Inclined shaft type hydraulic transformer and voltage transformation method

A technology of hydraulic transformers and inclined shafts, which is applied in the direction of physical quantity changers, machines/engines, liquid variable capacity machines, etc. It can solve the problems of loss of pressure transformation ability, reduction of pressure transformation efficiency, and increase of thrust, so as to expand the scope of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

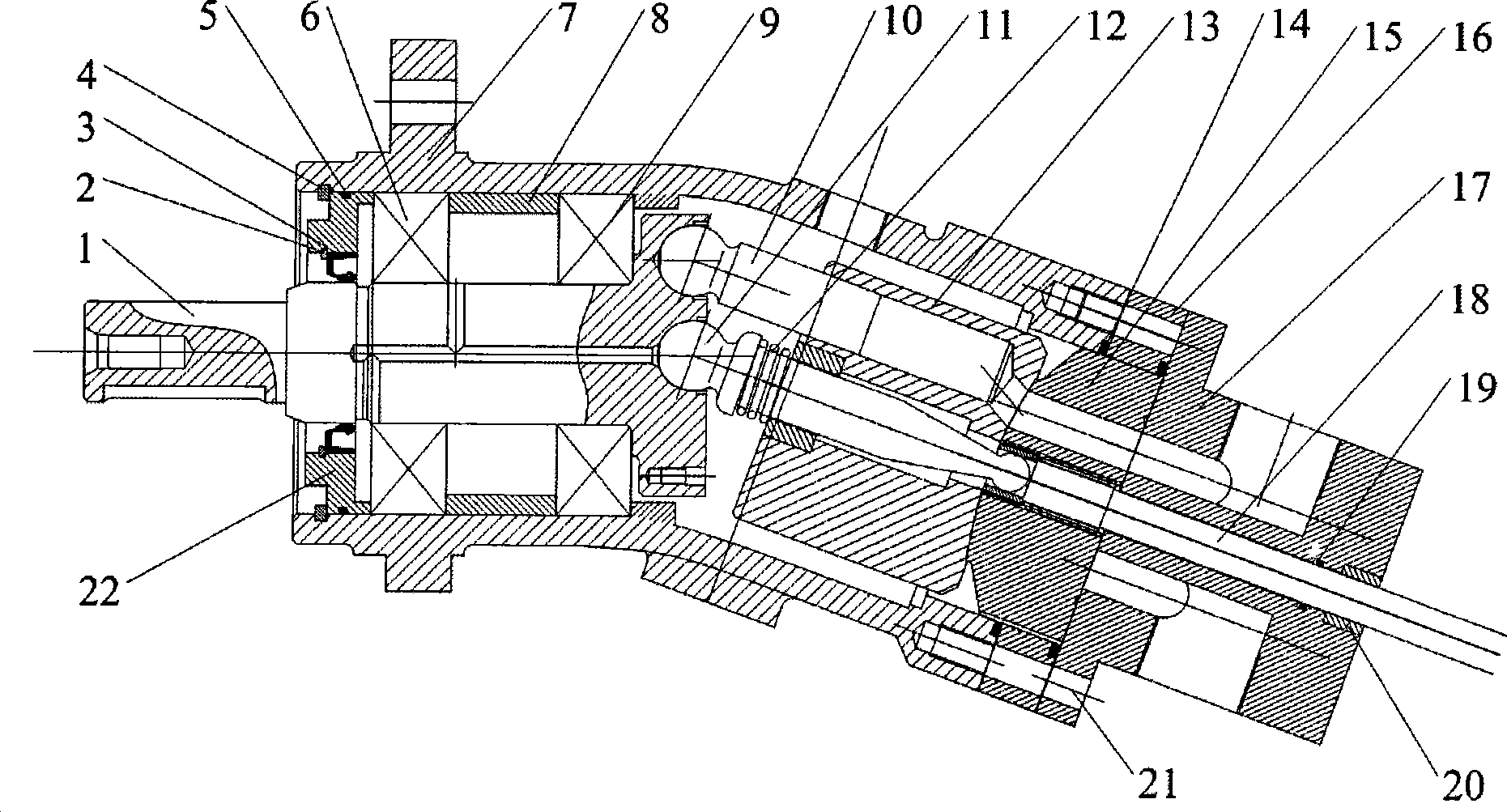

[0020] exist figure 1 Among them, a transition plate (16) is designed between the back cover (17) and the housing (7) of the hydraulic transformer, so that the thickness of the valve plate (15) can be increased, so that the valve plate (15) and the rotating rod (18) The spline connection between them can achieve sufficient strength. The rear end of the turning rod (18) can be connected with a rotary actuator or adjusted manually to control the input and output pressure and flow of the hydraulic transformer; parts (1-13) and parts (22) can be borrowed from the existing ramp Existing components for shaft pumps / motors.

