Self-cleaning type water tanks

A water tank and water storage technology, which is applied in the direction of water saving, water supply device, water supply tank configuration, etc., can solve the problems of cleaning brush pollution, time-consuming and labor-intensive work, poor reliability, etc., to achieve improved cleaning speed, good cleaning effect, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

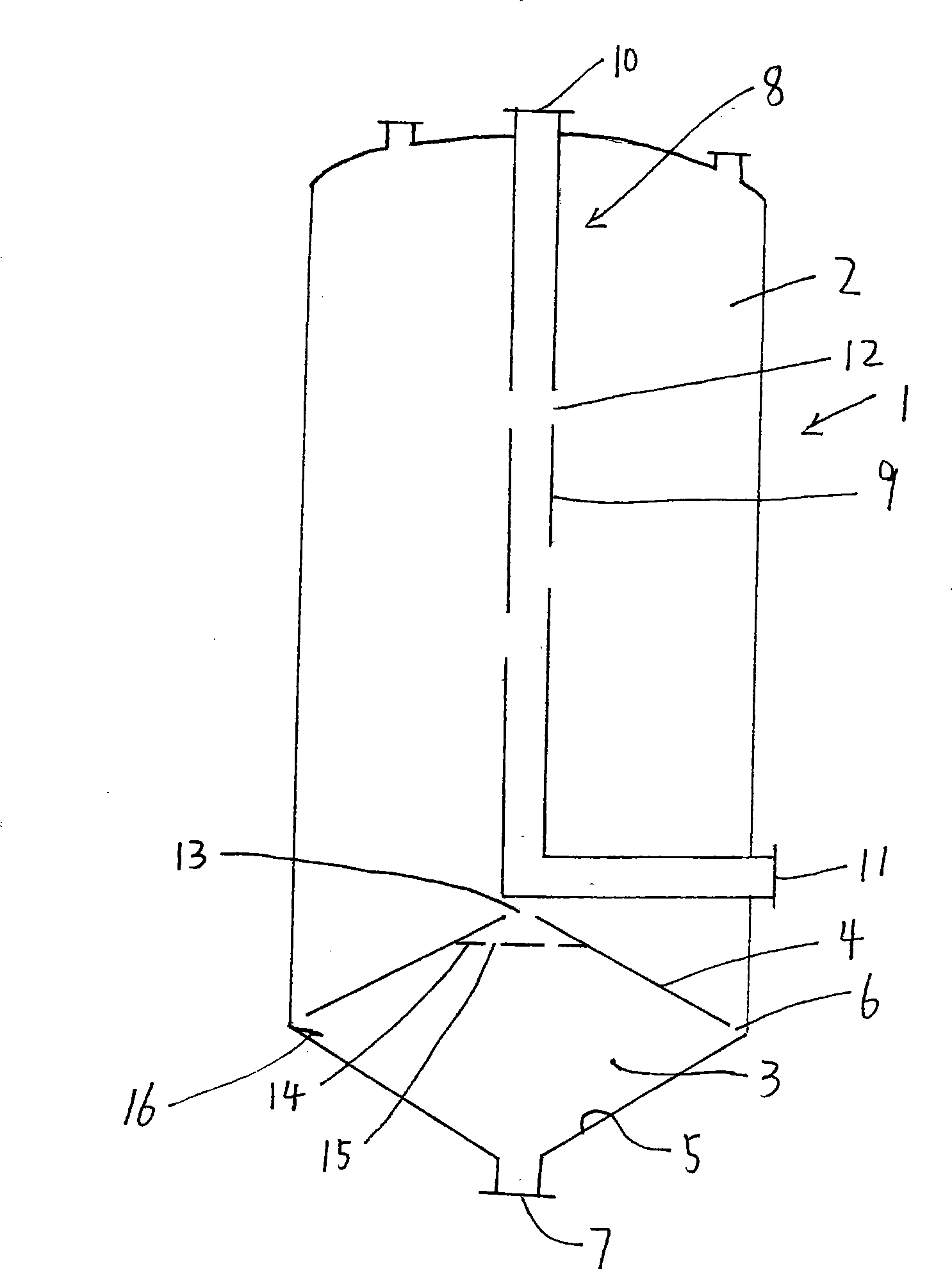

[0012] Embodiment: a self-cleaning water tank, the box body 1 is vertically arranged, the box body is composed of a water storage area 2 and a sedimentation area 3, the sedimentation area is below the water storage area, and the water storage area and the sedimentation area are formed by a cone-shaped partition 4 Separate (such that the water storage area and the sedimentation area do not interfere with each other and facilitate the sediment in the water to slide down to the sedimentation area along the cone surface), the bottom 5 of the sedimentation area is in the shape of an inverted cone (the longitudinal center section of the entire sedimentation area is rhombus), and the There is a certain gap 6 between the peripheral edge and the inner wall of the box (it is the first channel between the water storage area and the sedimentation area), the center of the bottom of the sedimentation area (for the inverted cone top) is provided with a cleaning port 7, and the water storage ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com