Preparation method of enamel surface coatings with hydrophobic effect

A technology of surface coating and enamel, which is applied in the field of preparation of enamel surface coating, to achieve strong hydrophobic effect, long effective time of hydrophobicity, excellent chemical stability and protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

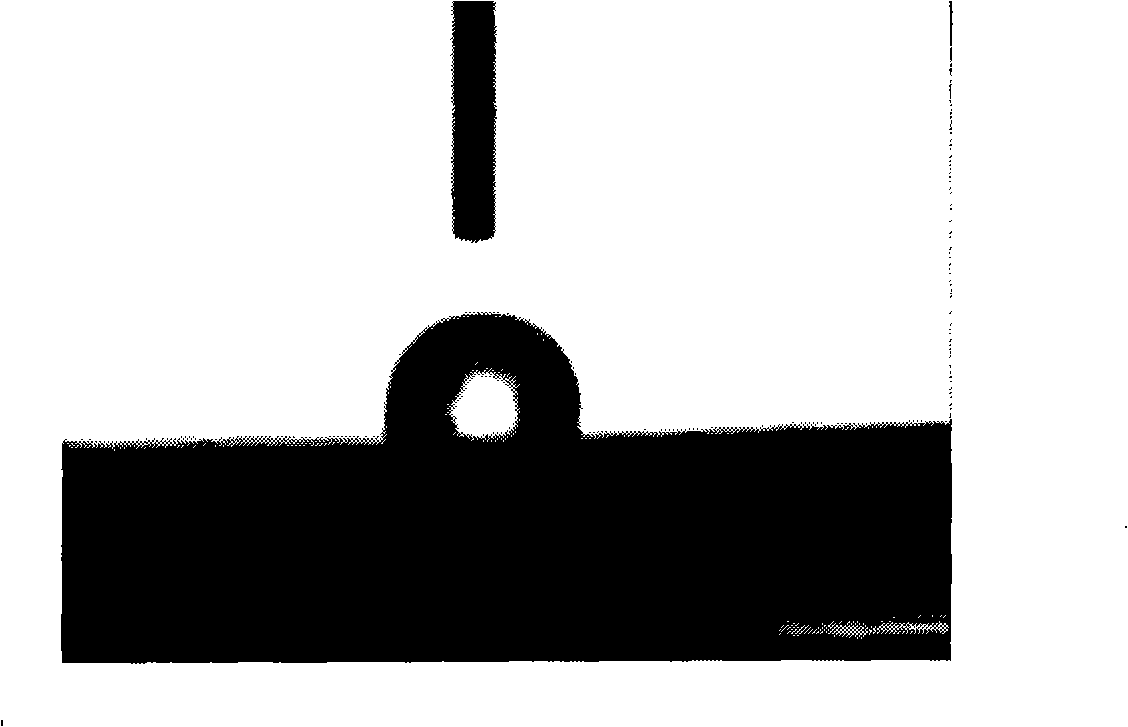

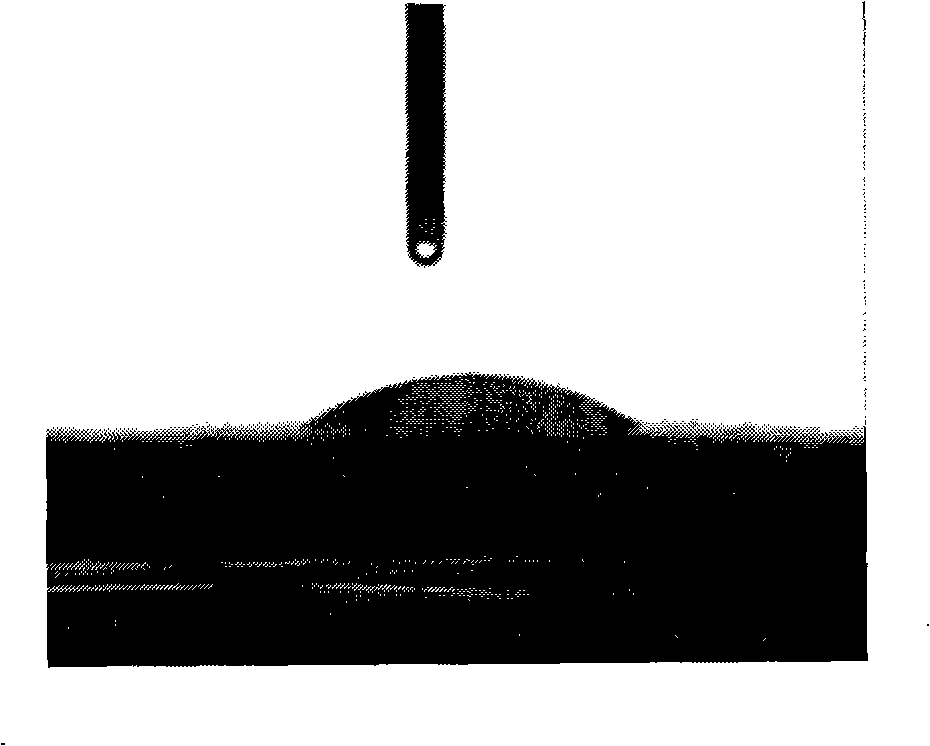

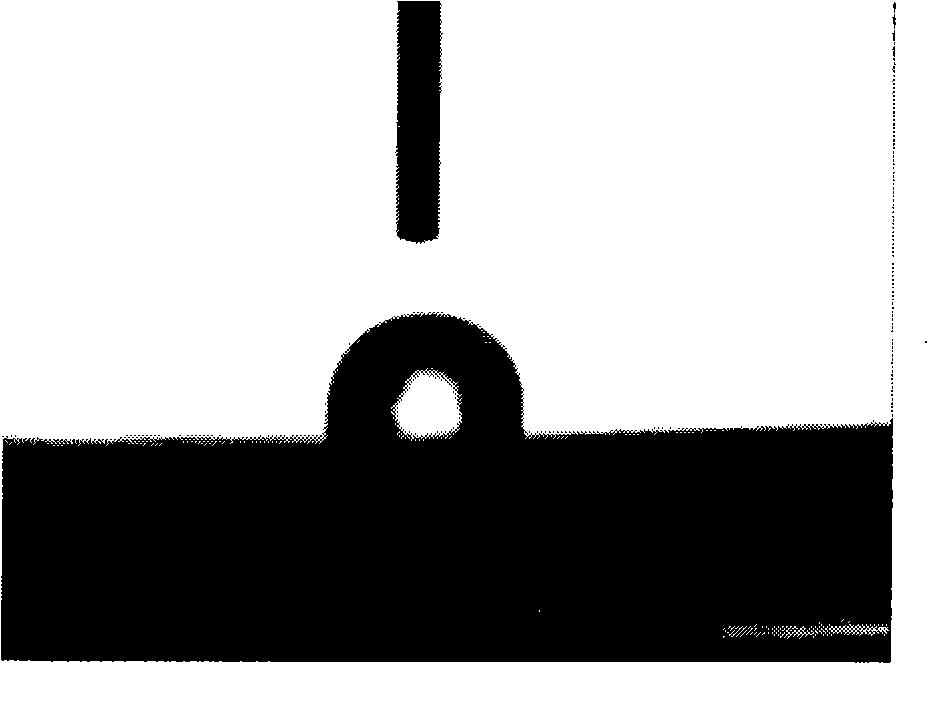

Image

Examples

Embodiment 1

[0026] (1) Wash the ordinary enamel plate with deionized water for 30 minutes, and place it in an oven at 80°C to dry;

[0027] (2) Preparation of the sol, Si(OC 2 h 5 ) 4 , C 2 h 5 OH, H 2 O, HCl, and DMF were mixed, stirred with a magnetic stirrer at room temperature for 1 hour, and then slowly added dimethylchlorosilane (DMCS) prepared to modify the surface of the sol. The volume fraction of DMCS was controlled to be 2.5%, and the pH value was 1.5;

[0028] (3) The sol formed after hydrolysis is aged at room temperature for 9 days, and before complete gelation, the solution viscosity reaches the optimum film coating time;

