Nodular graphite cast iron crankshaft of diesel engine and its non-feedhead casting process

A technology of nodular cast iron and casting process, applied in the field of riserless casting process, to achieve the effect of enhancing air permeability and heat dissipation, high rigidity, and strengthening the inoculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A riser-free casting process for a diesel engine nodular cast iron crankshaft, comprising the steps of:

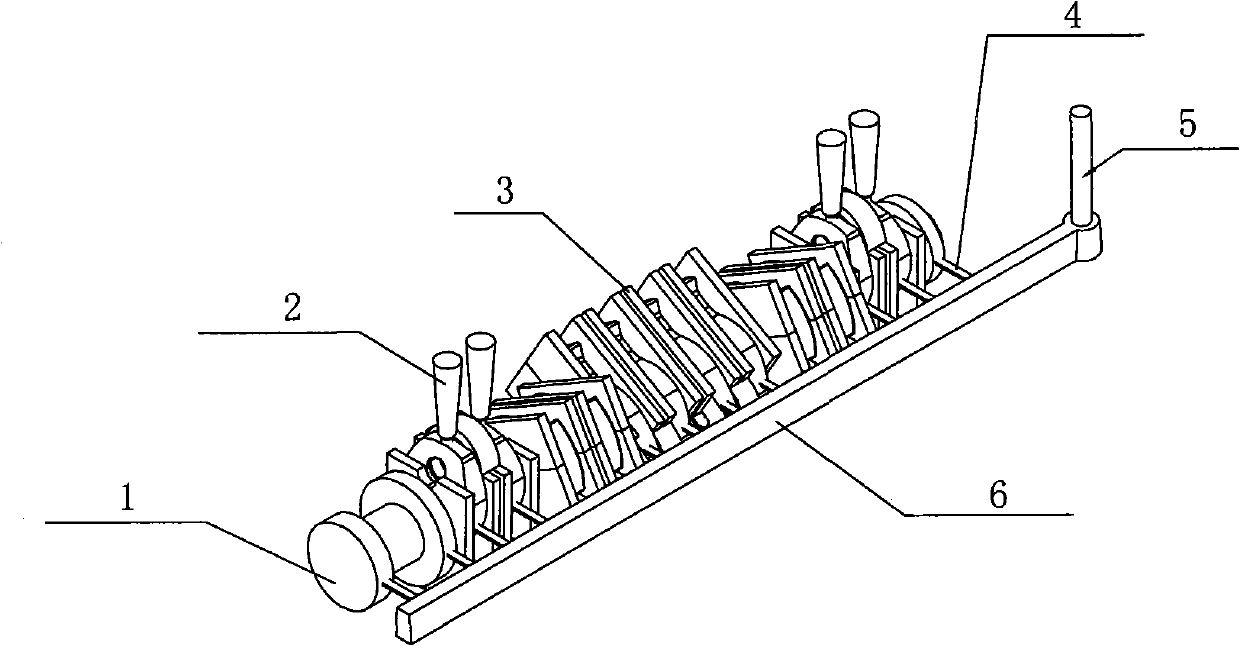

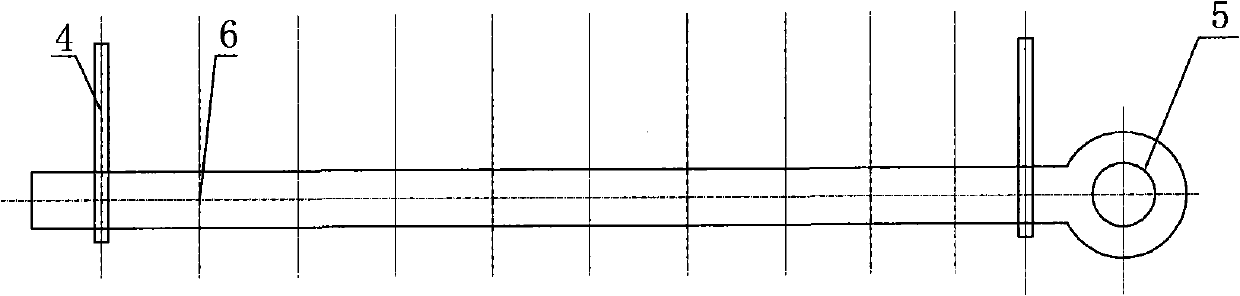

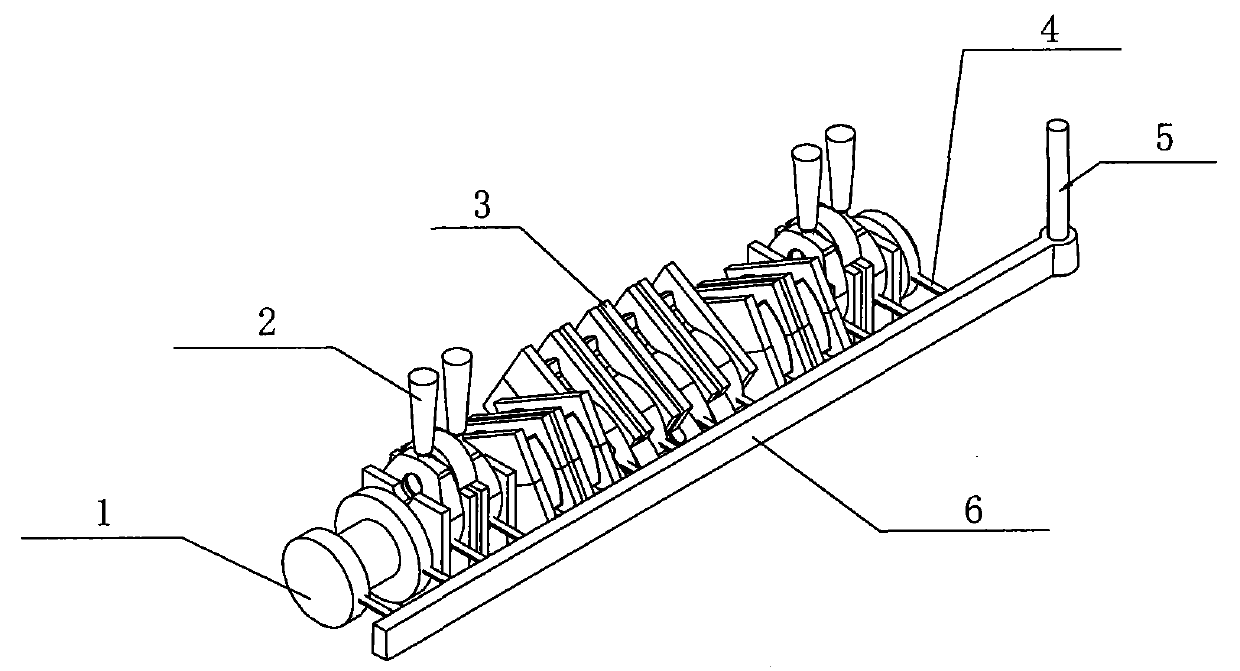

[0046] (1) Mold molding step: choose dry mold sand as the molding material to fill in the casting mold cavity, and set up an L-shaped pouring system on the sand body of the dry mold sand corresponding to the main shaft and the crankshaft of the crankshaft 1, such as figure 1 , figure 2 As shown, and the cold iron 3 is placed on the main shaft diameter part and the crankshaft diameter part of the crankshaft 1, the total weight of the cold iron 3 is about 1530Kg, and the pouring system is composed of a sprue 5, a runner 6 and a plurality of ingates 4, wherein The sprue 5 is connected to the runner 6, and a plurality of ingates 4 are arranged vertically to the runner 6 and respectively connected to the runner 6. There are also 7 cold risers on the sand body of the dry mold sand 3. The cross-sectional area ratio of the pouring system is: A 内 :A 横 :A 直 80:150:50; ...

Embodiment 2

[0057] A riser-free casting process for a diesel engine nodular cast iron crankshaft, comprising the steps of:

