Bidirectional guide stop valve

A stop valve, two-way technology, applied in the field of two-way diversion stop valve, can solve frequent problems, achieve cost reduction, and solve the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

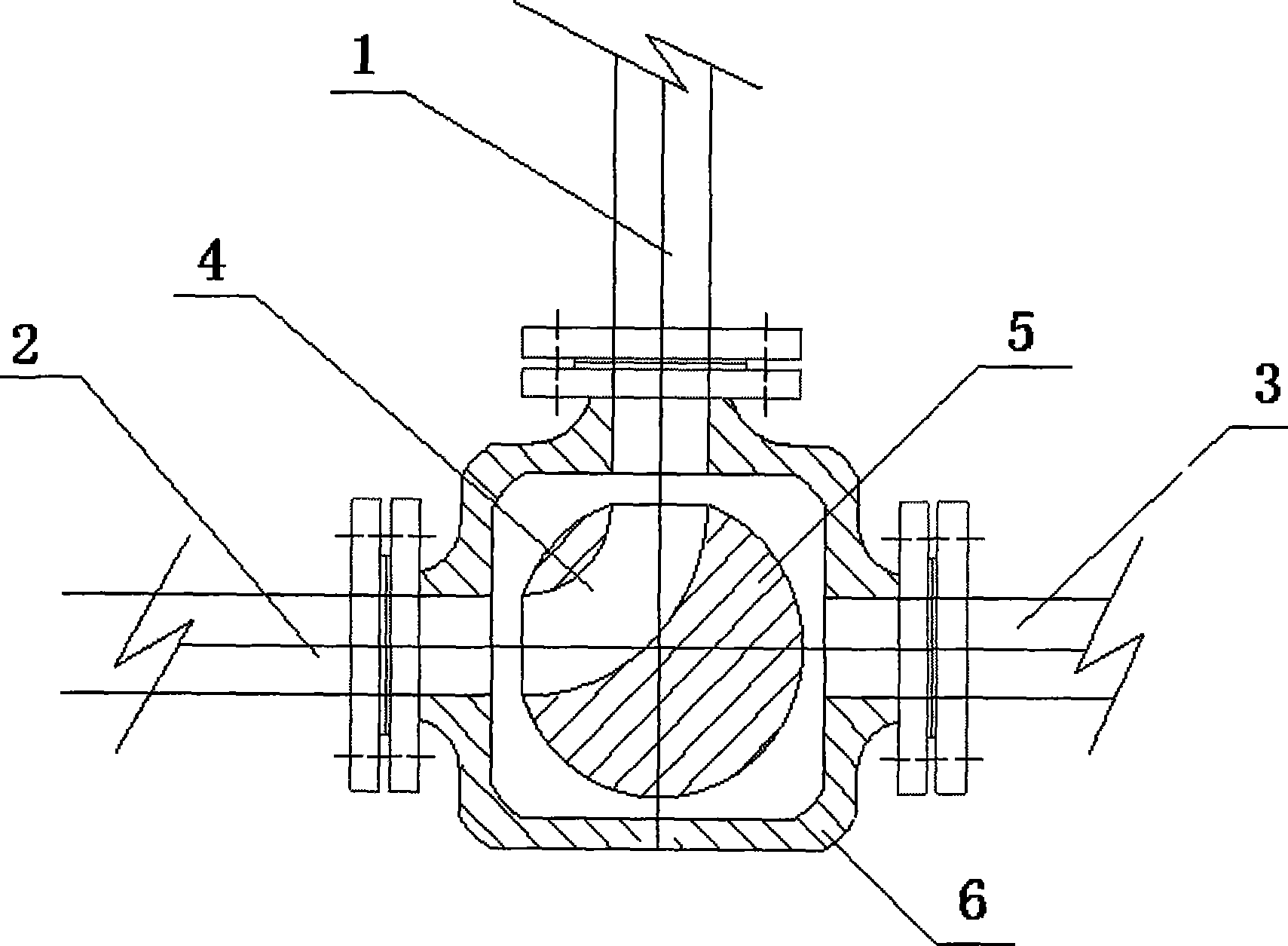

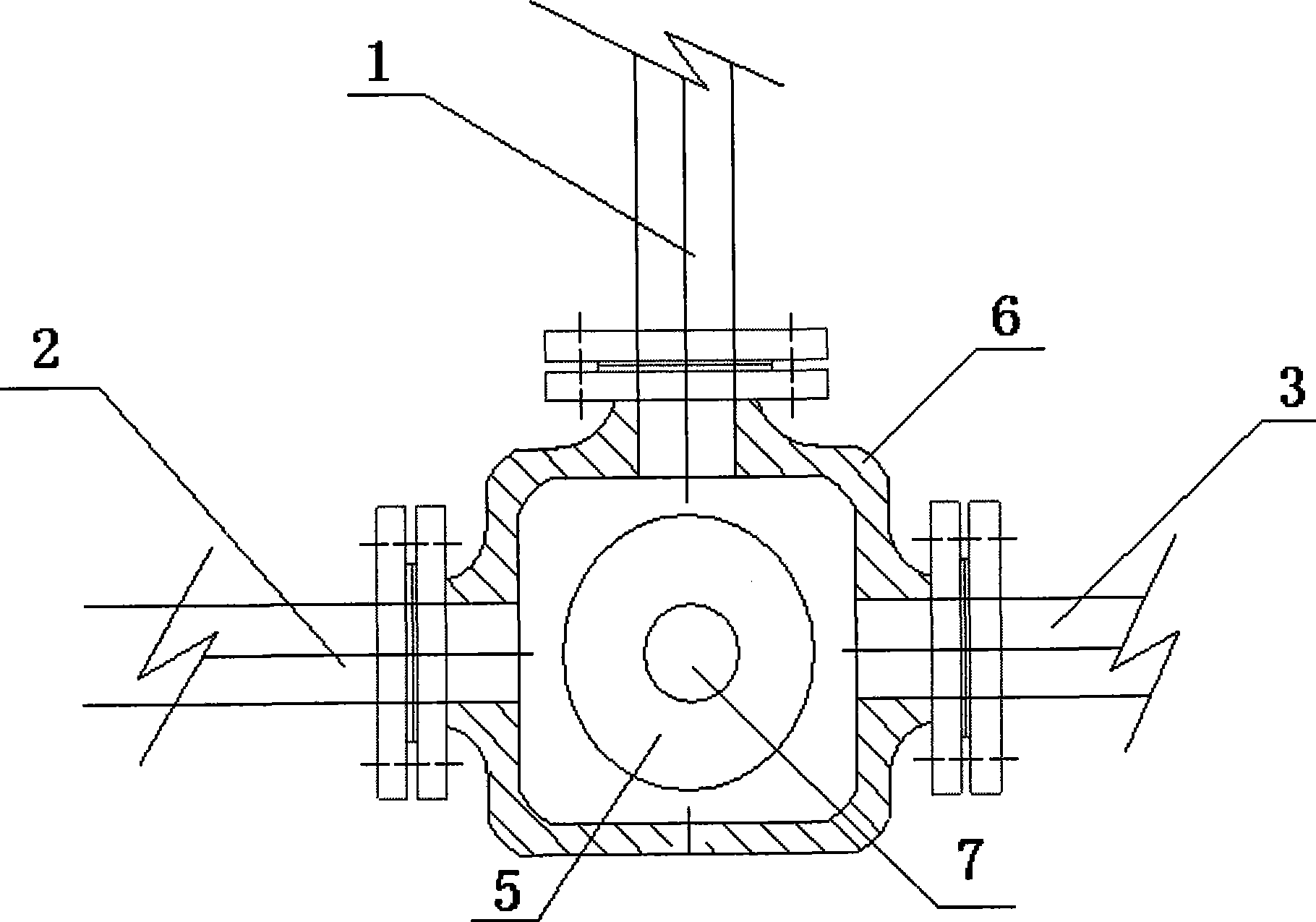

[0013] like figure 1 and figure 2 As shown, the valve body 6 has three ports in different directions, the three ports are the upper port 1, the left port 2 and the right port 3 respectively, and the three ports communicate with the valve cavity respectively, the valve cavity is a spherical body, and the spherical cavity in the valve cavity slides A spherical spool 5 is mated and connected, and the spherical spool 5 has a bidirectional flow guide 4 and an axial drive shaft 7, the drive shaft 7 and the bidirectional flow guide 4 form 90 degrees, and the rotation of the drive shaft 7 can make the bidirectional flow guide 4 The openings at both ends are separated and communicated with the upper port 1 and the left port 2 or the upper port 1 and the right port 3, and the three ports can also be isolated from each other. The two-way guide channel 4 forms a 90-degree angle between the two openings, and the two openings are transitioned by a curve.

[0014] The specific operation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com