[0029] (4) Using the dip coating method, the enamel substrate in step (1) is immersed in the sol, and after one minute, it is pulled vertically at a speed of 0.5cm / s, so that the DMCS-modified silica colloidal solution is evenly coated Cover the surface of the enamel substrate, then keep it warm at 60°C for 20 hours, and cool slowly to make an ena...

Embodiment 2

[0032] (1) Wash the ordinary enamel plate with deionized water for 30 minutes, and place it in an oven at 80°C to dry;

[0033] (2) Preparation of sol, the Si(OC with a molar ratio of 2:4:4:0.3:2 2 h 5 ) 4 , C 2 h 5 OH, H 2 O, HCl, and DMF were mixed, and after stirring with a magnetic stirrer at room temperature for 1 hour, slowly added trimethylchlorosilane (TMCS) prepared to modify the surface of the sol, controlling the volume fraction of DMCS to be 5%, and the pH value to be 3;

[0034] (3) The sol formed after hydrolysis is aged at room temperature for 10 days, and before complete gelation, the solution viscosity reaches the optimum film coating time;

[0035] (4) Dip the enamel substrate in step (1) into the sol by dipping, and pull it vertically at a speed of 0.5cm / s after one minute, so that the TMCS-modified silica colloidal solution is evenly coated Cover the surface of the enamel substrate, then keep it warm at 80°C for 10 hours, and cool slowly to make an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com