Diesel engine throttle position detection method and detection apparatus

A technology of throttle position and detection method, which is applied in the direction of measuring devices, mechanical equipment, engine control, etc., can solve problems such as the influence of throttle opening signals, achieve the effects of easy measurement, improved detection accuracy, and reduced calibration times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

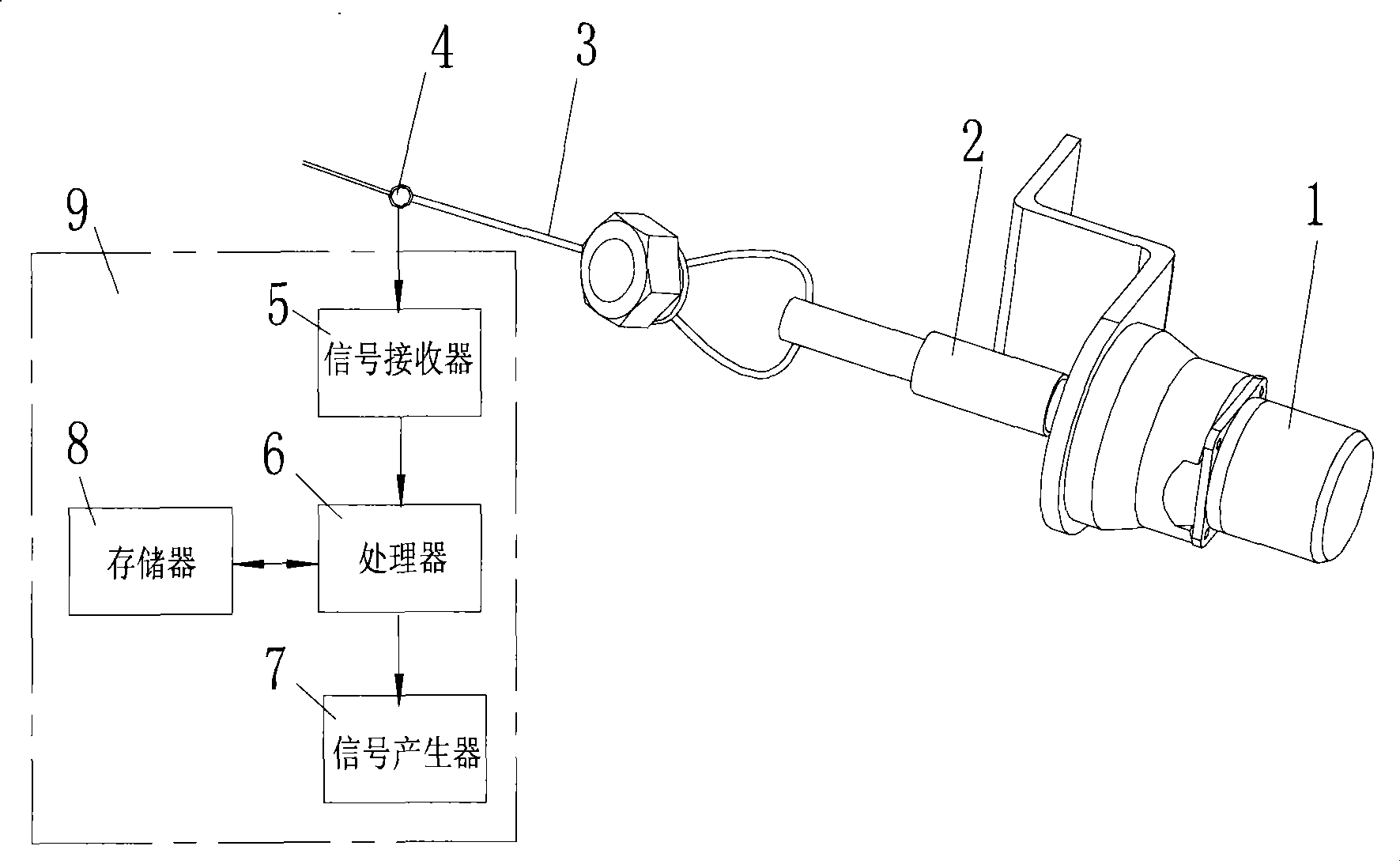

[0025] The basic idea of the present invention is to determine the position of the throttle by acquiring the tension on the steel wire rope connecting the stepper motor transmission mechanism and the speed regulating pull rod of the throttle.

