Inverse defrosting method for air supply heat pump

A reverse defrosting and heat pump technology, applied in heat pumps, lighting and heating equipment, compressors with reversible cycles, etc., can solve problems affecting performance, wasting energy, affecting heat transfer of evaporators, etc., to achieve energy efficiency ratio optimization and saving energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Example of reverse defrosting device:

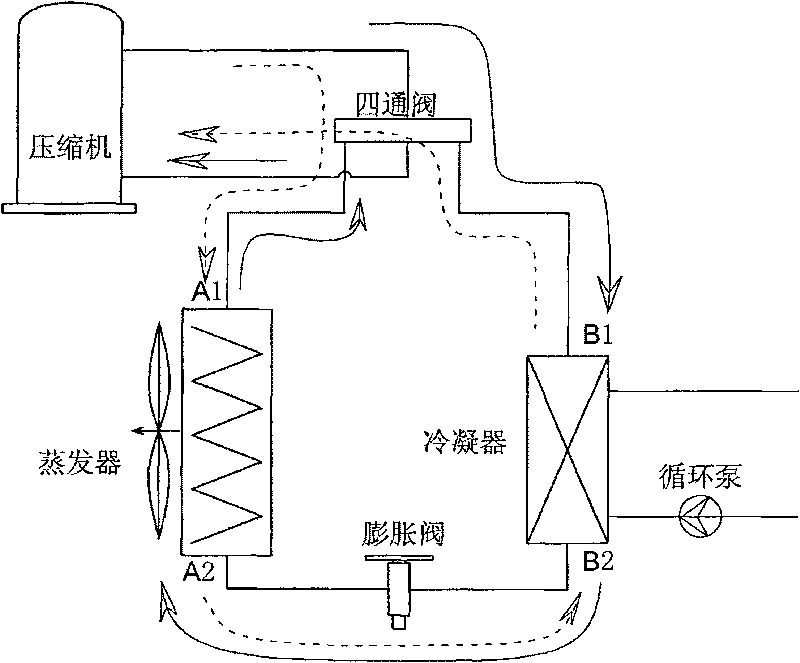

[0025] Such as figure 1 , which is a schematic structural diagram of an embodiment of the reverse defrosting device of the present invention. The air source heat pump includes a controller, a compressor, an evaporator, an expansion valve, a condenser and a circulating pump, and an electric-controlled four-way valve is connected in series between the outlet and the inlet of the compressor, and the electric-controlled four-way valve The other two interfaces of the condenser are respectively connected to the refrigerant ports A1 and B1 of the condenser and the evaporator, and the other refrigerant ports A2 and B2 of the condenser and the evaporator are connected to each other through the expansion valve, and the controller is respectively connected to The switching circuit of the electronically controlled four-way valve, compressor, evaporator, and circulating pump is characterized in that: the reverse defrosting method includes: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com