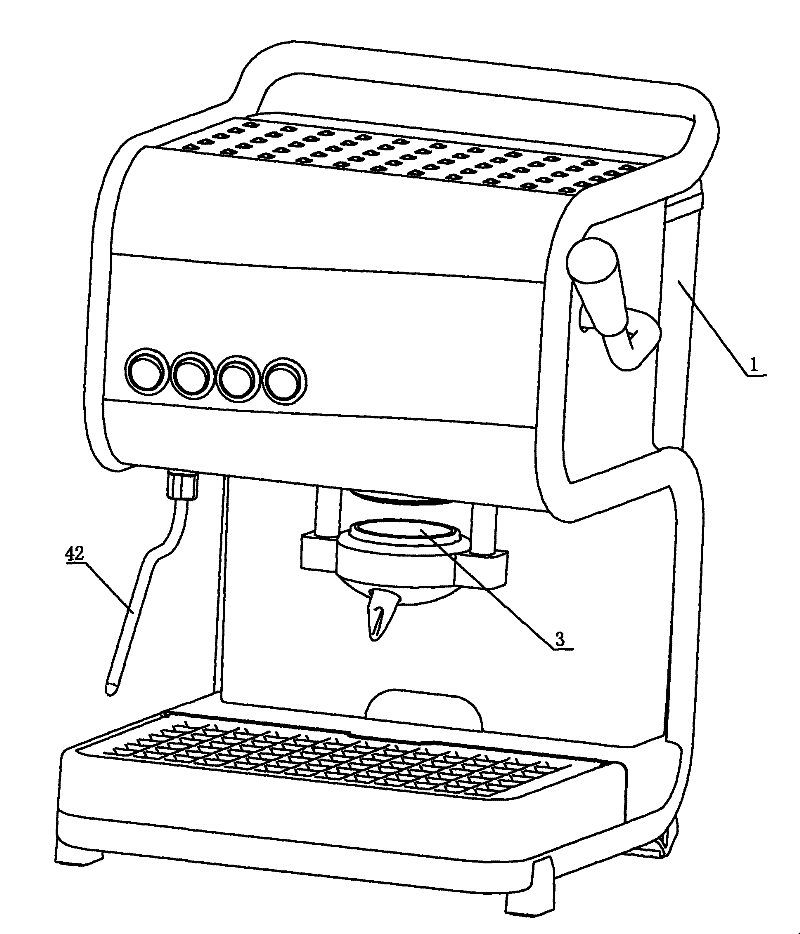

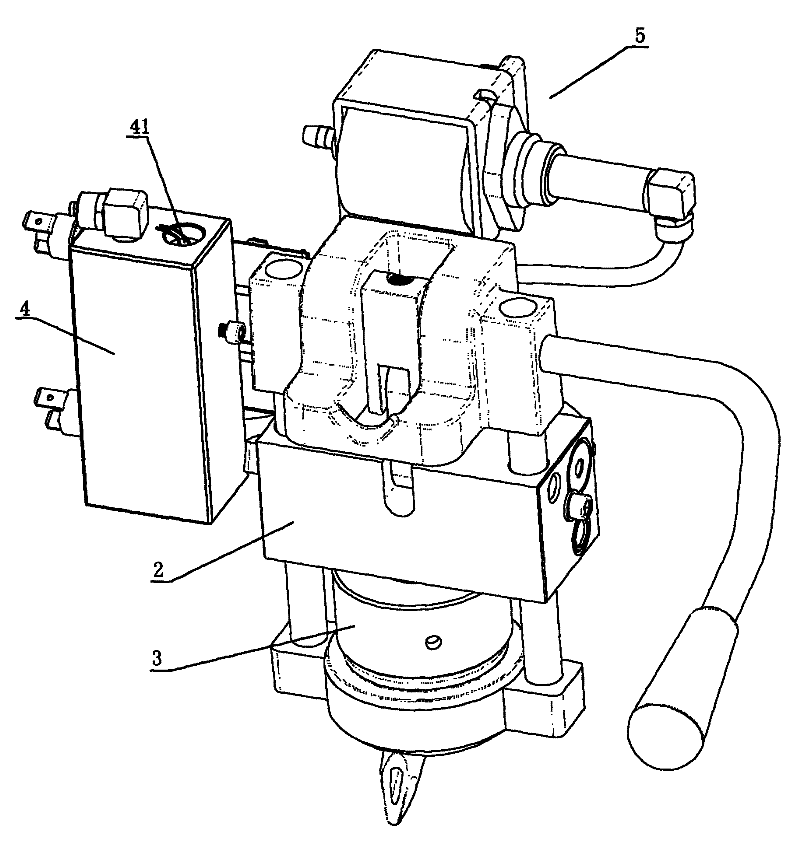

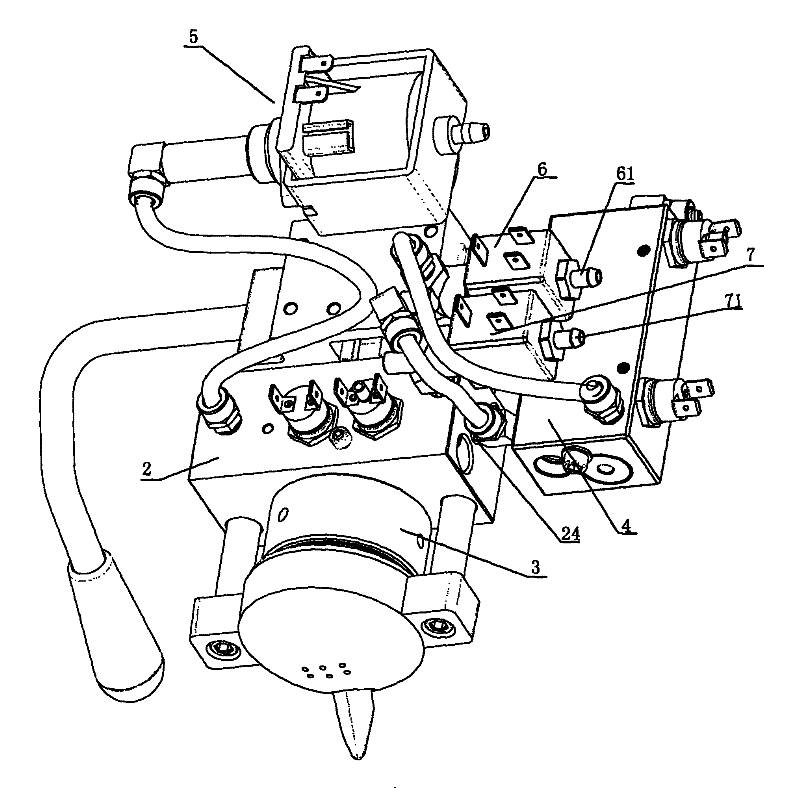

[0014] refer to Figure 1 to Figure 5 As shown, a coffee machine that can provide steam includes a water tank 1, a water heater 2, a coffee pressing device 3 and a steam generator 4. The water heater 2 and the steam generator 4 are respectively provided with electric heating pipes 21, 41. The water tank 1 A water pump 5 that can adjust the water supply pressure is provided on the pipeline between the water outlet and the water inlet of the water heater 2. The water heater 2 is provided with a first water outlet 22 and a second water outlet 23. The hot water in the water heater 2 passes through the first water outlet respectively. The water outlet 22 and the second water outlet 23 are delivered to the coffee pressing device 3 and the steam generator 4. The first water outlet 22 is provided with a first electromagnetic valve 6 on the external pipeline, and the second water outlet 23 is provided with a second electromagnetic valve on the external pipeline. valve 7.

[0015] When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com