Stamping equipment life cycle management cloud platform and using method

A stamping equipment and life cycle technology, applied in the field of stamping equipment life cycle management cloud platform, can solve problems such as inability to perform comparative analysis, difficulty in sharing data without obstacles, inability to verify and predict the time node of equipment failures in advance, etc. , to achieve the effect of prolonging the effective working time and efficiency of the equipment, good equipment management and maintenance effect, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

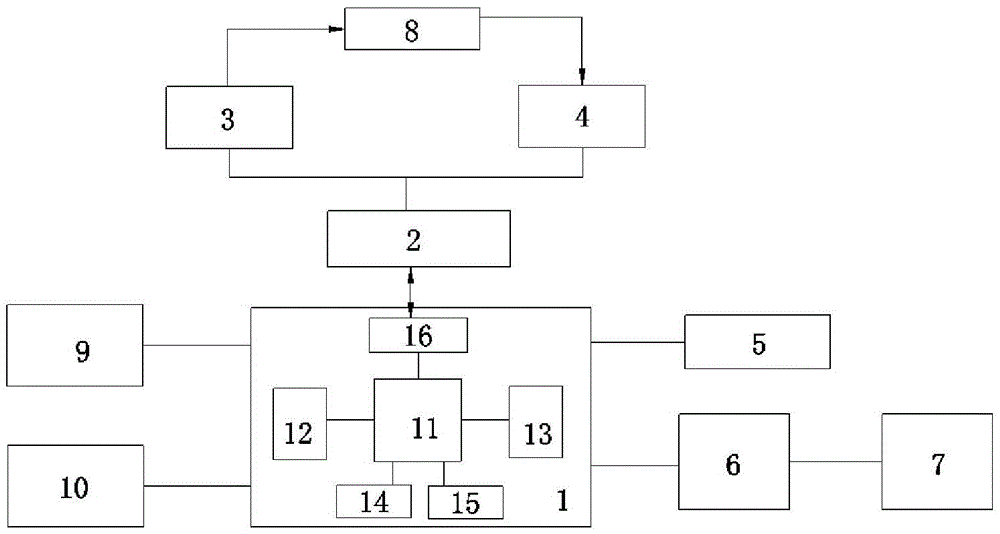

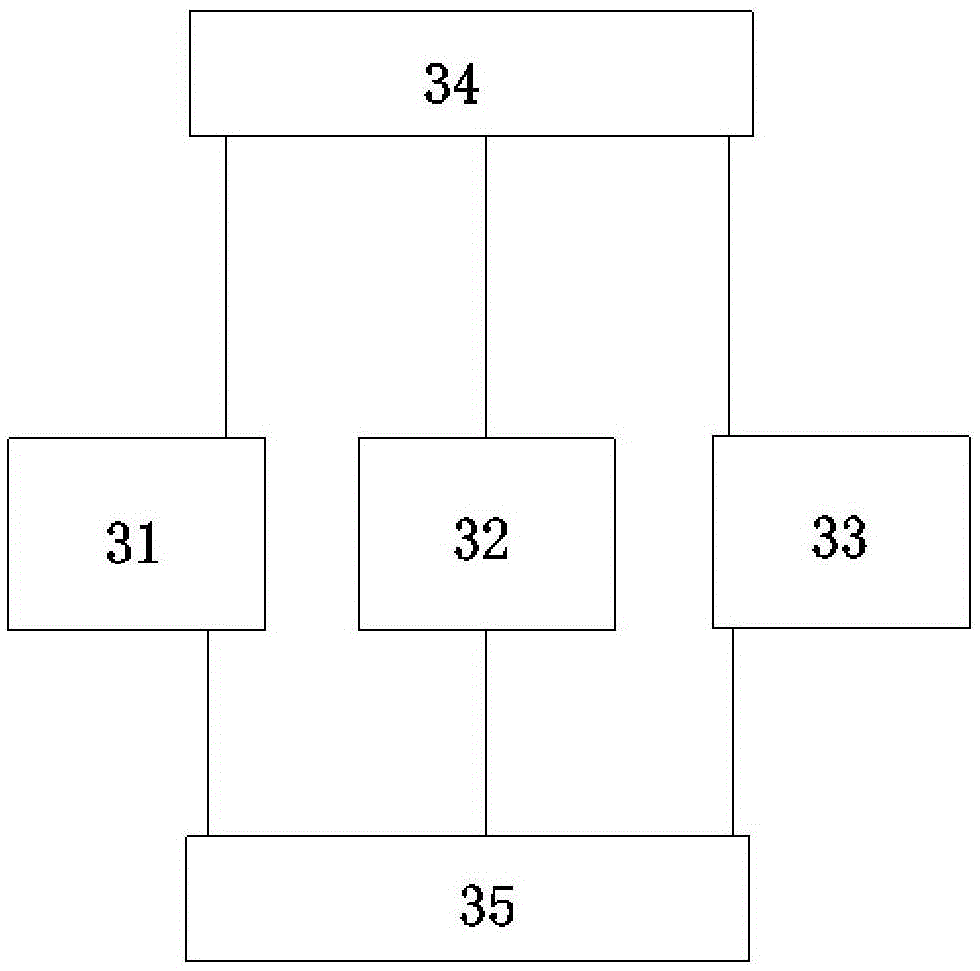

[0021] like figure 1 , figure 2 As shown, a stamping equipment life cycle management cloud platform and its use method, including cloud platform 1, cloud transmission module 2, on-site intelligent controller 3, on-site data collector 4, stamping equipment management module 5, wireless communication module 6 and intelligent Terminal 7, the cloud platform 1 is respectively connected to the on-site intelligent controller 3 and the on-site data collector 4 through the cloud transmission module 2, and the on-site intelligent controller 3 and the on-site data collector 4 are respectively connected to Stamping equipment 8, on-site data collector 4 can directly collect real-time operating parameters and safety parameters of the stamping equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com