Quench machining tool with rapid mold changing device and thread opening limiting device

A limit device and quenching machine tool technology, applied in the field of quenching machine tools, can solve the problems of excessive changes in the amount of grinding wheel feed, small replacement space, long replacement time, etc., to improve processing efficiency and pass rate, convenient operation and control, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

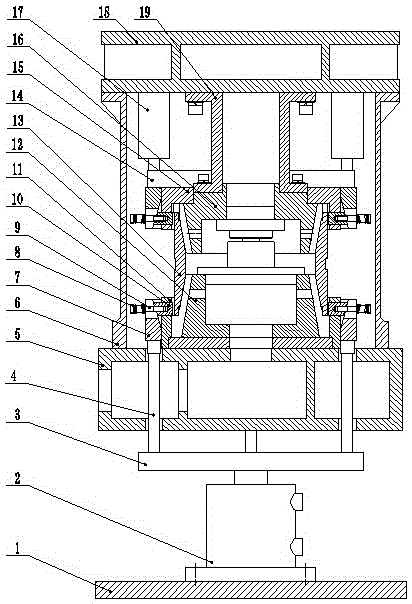

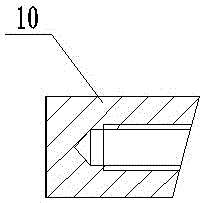

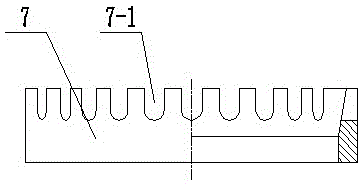

[0031] in the attached Figures 1 to 11 Among them, 1-main base, 2-lower mold cylinder, 3-lower pressure ring, 4-connecting rod, 5-working table, 6-quenching oil cover, 7-ring inner cone, 7-1-"U Shaped groove", 8-spring, 9-screw, 10-limiting block, 11-lower limiting block guide seat, 11-1-limiting block guide hole, 12-lower mold, 13-workpiece, 14-upper pressure ring , 15 - upper limit block guide seat, 16 - upper mold, 17 - upper mold oil cylinder, 18 - moving beam, 19 - upper mold seat, 20 - mold handle, 21 - insert plate, 22 - guide seat, 23 - connecting rod , 24-hinge, 25-connecting plate, 26-mold quick change cylinder, 27-cylinder mounting plate, 28-long groove, 29-ring groove.

[0032] Such as figure 1 As shown, the lower mold cylinder 2 is installed on the main base 1, the lower end of the disc-shaped lower pressure ring 3 is connected with the piston rod in the lower mold cylinder, and the upper plane of the lower pressure ring is fixedly equipped with a connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com