[0026] The following will be described in detail in conjunction with the accompanying drawings and embodiments.

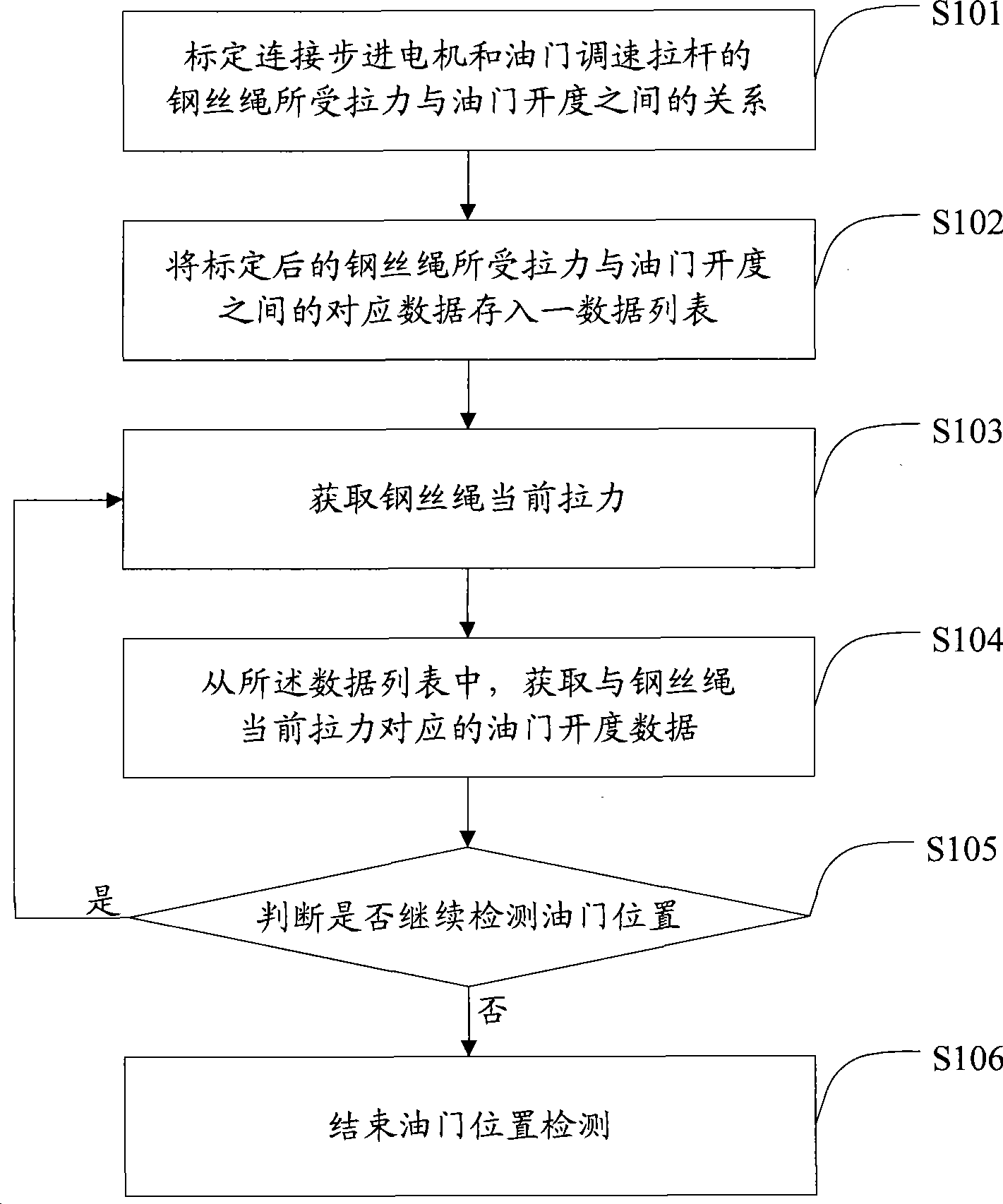

[0027] See figure 1 , which is a flow chart of the method for detecting the throttle position of a diesel engine in the present invention. The detection method comprises the following steps:

[0028] S101. Calibrate the relationship between the tensile force on the steel wire rope connecting the stepping motor transmission mechanism and the throttle speed regulating rod and the throttle opening.

[0029] There is a one-to-one correspondence between the tension on the wire rope and the throttle opening, and the key is to determine the correspondence, but the analytical function form between the two is difficult to obtain,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com