Device for producing ductile material using metal sheet

A technology of metal flakes and extended materials, which is applied in metal processing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

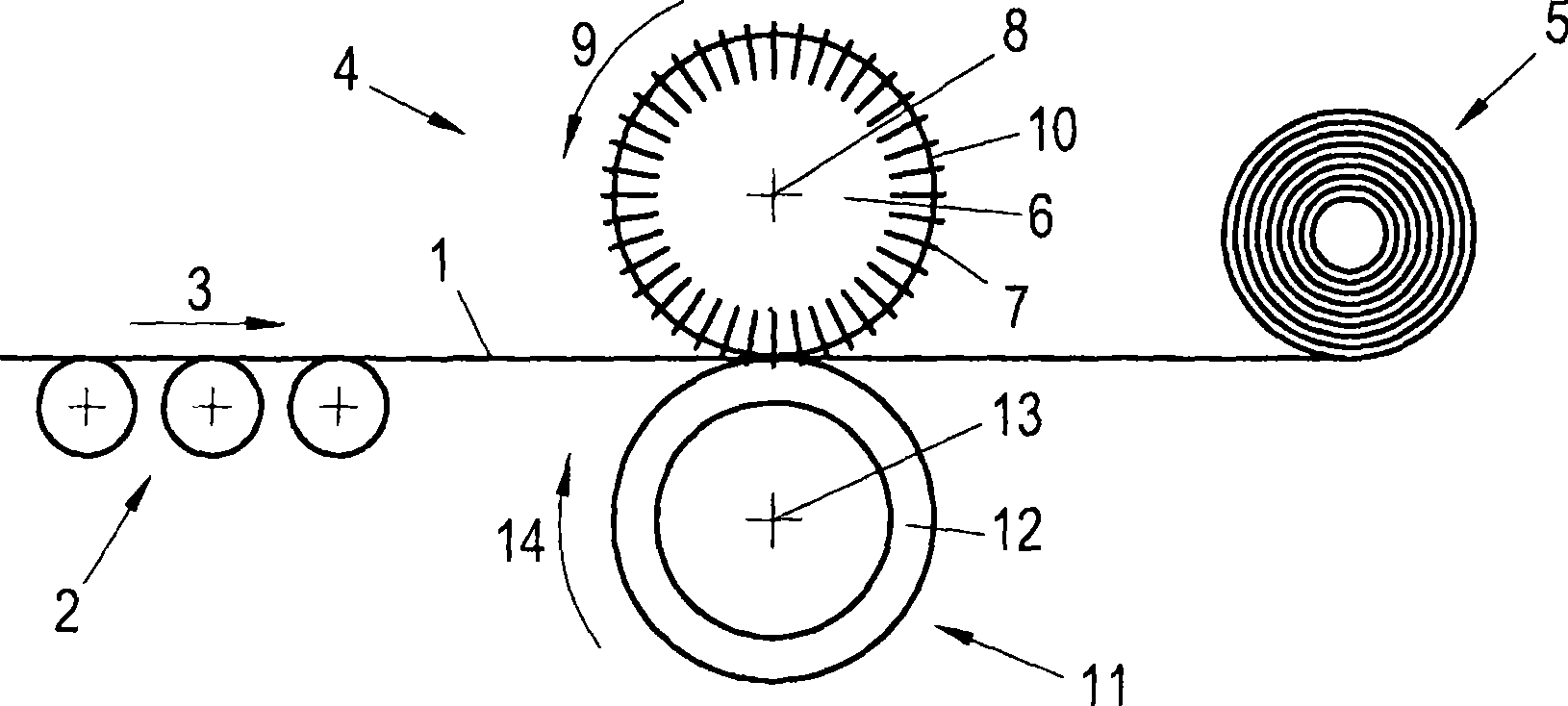

[0021] figure 1 shows generally a plant for the production of expanded material, in which sheet metal 1 is supplied in the direction of arrow 3 to a cutting device indicated generally at 4 by means of a feed device, for example constituted by a conveyor device 2 . For further processing or processing, after passing through the cutting device 4 , the expanded material 1 processed with cuts or slits or perforations in the cutting device 4 is wound up in a subsequent stretching and / or winding device 5 .