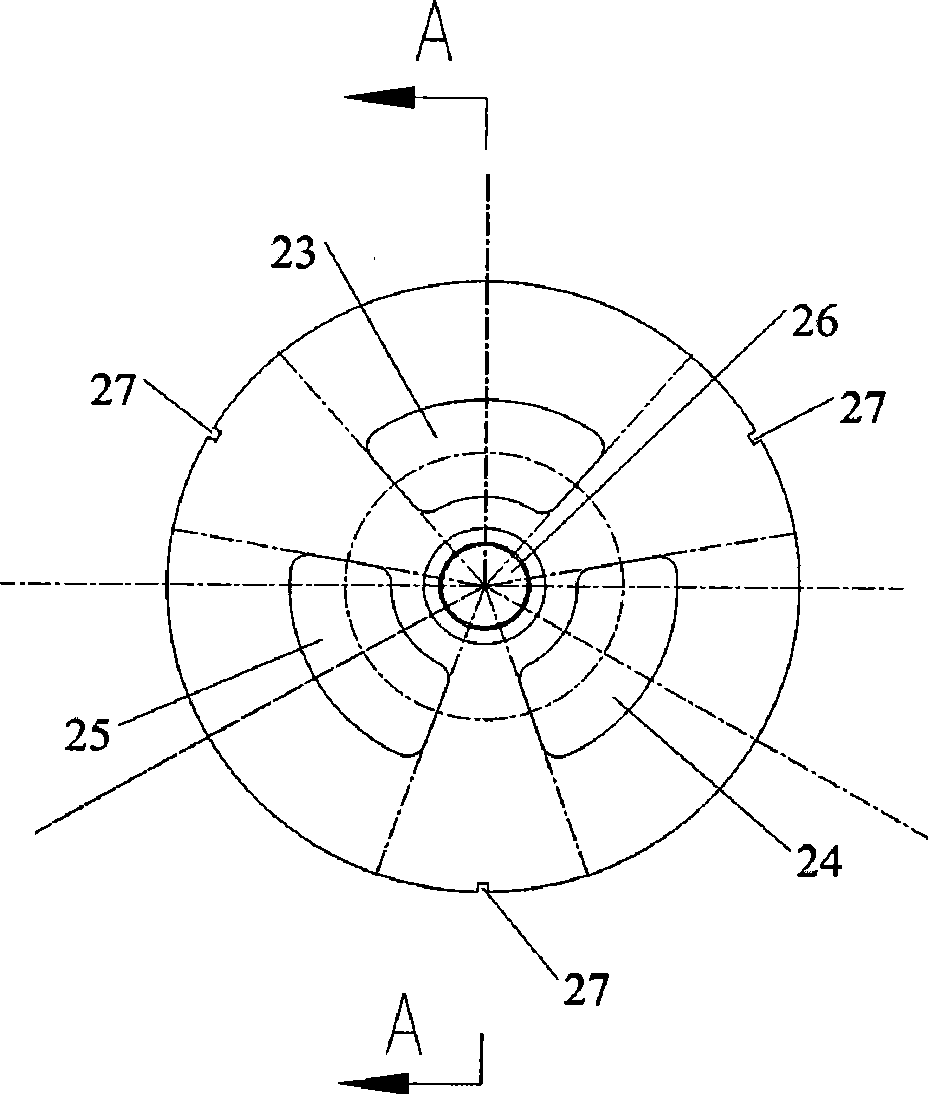

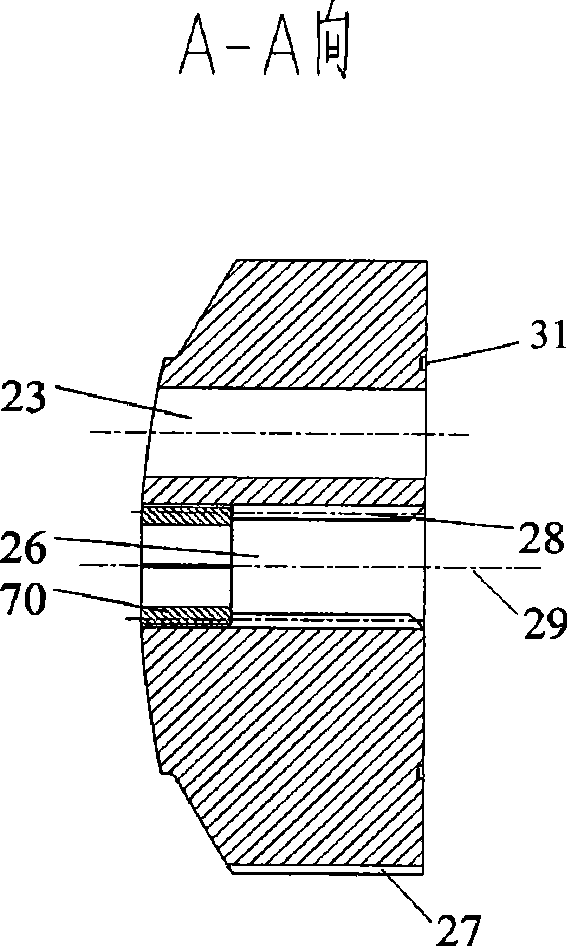

[0021] In Fig. 2, 3, 7, there are three distribution notches (23), (24), (25) evenly distributed on the distribution plate (15), used for input or output pressure oil; The center of the center is designed with a center hole (26), and the first half of the center hole (26) is pressed into the copper sleeve (70) for positioning with the ball head of the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com