[0058] (1) Mold molding step: choose dry mold sand as the molding material and fill it in the casting mold cavity, set up an L-shaped pouring system on the sand body of the dry mold sand that is arranged at a position corresponding to the main shaft and the crankshaft of the crankshaft 1, and The main shaft diameter part and the crankshaft diameter part of the crankshaft 1 place the cold iron 3, and the total weight of the cold iron 3 is about 1530Kg. The runner 6 is connected, and a plurality of inrunners 4 are vertically arranged with the runner 6 respectively, and are respectively connected with the runner 6. There are also 7 cold risers 3 on the sand body of the dry mold sand, and the pouring system cuts The area ratio is: A 内 :A 横 :A 直 It is 85:160:60;

[0059] (2) Duplex smelting steps of ductile iron:

[0060] (2) Put pig iron, waste nodular cast iron an...

Embodiment 3

[0069] A riser-free casting process for a diesel engine nodular cast iron crankshaft, comprising the steps of:

[0070] (1) Mold molding step: choose dry mold sand as the molding material and fill it in the casting mold cavity, set up an L-shaped pouring system on the sand body of the dry mold sand that is arranged at a position corresponding to the main shaft and the crankshaft of the crankshaft 1, and The main shaft diameter part and the crankshaft diameter part of the crankshaft 1 place the cold iron 3, and the total weight of the cold iron 3 is about 1530Kg. The runner 6 is connected, and a plurality of inrunners 4 are vertically arranged with the runner 6 respectively, and are respectively connected with the runner 6. There are also 7 cold risers 3 on the sand body of the dry mold sand, and the pouring system cuts The area ratio is: A 内 :A 横 :A 直 It is 95:170:70;

[0071] (2) Duplex smelting steps of ductile iron:

[0072] (2a) Put pig iron, waste nodular cast iron a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com