Flat oversize blast furnace

A super-large, flat technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of coke strength and blast kinetic energy hindering the further improvement of blast furnace capacity, and reduce blast furnace height, save costs, and extend the use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

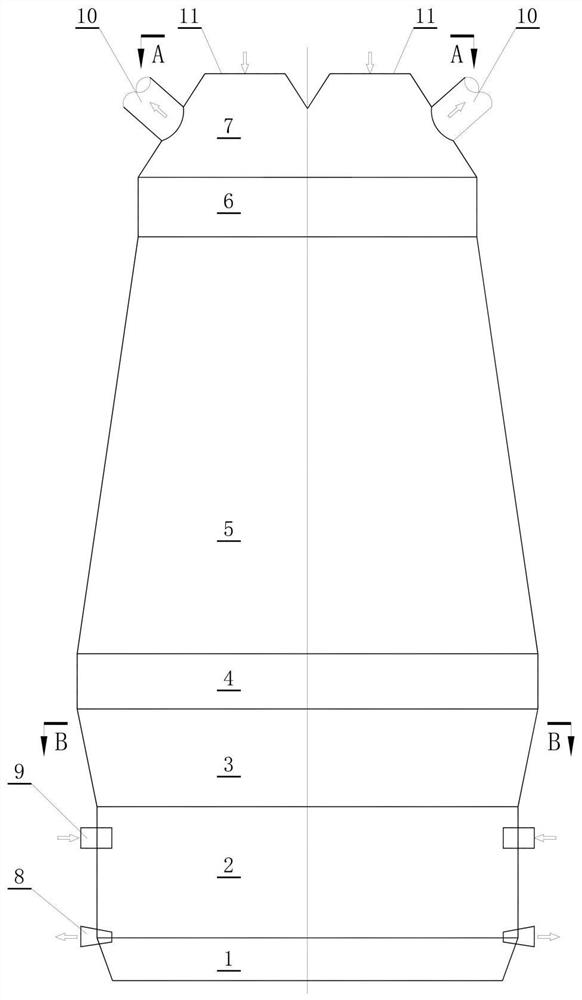

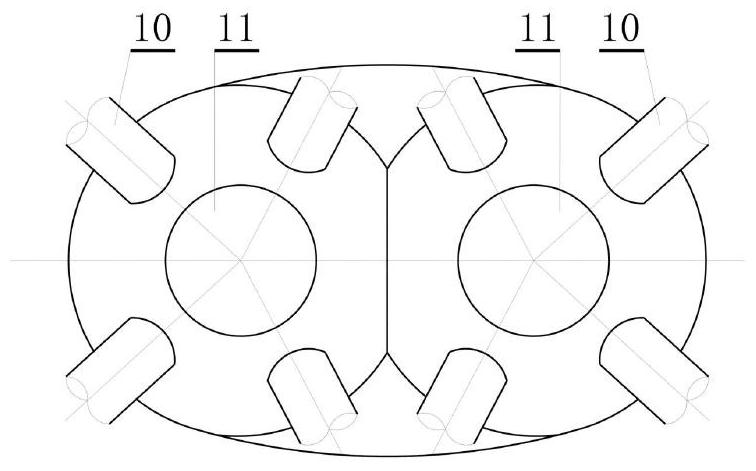

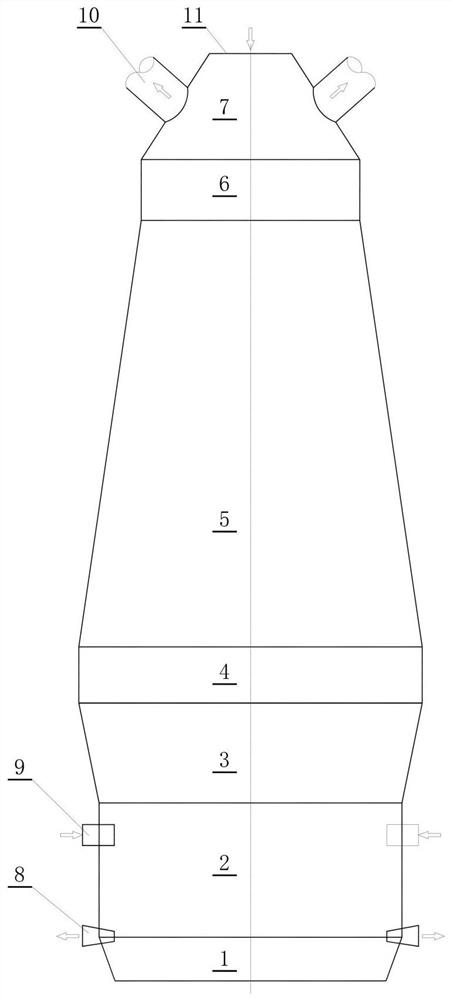

[0026] The internal shape structure of the existing blast furnace, whether it is small, large or super large, generally adopts a 7-stage design, that is, from bottom to top, it includes dead iron layer 1, hearth 2, bosh 3, furnace waist 4, and furnace body 5. Furnace throat 6 and gas enclosure 7, wherein a molten iron outlet 8 is provided between the dead iron layer 1 and the hearth 2, an air supply inlet 9 is provided on the upper part of the hearth 2, and a gas outlet 10 is provided on the side of the gas enclosure 7, The upper end of the gas enclosure 7 is provided with a raw material inlet 11, and various facilities such as the furnace shell, stave and refractory materials are provided on the blast furnace body, and the belly angle, furnace body angle, and the proportions of each section are determined according to the process requirements; Coke strength, blast kinetic energy, and the volume of the blast furnace have been greatly hindered on the road to further increase, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com