Method for pretightening and installing microseismic sensor of underground coal mine anchor rod

A microseismic sensor and sensor technology, applied in seismic signal receivers, seismology for logging records, seismology, etc., can solve the problems of lack of installation methods, large labor, waste of materials, etc. The effect of reducing labor intensity and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

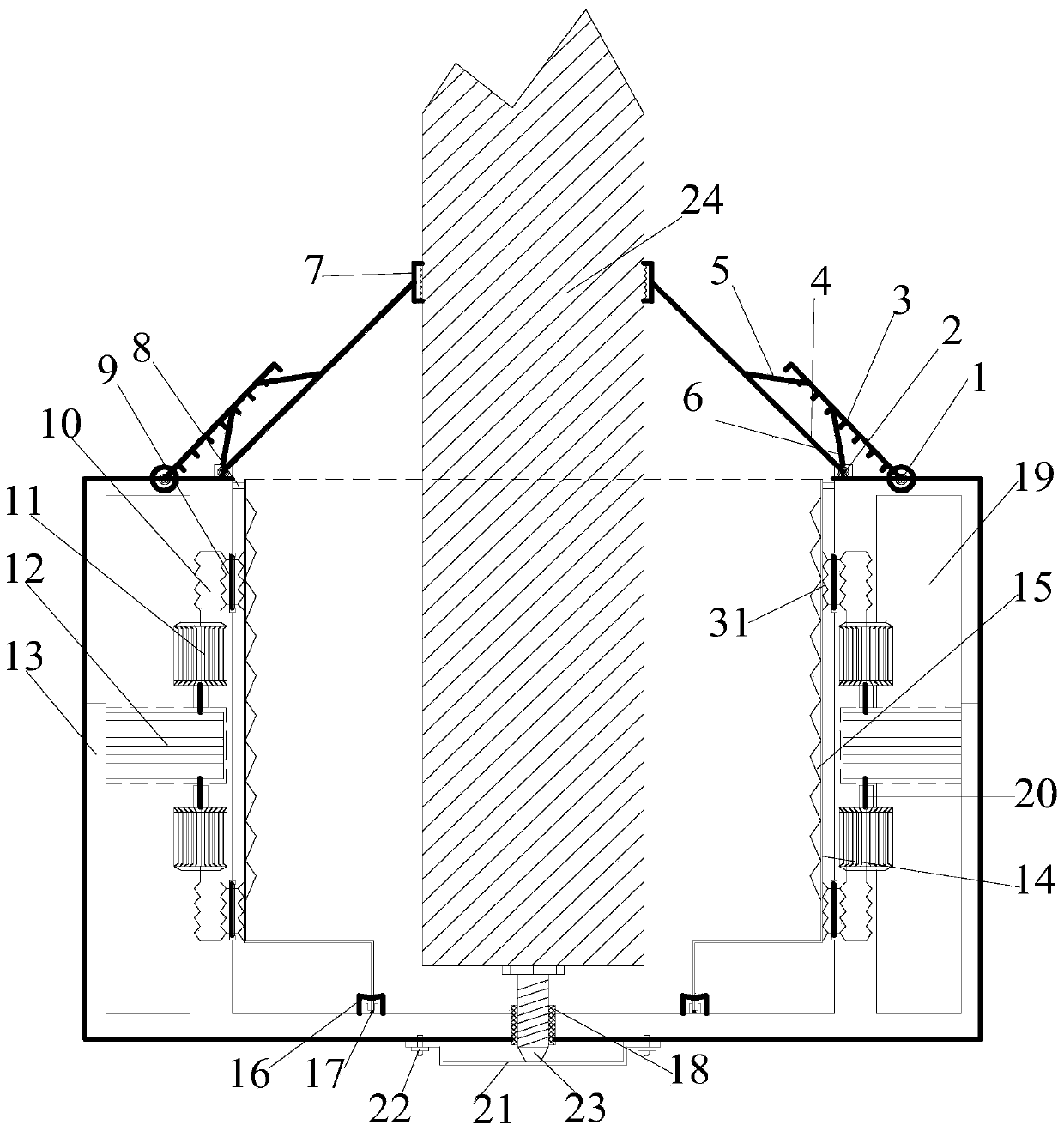

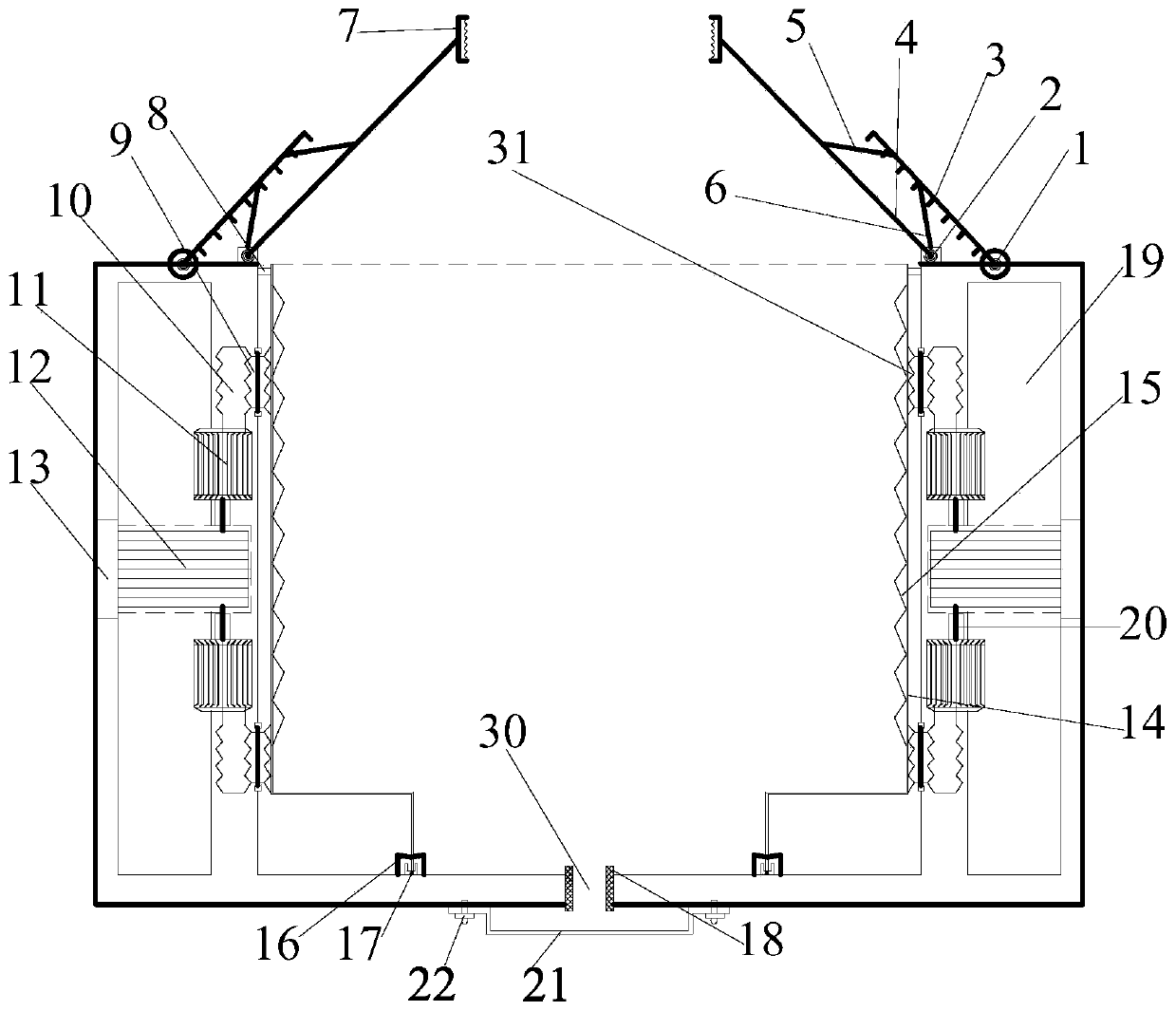

