Divert ball joint assembly

A steering ball and assembly technology, applied in steering mechanism, steering rod, transportation and packaging, etc., can solve the problem of shortening the service life of the steering ball joint assembly, affecting the service life of the steering ball joint assembly, and manufacturing the steering ball joint assembly. The problem of high cost, to achieve the effect of improving the safety index, good elastic performance, and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

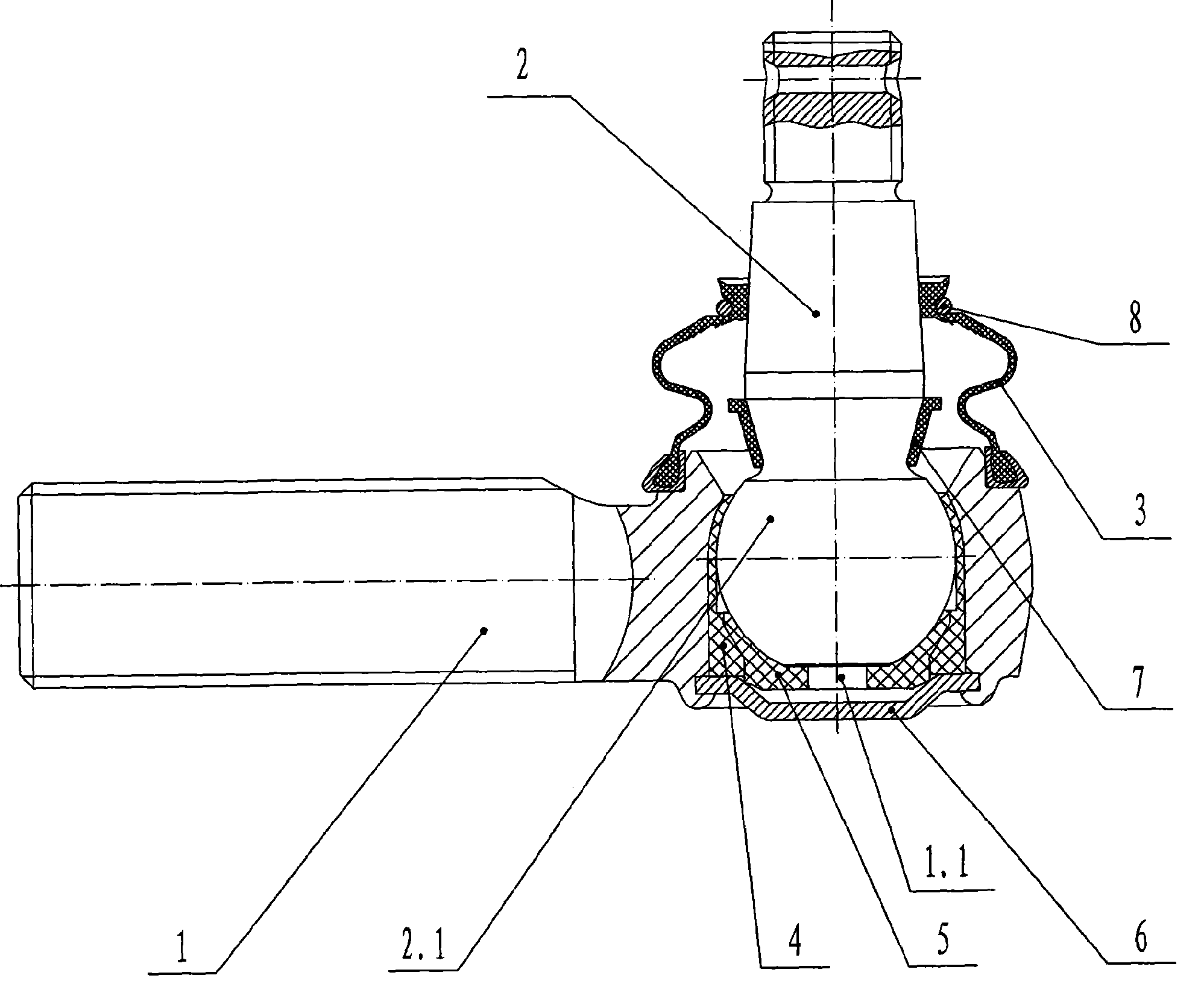

[0012] As shown in the drawings, in this specific embodiment, the present invention includes a ball seat 1, a ball stud 2, a dust cover 3, a wear-resistant bushing 4, an elastic bushing 5, and a ball seat 1 connected to the bottom for sealing. The gasket 6 that holds the ball head hole 1.1; the upper part of the dust cover 3 is fastened on the taper part of the ball stud 2 through the collar 7, and the lower part is fastened in the groove on the upper part of the ball seat 1; The ball head portion 2.1 of the ball stud pin 2 is located in the ball head hole 1.1 on the ball seat 1; the wear-resistant bushing 4 is connected to the entire inner wall of the ball head hole 1.1; the elastic bushing 5 is connected to the Below the inner wall of the wear-resistant bushing 4; the upper middle part of the ball head part 2.1 is in close contact with the wear-res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com