Drilling tool

A tool and area technology, applied in the field of drilling tools, can solve the problems such as hindering the discharge of chips from the machining hole, frequent breakage of the drill bit, and deterioration of the hole position accuracy, and achieves the hole position accuracy and hole inner wall roughness, excellent practicability, Effect of rigidity and chip evacuation prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

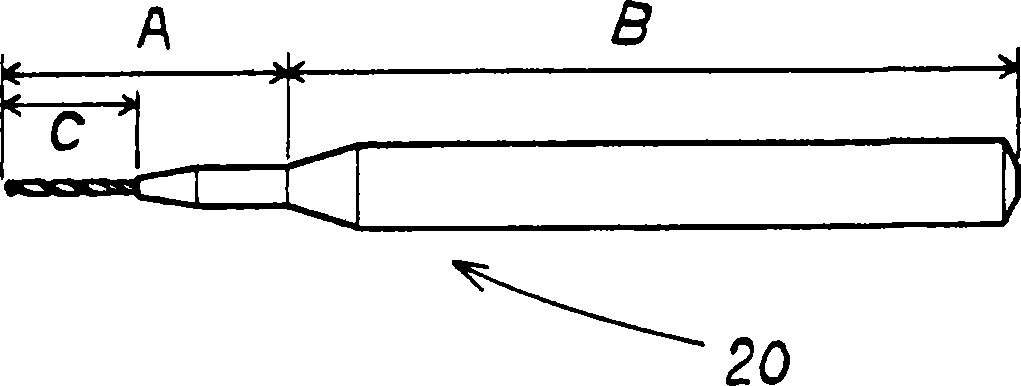

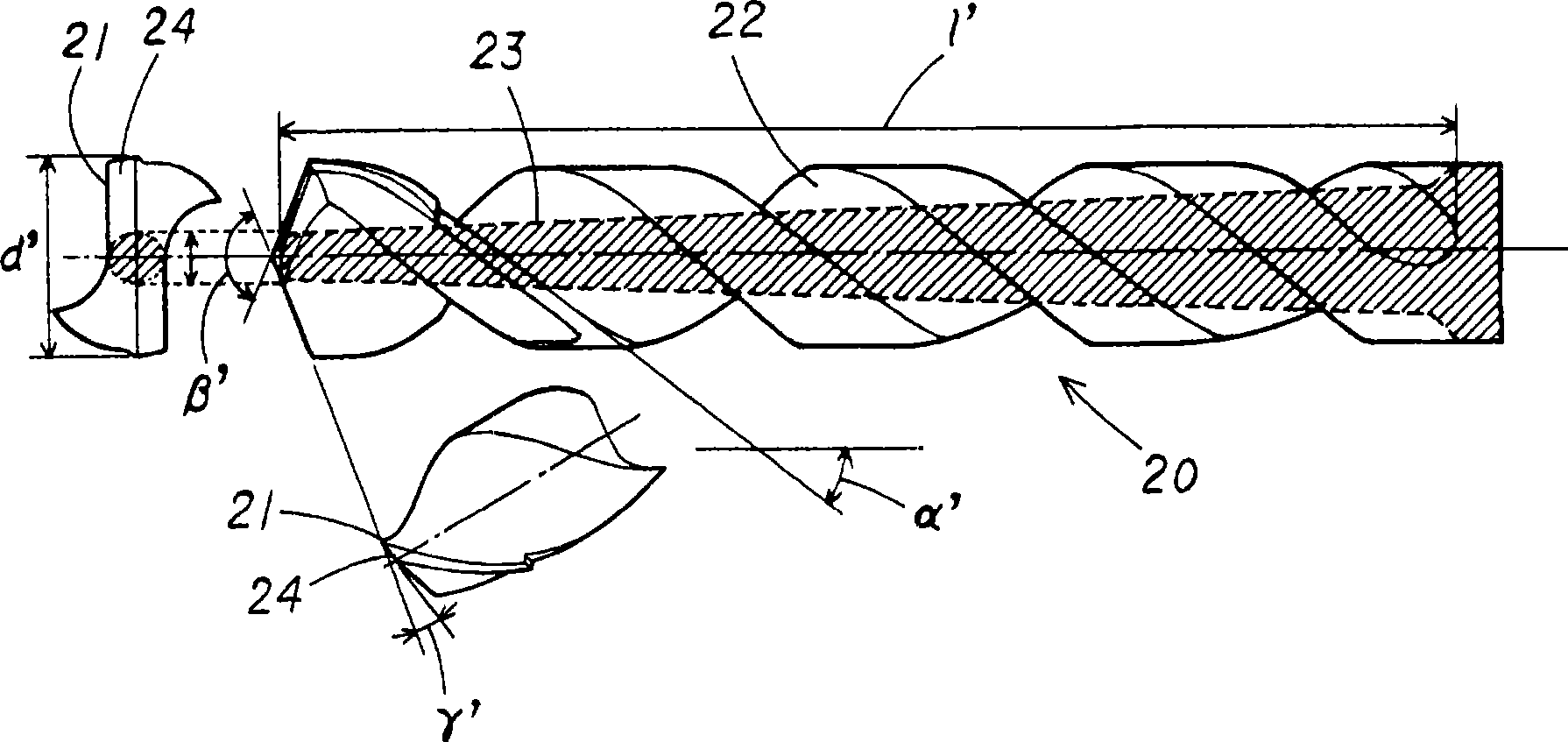

[0071] according to Figure 6 — Figure 12 Specific embodiments of the present invention will be described.

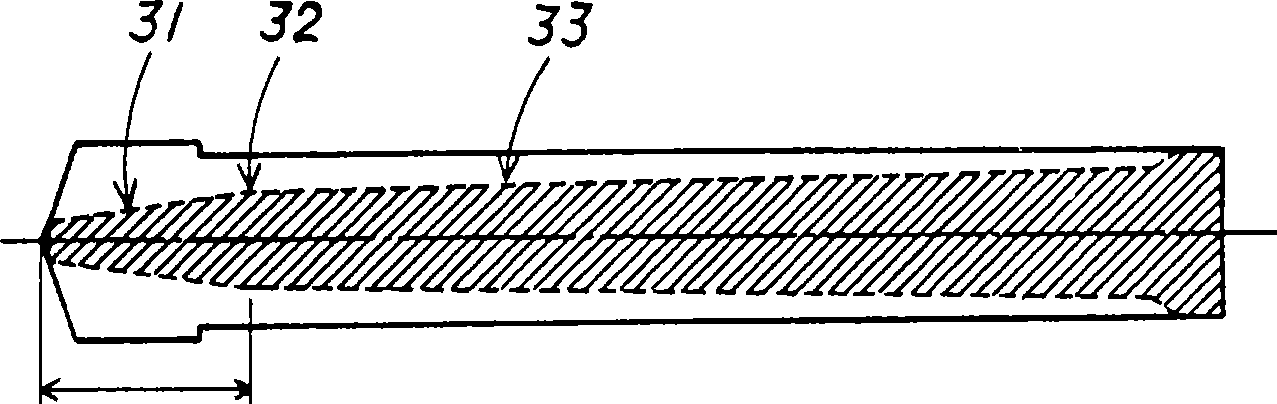

[0072] This embodiment is a drilling tool, the drilling tool is formed with one or more spiral chip removal grooves 2 from the front end of the tool toward the base end side on the outer periphery of the tool body 1, and the above chip removal grooves 2 include: first helix angle α 1 The first helical region 3; and the tool base end side of the first helical region 3 is continuously provided and has a ratio of the above-mentioned first helical angle α 1 Large second helix angle α 2 The second helical region 4 of the tool body 1 is configured such that the drill core thickness w gradually increases toward the base end side of the tool, and includes: a first tapered region 6 having a first drill core taper; The tool base end side of the region 6 is continuously provided and has a second tapered region 7 with a second core taper smaller than the first core taper, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com