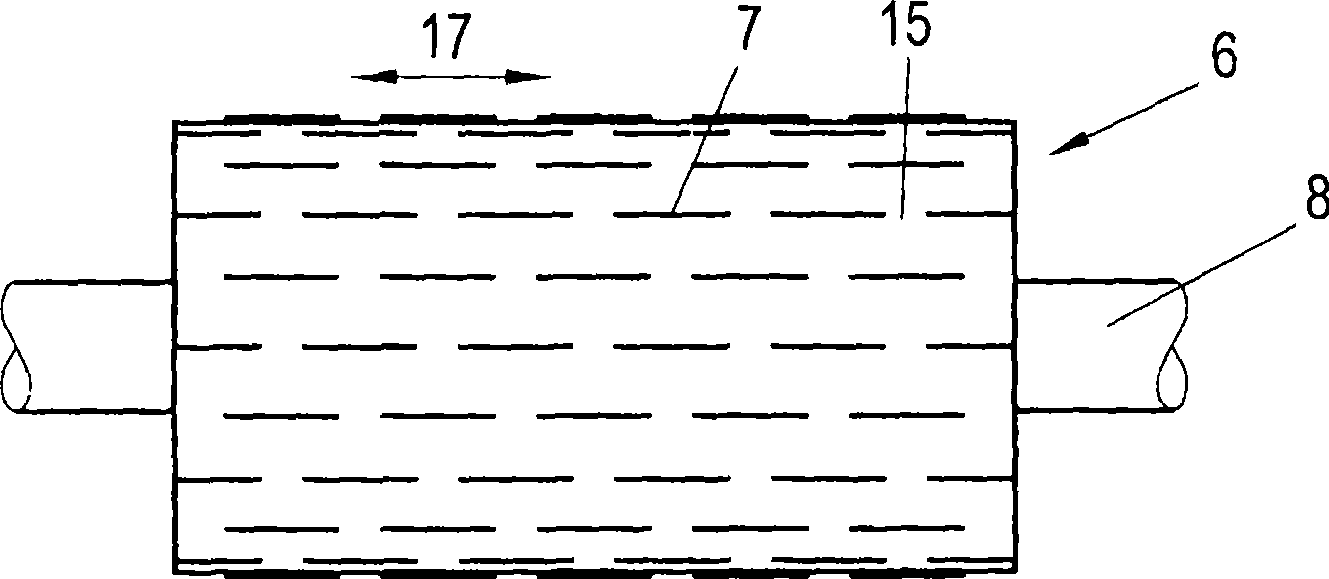

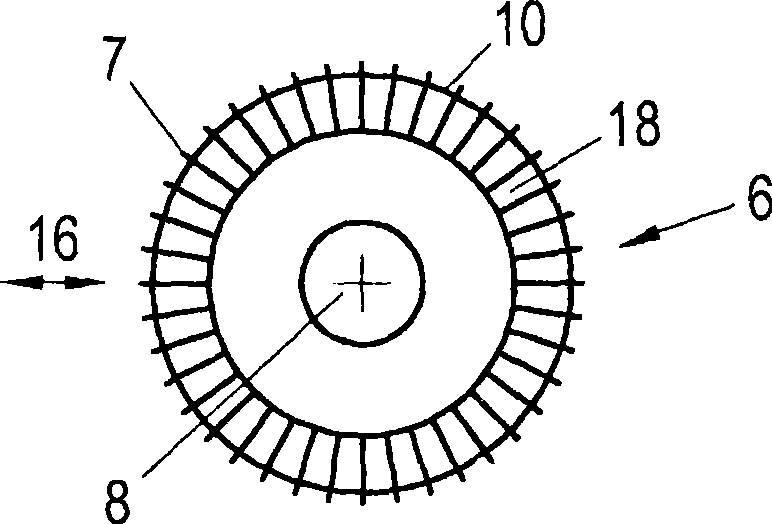

[0022] Such as figure 1 As shown, cutting device 1 comprises a roll 6, is provided with the blade or cutter 7 that is substantially equidistant from each other schematically shown in many figures on the whole circumference of roll 6, and roll 6 can rotate around axis 8 along the direction of arrow 9, In order to make a plurality of cuts or slits or perforations in the sheet metal or raw material 1 as it passes through the material by means of blades or cutters 7 protruding from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com