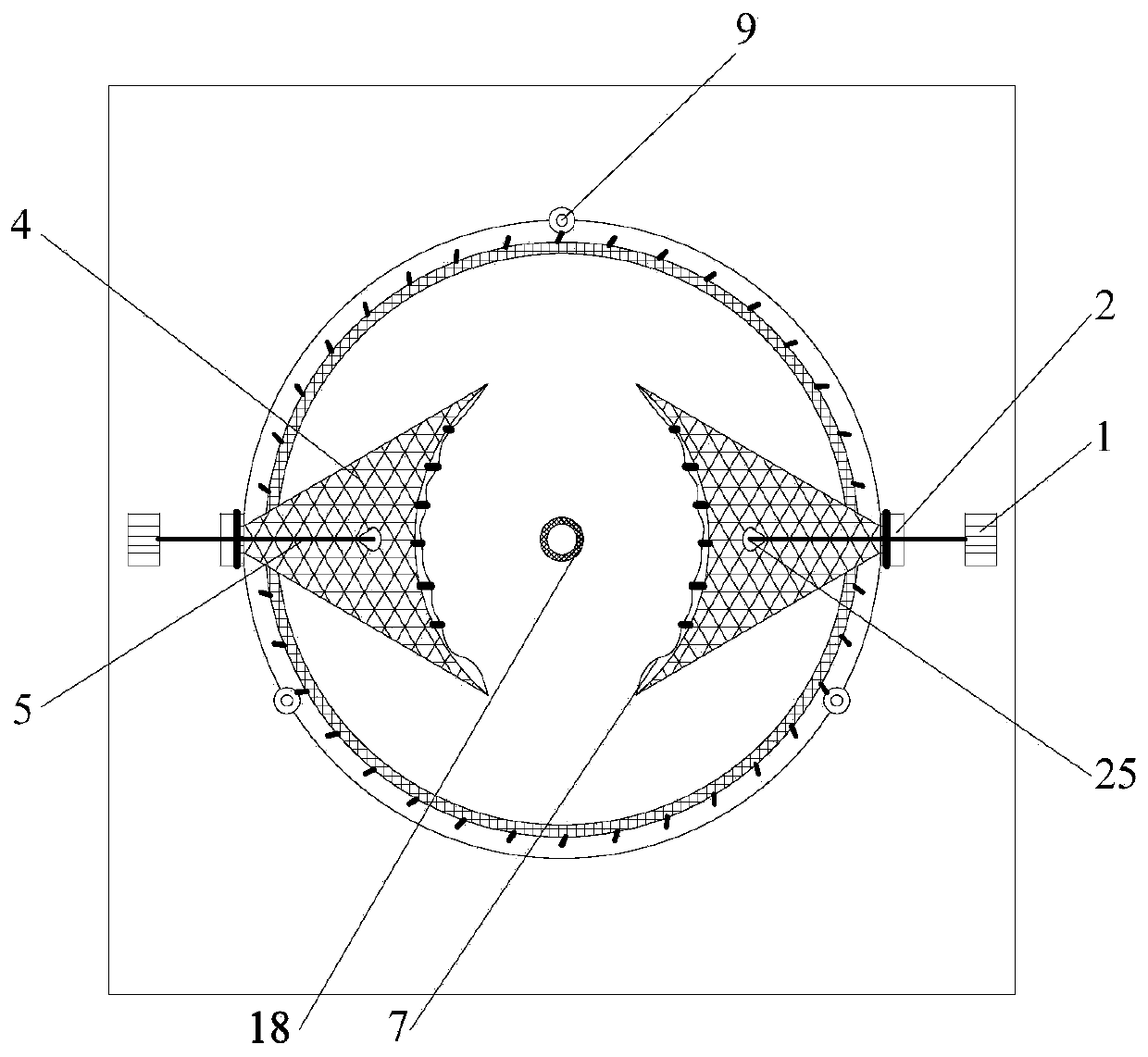

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0042] like Figure 1-Figure 6 As shown, the technical solution adopted by the present invention to achieve the above object is a method for pre-tightening the installation of microseismic sensors for underground bolts in coal mines. It is characterized in that the device used includes several units: explosion-proof casing 19, internal rotation 14. Energy supply accessories, fastening pliers, each unit is composed of several accessories.

[0043] The explosion-proof casing 19 described therein includes a power supply card slot 13, a casing transmission gear 9, a roller sleeve 26, a roller shaft 27, a slide rail 17, a ring pad 18, and a back cover 21, and the base of the casing has bolt holes 30 , the shell is a steel bearing structure with a cylindrical hollow in the middle, the power supply card slot 13 is located on the outer wall, the transmission gear 9 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com