Z-notch shape for a turbine blade

A technology of turbines and vanes, applied in the direction of supporting elements of blades, mechanical equipment, engine manufacturing, etc., which can solve problems such as maintenance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

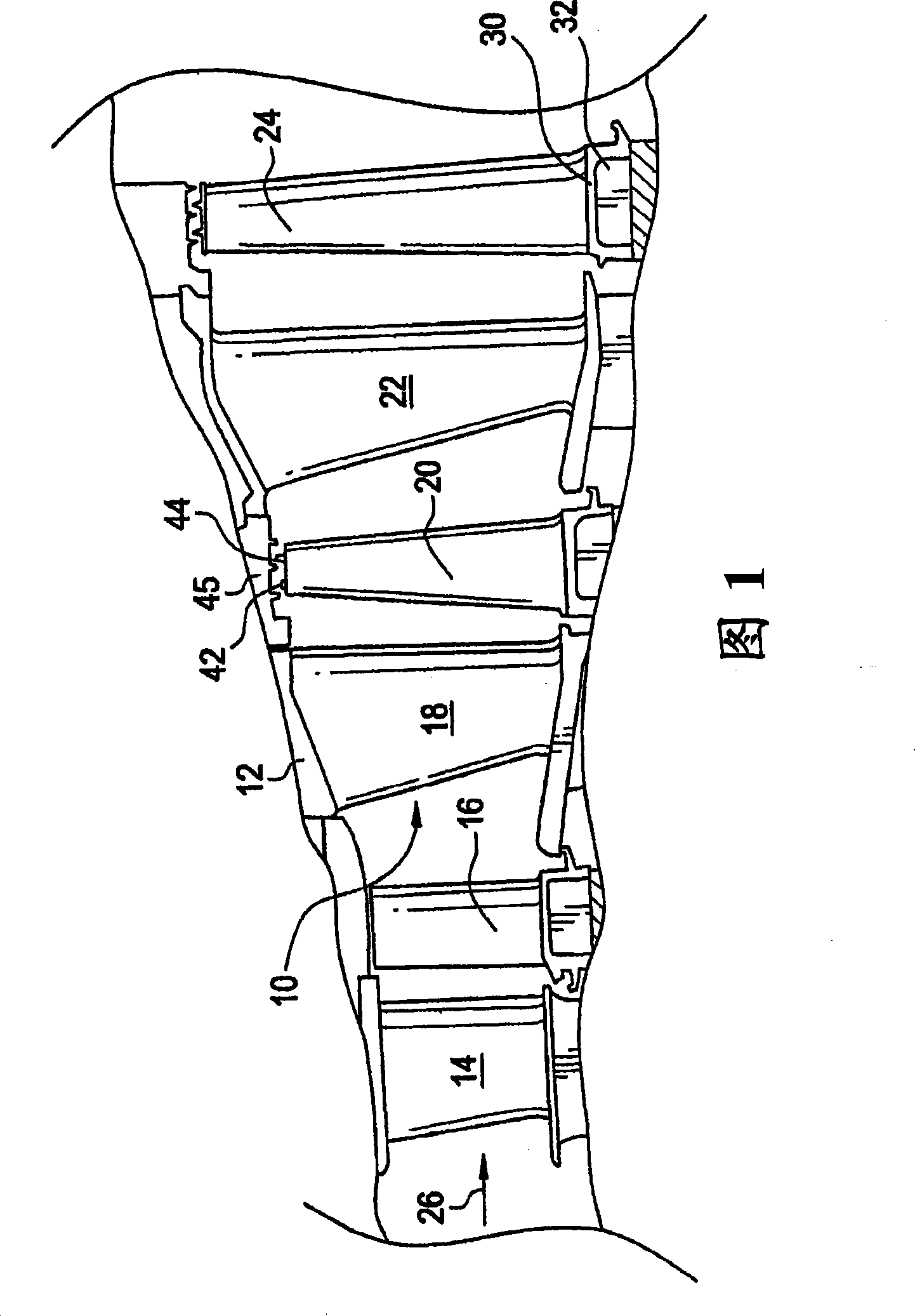

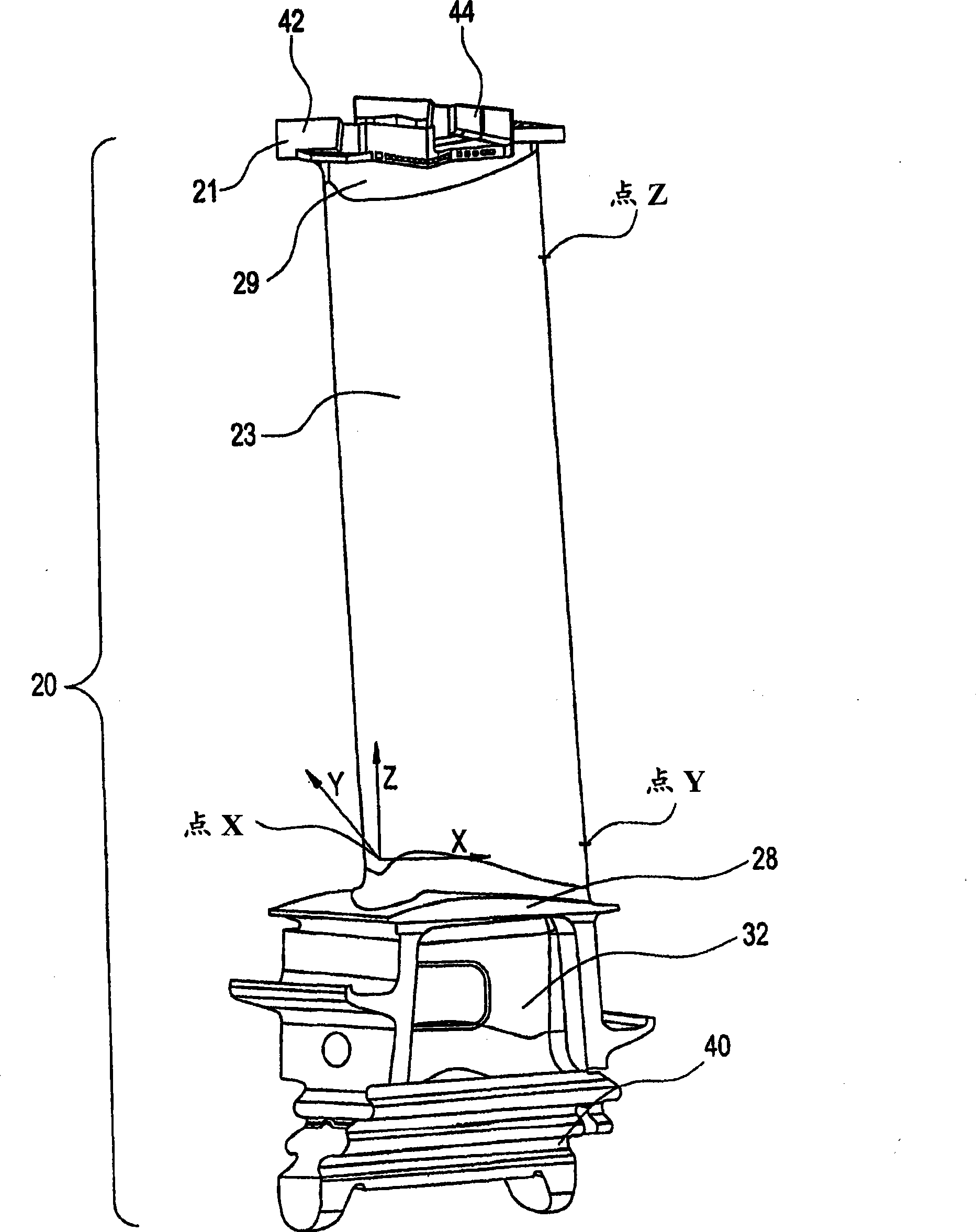

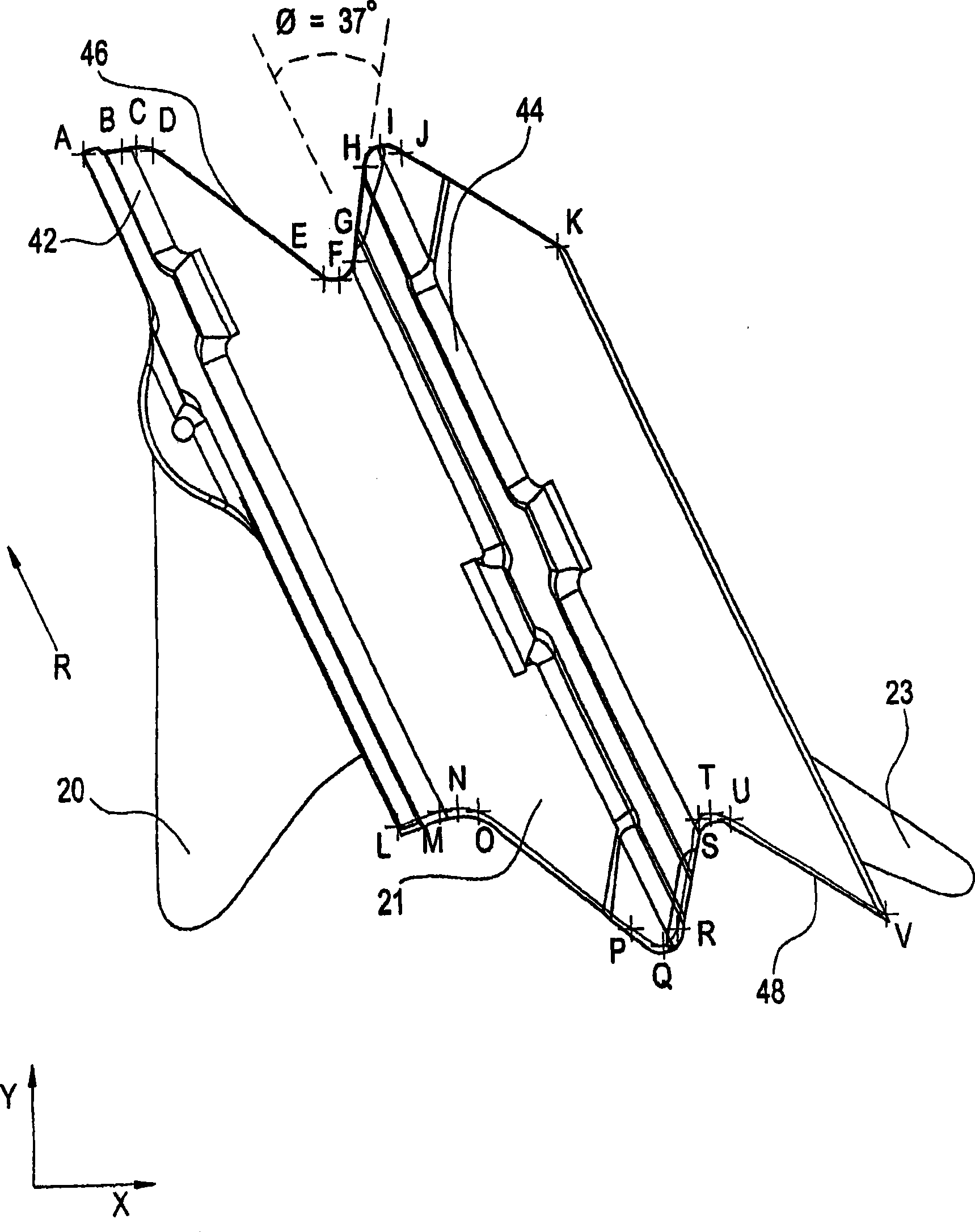

[0031] Disclosed is a design for a tip shroud for a turbine bucket. Known as the "Z-notch" design (or Z-notch profile), this design creates an interlocking condition between adjacent buckets during operation, providing engagement of adjacent buckets while reducing stress. The Z-notch design may be said to include a "Z-shaped profile". Among other things, the shaped profile of the Z-notch provides improved contact interaction between turbine blades in high-pressure turbines; improved mechanical blade loading under engine operating conditions; improved mass distribution in the tip shrouds, and Z-shape Improved control of any gaps between adjacent shrouds in the gap area. Some definitions are given before a detailed discussion of the embodiments.

[0032] The term "gas turbine" refers to a continuous combustion engine. In the exemplary embodiment, a gas turbine generally includes a compressor, a combustor (referred to as a "combustor"), and a turbine. During operation, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com