Aluminum cell bus-bar collocation structure including external compensation

An external compensation, aluminum electrolytic cell technology, applied in the field of current supply devices, can solve problems such as uneconomical, difficult to ensure accuracy, and unsatisfactory magnetic field compensation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

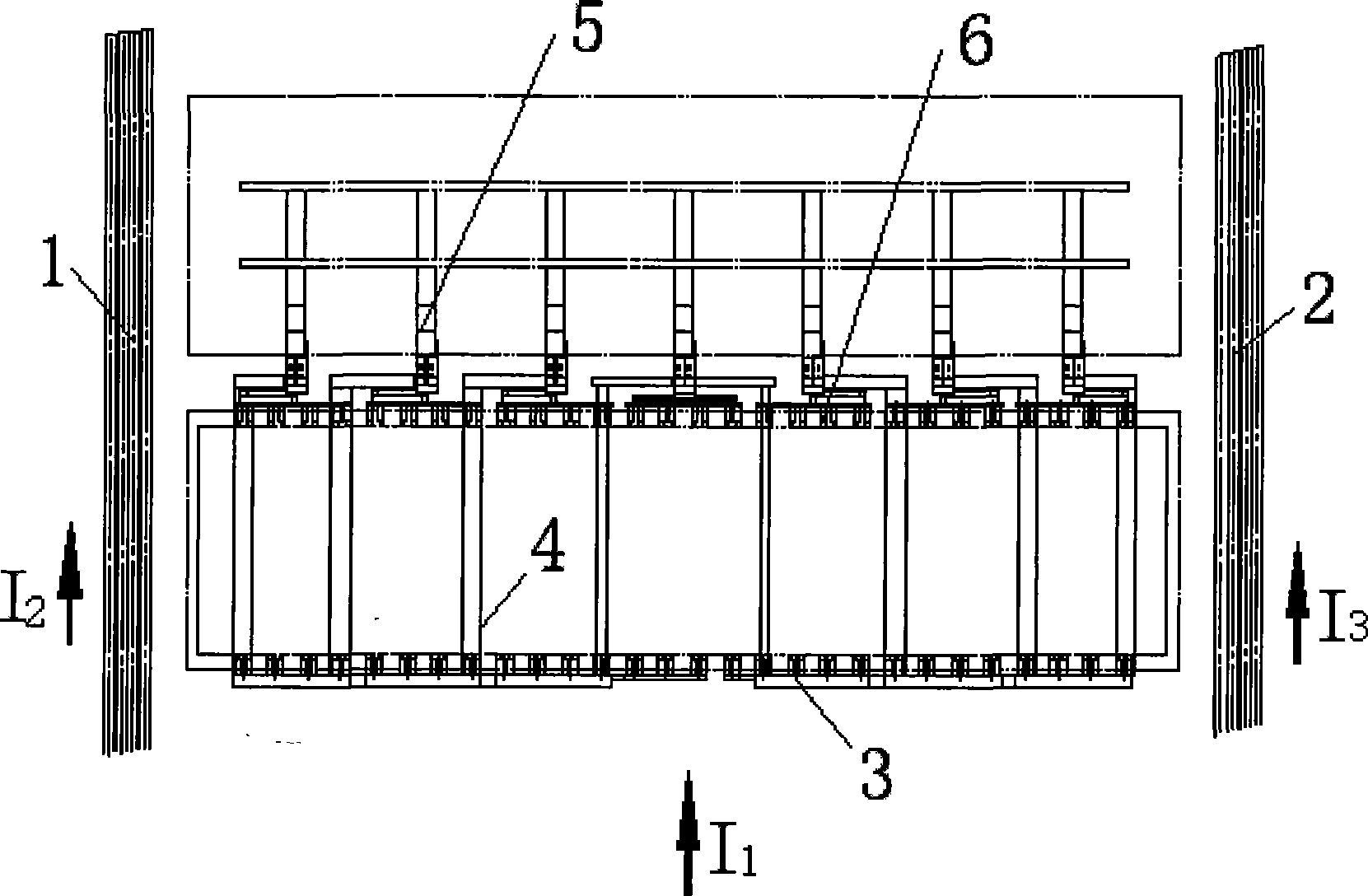

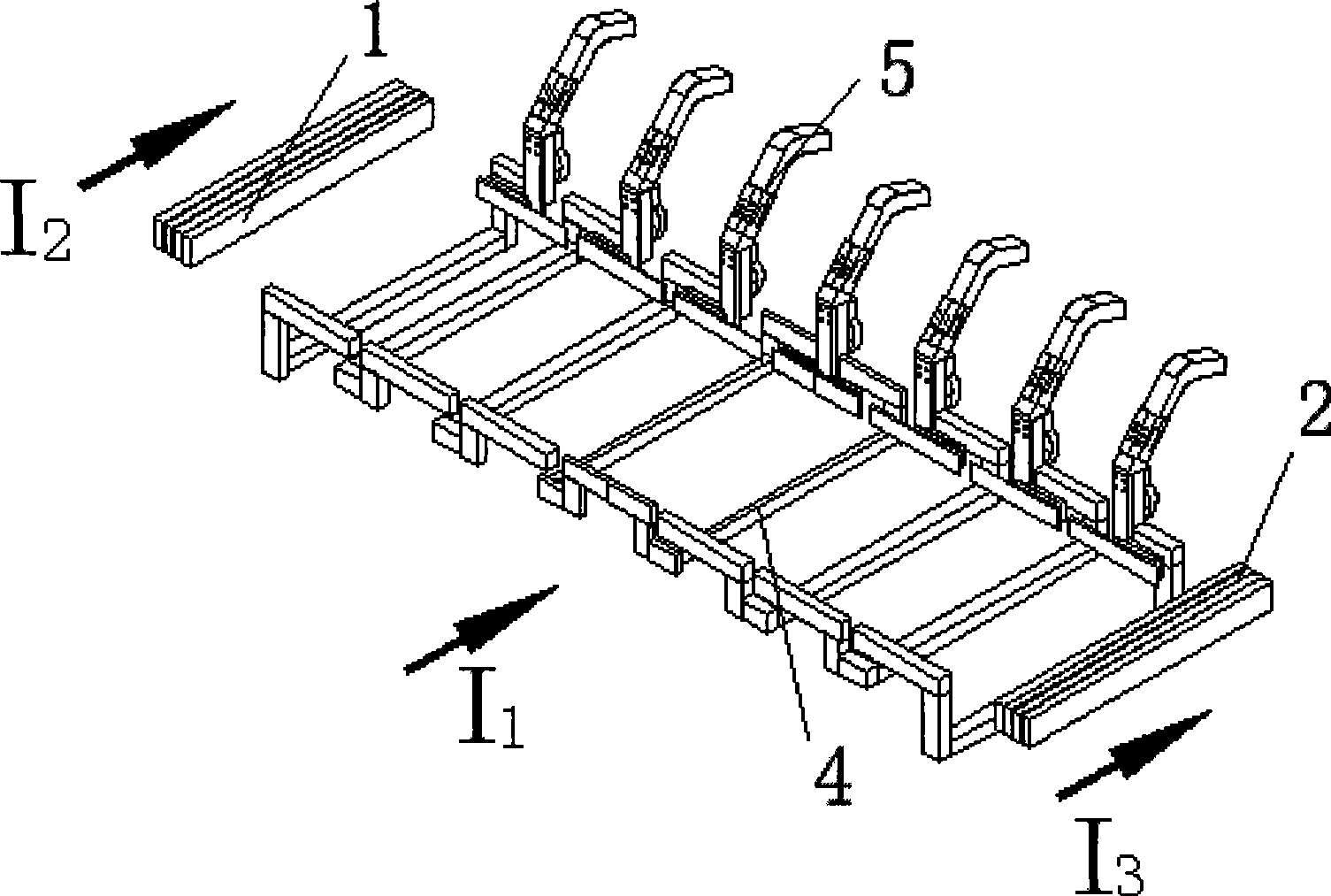

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] In the existing aluminum electrolytic cell, the main function of the cathode bus bar is to supply power to the electrolytic cell, and also undertake the functions of correcting the magnetic field of the current cell and compensating the magnetic field of adjacent cells. However, with the increase of series current, the influence of the magnetic field distribution generated by the current-carrying busbar and melt current on the stability of the production and operation of the cell becomes more and more prominent, and the self-compensation of the cathode busbar alone cannot guarantee The basic requirement is that the vertical magnetic field and its horizontal gradient value in the melt are small and uniform, and the disturbance hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com