Half-section geotechnical milling machine

A milling machine and geotechnical technology, which is applied in the field of half-section geotechnical milling machines, can solve the problems of induced earthquakes and landslides, low production efficiency, high energy consumption, etc., and achieves strong rock cutting ability and construction safety. Large, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the drawings and embodiments.

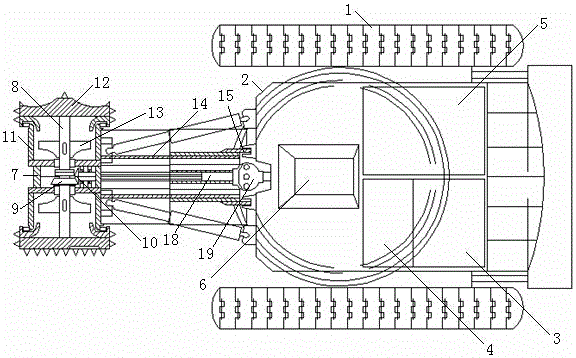

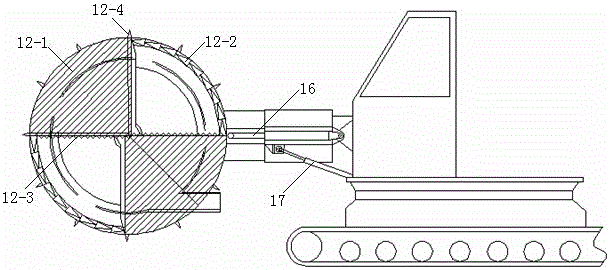

[0019] With reference to the drawings, this embodiment includes a crawler walking mechanism 1, a slewing support platform 2, and an engine 3, a gearbox 4, a hydraulic system 5 and a cab 6 on the platform, and a cylindrical bevel gear box 7, so The cylindrical bevel gear box 7 is provided with a driving main shaft 8, a bevel gear I9, and a bevel gear II10. The bevel gear I9 is mounted on the driving main shaft 8 and connected with the bevel gear II10; the cylindrical bevel gear box A volute-shaped silo 11 and a milling cutter disk 12 are respectively provided on both sides of the volute-shaped silo 11, a discharge port is provided at the bottom of the volute-shaped silo 11, and a turbine 13 is provided in the volute-shaped silo 11, so The turbine 13 is installed on the driving spindle 8, the milling cutter disc 12 is installed on the volute-shaped silo 11 through a bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com